Method for preparing electrocatalytic coating by using plasma

A plasma and electrocatalysis technology, applied in the field of electrochemistry, can solve the problems of oxidation, deactivation, iridium-based oxide peeling of titanium substrates, etc., to reduce cracking behavior, enhance catalytic activity, and alleviate the electrochemical oxidation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

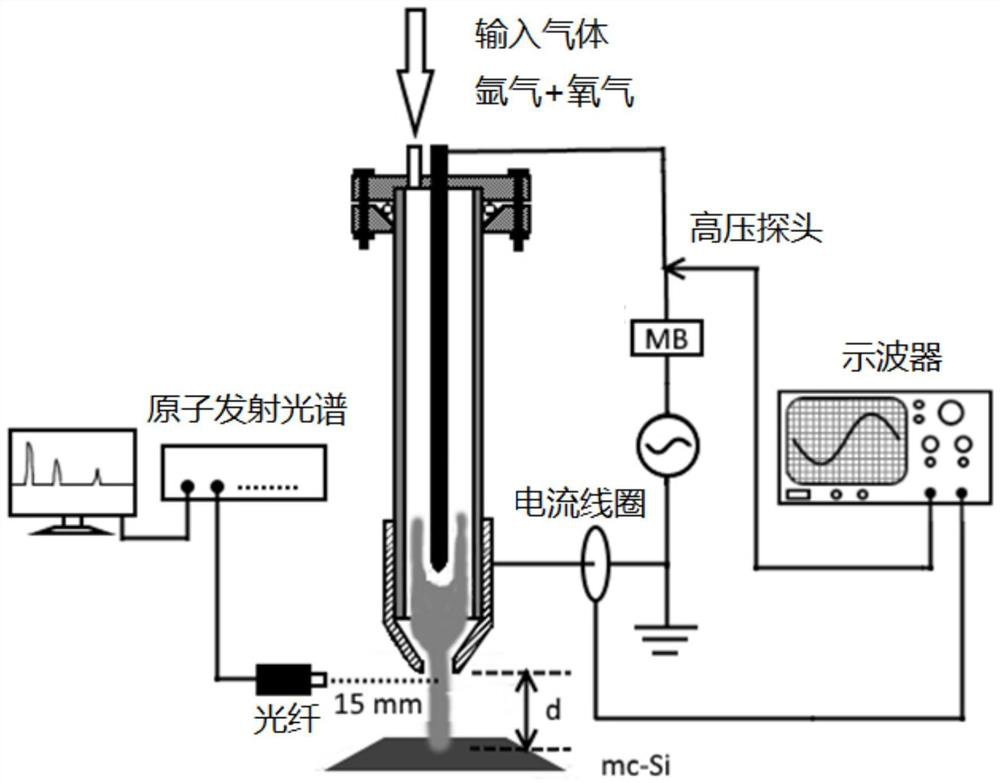

[0031] As a preferred example, the present invention takes the preparation of the iridium cobalt oxide coating as an example, and the radio frequency plasma jet excited by 2MHz is used as a preparation tool to illustrate the preparation method of the electrocatalytic anode coating, and carry out a series of experiments with the prepared anode coating Test to verify the effectiveness of the preparation method. use as figure 1 The radio frequency plasma jet shown is used for the preparation of iridium cobalt oxide coating, the main experimental steps are as follows:

[0032] 1. Treat the cut titanium sheet with conventional cleaning and surface treatment methods, and air dry it for later use;

[0033] 2. Connect the plasma jet device excited by radio frequency. The input gas is argon. A certain amount of oxygen is introduced into the plasma; or compressed air is directly used as the reactive gas of the plasma. figure 1 is a schematic diagram of a plasma jet excited by radio f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com