A preparation method of 4D printing copper-based shape memory alloy and 4D printing copper-based shape memory alloy

A memory alloy, 4D technology, applied in the field of 4D printing copper-based shape memory alloys, can solve the problems of limiting the application of CuAlMn shape memory alloys, poor shaping of CuAlMn shape memory alloys, large elastic anisotropy, etc., to improve the resistance to high temperature oxidation ability, reducing alloy cracking behavior, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare a new CuAlMn copper alloy composition 4D printing metal powder, and prepare it according to the mass percentage content, as follows: Al: 20%; Mn: 10%; Si: 0.3%; Ni: 0.3%; Zn: 0.1%; Mg: 0.05% ; Ti: 0.15%; Zr: 0.1%; Sc: 0.1%; the rest is copper.

[0030] Vacuum smelting: put the above-mentioned 4D printed ordinary copper alloy raw material pure metal block into a vacuum induction furnace for heating and smelting; the melting temperature of vacuum smelting is 1150°C, and the pressure in the furnace is 0.4MPa; atomized powder making uses nitrogen as the medium, The gas pressure is 4MPa.

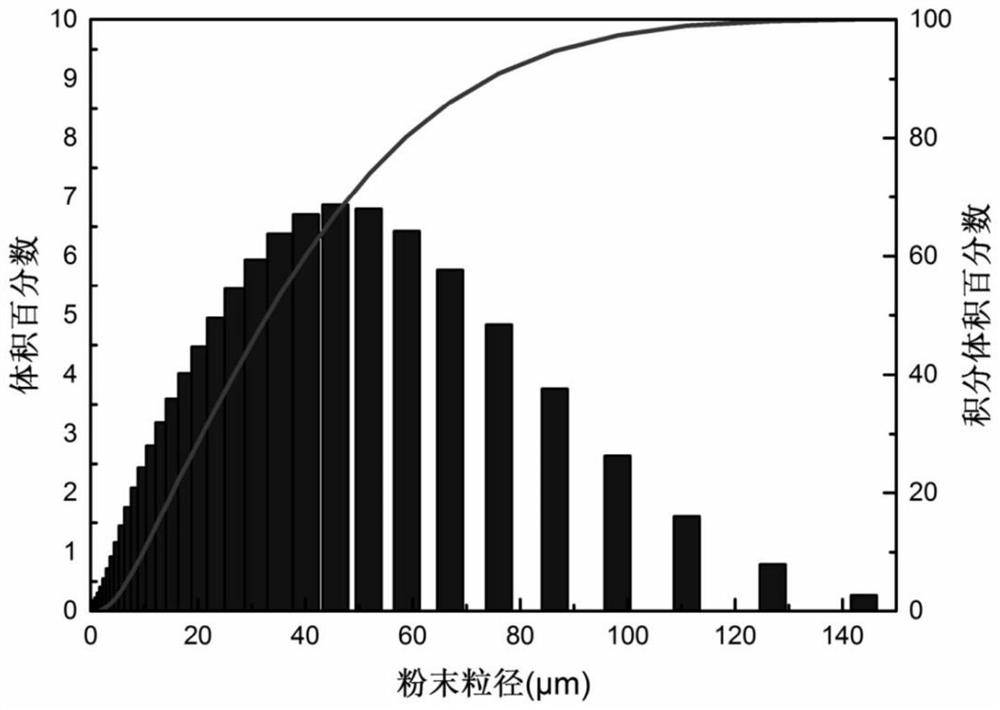

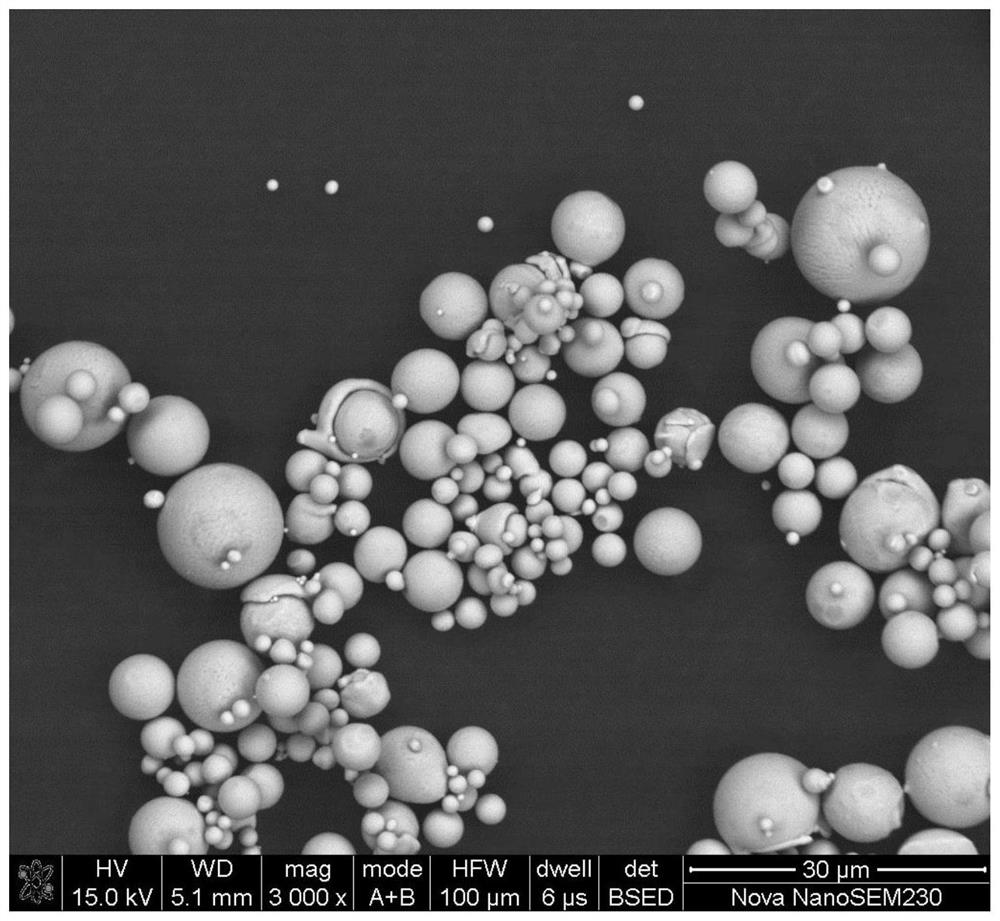

[0031] Atomized powder making: using nitrogen as the medium, the molten metal after vacuum smelting is atomized and powdered to obtain copper alloy pre-alloyed powder;

[0032] Powder sieving treatment: pass the obtained powder through a 250-mesh sieve for sieving treatment;

[0033] Drying treatment: place the sieved copper alloy powder in a drying oven for drying, the drying te...

Embodiment 2

[0037] Prepare a new CuAlMn copper alloy composition 4D printing metal powder, and prepare it according to the mass percentage content, as follows: Al: 23%; Mn: 11%; Si: 0.5%; Ni: 0.6%; Zn: 0.2%; Mg: 0.15% ; Ti: 0.25%; Zr: 0.13%; Sc: 0.13%; the rest is copper;

[0038] Vacuum smelting: put the above-mentioned 4D printed common copper alloy raw material pure metal block into a vacuum induction furnace for heating and smelting; the melting temperature is 1150°C, and the pressure in the furnace is 0.4MPa;

[0039] Atomized pulverization: using nitrogen as the medium, atomize the molten metal after vacuum melting to obtain copper alloy pre-alloyed powder; atomized pulverization uses nitrogen as the medium, and the gas pressure is 4MPa;

[0040] Powder sieving treatment: pass the obtained powder through a 250-mesh sieve for sieving treatment;

[0041] Drying treatment: place the sieved copper alloy powder in a drying oven for drying, the drying temperature is 100° C., and the hold...

Embodiment 3

[0045] Prepare a new CuAlMn copper alloy composition 4D printing metal powder, and prepare it according to the mass percentage content, as follows: Al: 24%; Mn: 12%; Si: 0.7%; Ni: 0.8%; Zn: 0.3%; Mg: 0.2% ;Ti: 0.3%; Zr: 0.15%; Sc: 0.15%; the rest is copper;

[0046] Vacuum smelting: put the above-mentioned 4D printed common copper alloy raw material pure metal block into a vacuum induction furnace for heating and smelting; the melting temperature is 1150°C, and the pressure in the furnace is 0.4MPa;

[0047] Atomized powder making: using nitrogen as the medium, atomize the molten metal after vacuum smelting to obtain copper alloy pre-alloyed powder; atomized powder using nitrogen as the medium, and the gas pressure is 4MPa.

[0048] Powder sieving treatment: pass the obtained powder through a 250-mesh sieve for sieving treatment;

[0049] Drying treatment: place the sieved copper alloy powder in a drying oven for drying, the drying temperature is 100° C., and the holding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com