Printer with automatic filtering function

An automatic filter and printer technology, applied in the direction of printing devices, printing, etc., can solve the problems of shortening the service life of the printer, affecting work efficiency, and not having any detection, so as to achieve the effects of easy promotion and use, improvement of work efficiency, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

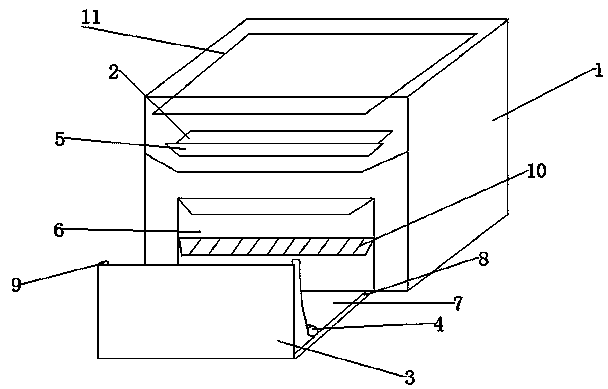

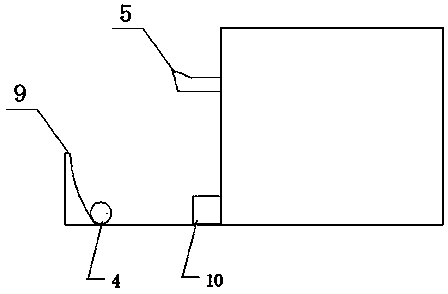

[0014] Example 1, see figure 1 , figure 2 , an automatic filter printer, the printer includes a machine box body body 1, a paper input device 6, a paper output device 2, and a paper output tray 5, the paper input device 6 is located at the bottom of the machine box body 1, and the paper input device 6 The opening of device 6 is rectangular, and described paper input device 6 communicates with the inside of described machine box body 1, and described paper output device 2 is positioned at described machine box body 1 top and communicates with machine box body 1 inside, and described paper output The tray 5 is located below the paper feeding device 6 , and the printer further includes a filter device 10 , and the filtering device 10 is arranged on the paper feeding device 6 . The filter device ensures that other foreign matter is discharged before the paper enters, avoiding paper jams caused by other foreign matter, and at the same time, the filter device also helps to impro...

Embodiment 2

[0015] Example 2, see figure 1 , figure 2 , as an improvement of the present invention, the printer also includes a paper support board, the paper support board is composed of a vertical board 3 and a horizontal board 7, and the vertical board 3 and the horizontal board 7 are connected in an "L" shape, close to the vertical board The paper feed roller is installed at the 3rd position, and the motor is housed in the paper feed roller, and the paper feed roller is closely attached to the horizontal plate 7, and the paper is sent into the machine box body with the rotation of the motor. The rest of the structures and advantages are exactly the same as in Embodiment 1.

[0016]

Embodiment 3

[0017] Example 3, see figure 1 , figure 2 , as an improvement of the present invention, there are chutes 8 on both sides of the horizontal plate, arc-shaped paper clamping grooves 9 on both sides of the vertical plate, the depth of the chute is 3-5mm, and the clamping The width of the paper slot is 1-2 mm; the filter device is set as a filter brush. The filter brush is made of PVC material, so there is no risk to the printing paper. The rest of the structures and advantages are exactly the same as in Embodiment 1.

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com