A non-post-curing epoxy resin casting system

An epoxy resin and casting system technology, which is applied in the field of non-post-curing epoxy resin casting systems, can solve problems such as heavy labor intensity, high energy consumption, and impact on product delivery time, and achieve high production efficiency, simple production process, and guaranteed The effect of quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0063] At room temperature, add 10% LLQ8040, 0.5% K560 and 0.5% DY062 accelerator into 89% DER331, stir at room temperature for about 80 minutes, and set aside. Dissolve 0.8% DCMU-99 N-(3,4 dichlorophenyl)-N,N-dimethylurea in LLQ1225 at 80 degrees, cool to room temperature for use. Then mix the above formula toughened epoxy resin, formula toughened anhydride curing agent and 400 mesh active quartz powder according to 100:100:380 at 40°C for 1 hour, vacuumize for 1.5 hours, mold temperature 150°C, vacuum degree 4.5mbar , Hold pressure at 160°C for 15 minutes, demoulding to obtain an insulator without post-curing. The glass transition temperature of the DSC curve test is 85°C, and there is no obvious exothermic curve above 100°C. -40°C-80°C cold and heat cycle 3 times without any cracking.

Embodiment example 2

[0065] Add 5% ATBN 1300×21, 0.2% K560 and 0.8% DMP30 accelerator into 94% DER331, stir at room temperature for about 80 minutes, and set aside. React 10% polyethylene glycol 200 and 89.5% methyltetrahydrophthalic anhydride at 150°C for 1.5 hours, cool to room temperature, add 0.5% 2-ethyl-4 methylimidazole, stir for 30 minutes, cool to room temperature for use . Then mix the above formula toughened epoxy resin, formula toughened anhydride curing agent and 400 mesh active quartz powder according to 100:100:350 at 40°C for 1 hour, vacuumize for 1.5 hours, mold temperature 150°C, vacuum degree 4.5mbar , Hold pressure at 150°C for 30 minutes, demoulding to obtain a transformer without post-curing. The glass transition temperature of the DSC curve test is 82°C, and there is no obvious exothermic curve above 100°C. -50°C-120°C cold and heat cycle 5 times without any cracking.

[0066]

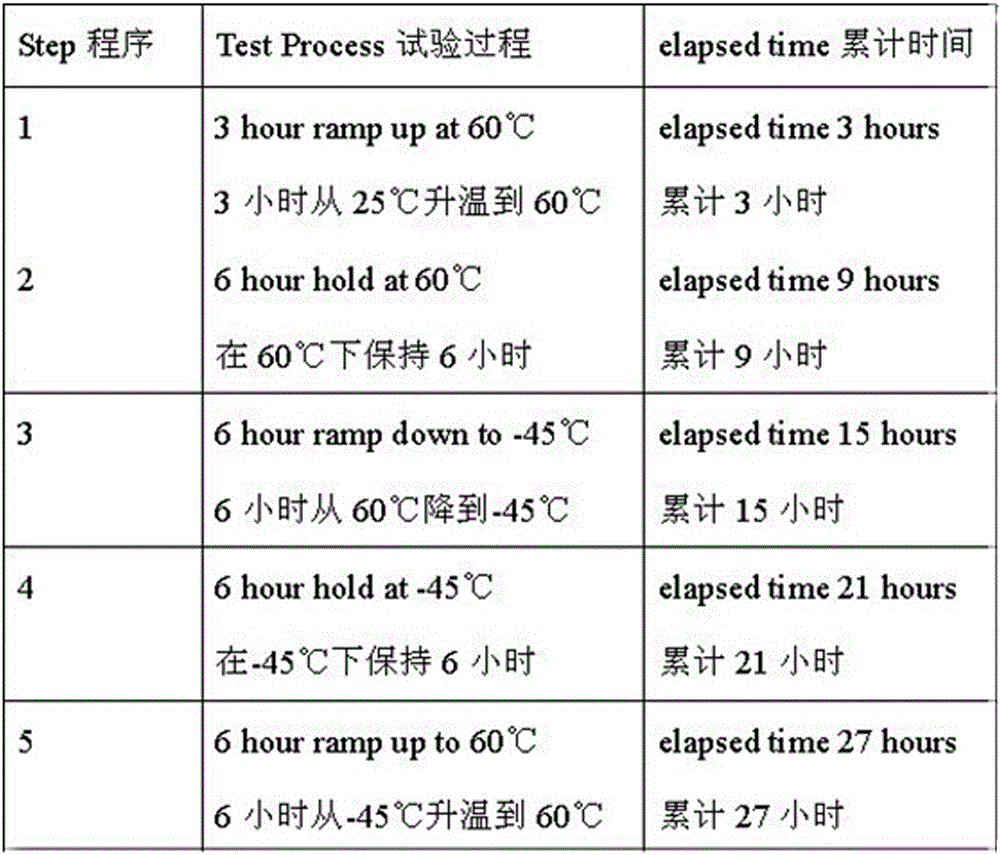

[0067] The above table is the cold and hot cycle report of the non-post-cured epoxy casting...

Embodiment example 3

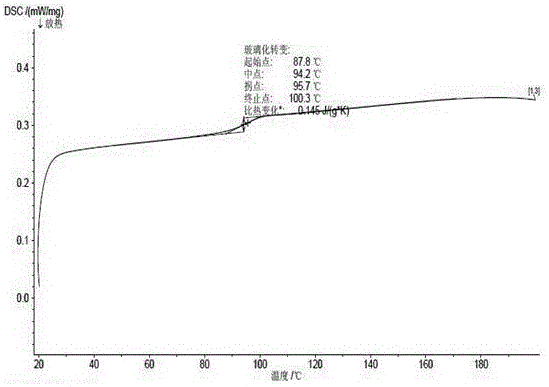

[0069] At 80°C, add 0.2% aluminum acetylacetonate accelerator to 89.3% DER331 to dissolve, then cool to room temperature, add 15% PPGDGE, 0.5% K560 to the above mixture, stir for 1 hour, and set aside. Dissolve 0.5% organic urea accelerator Dyhard UR 500 in LLQ 1227 at 80 degrees, cool to room temperature for use. Then mix the above formula toughened epoxy resin, formula toughened anhydride curing agent and 400 mesh active quartz powder according to 100:100:400 at 40°C for 1 hour, vacuumize for 1.5 hours, mold temperature 150°C, vacuum degree 4.5mbar , Hold pressure at 150°C for 20 minutes, demoulding to get a casing without post-curing. The glass transition temperature of the DSC curve test is about 96°C, and there is no obvious exothermic curve above 100°C. -40°C-80°C cold and heat cycle 3 times without any cracking.

[0070] refer to figure 1 , the DSC table of the non-post-cured epoxy casting product produced in the implementation case three, as can be seen from the tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com