Standard brick stacking automatic line

An automatic line and stacking technology, which is applied in the field of standard brick stacking of engineering building materials, can solve the problems of dirty and tiring, many personnel required, physical labor and other problems, and achieves the effect of strong mobility, convenient use and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

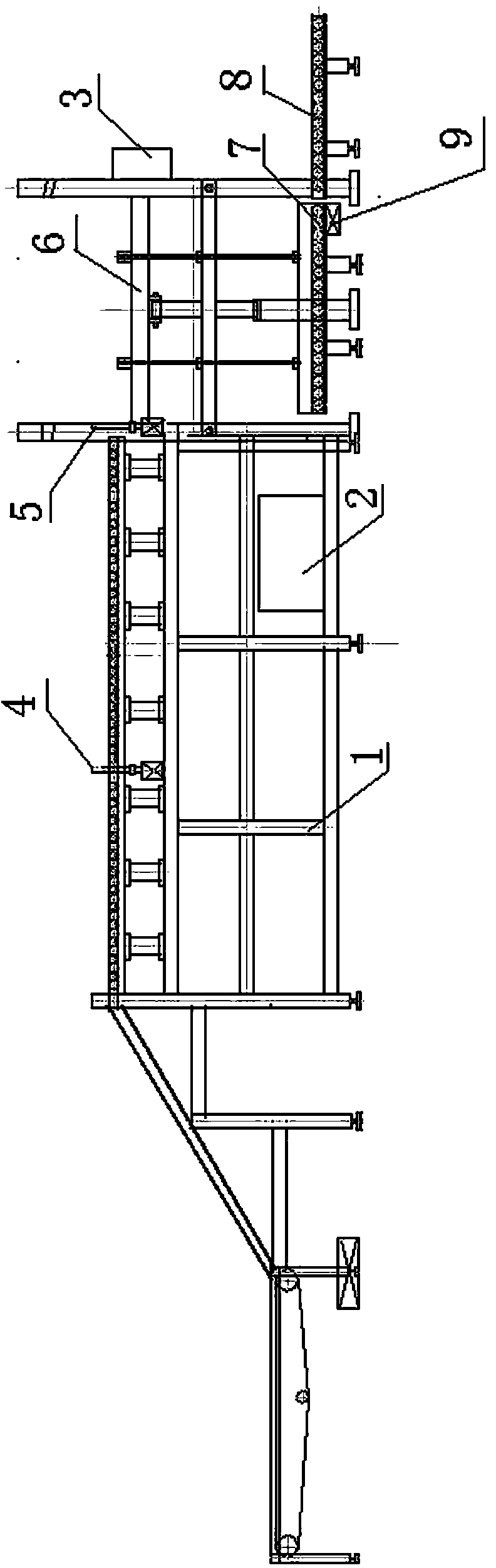

[0018] Such as figure 1 shown. Rack 1, electrical operation control cabinet 2, touch-mode operation panel 3, second push rod solenoid valve 4, fourth cylinder bar 5, hydraulic hoist 6, second power raceway 7, non-power raceway 8, first Four reducers9.

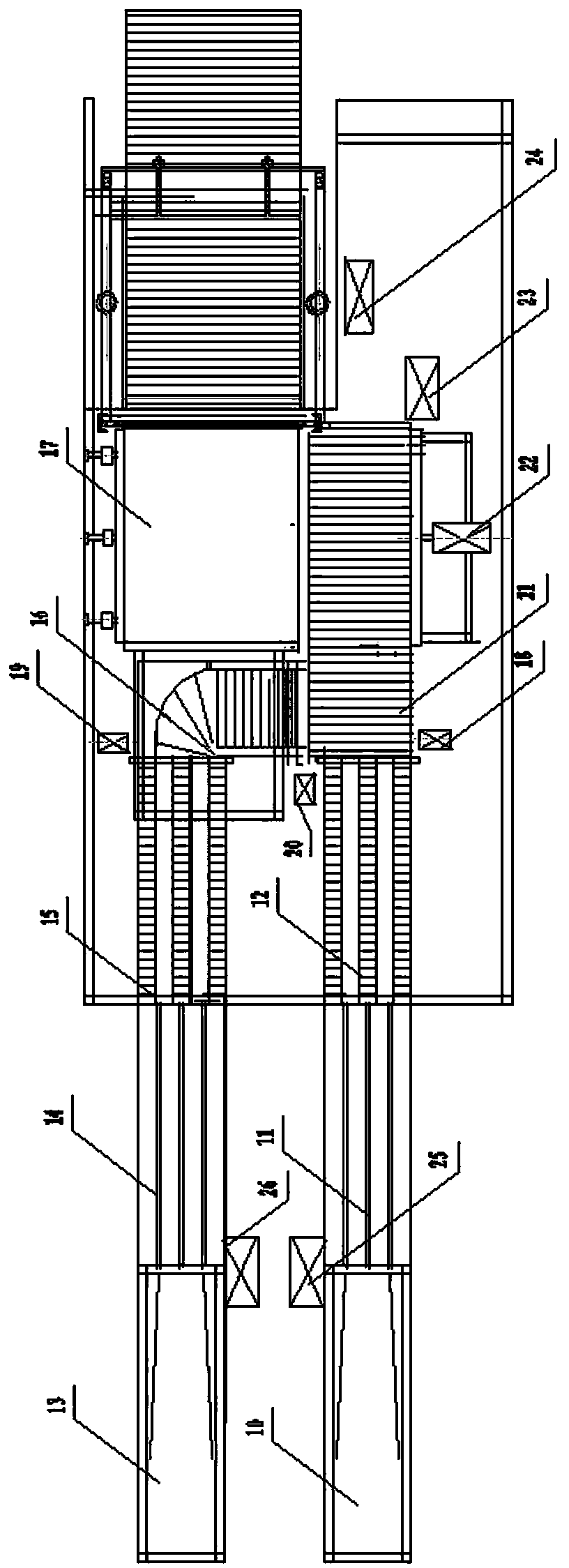

[0019] Such as figure 2 shown. The first horizontal belt conveyor 10, the first slope elevator 11, the first conveyor raceway 12, the second horizontal belt conveyor 13, the second slope elevator 14, the second conveyor rollerway 15, the turning conveyor rollerway 16, push rod Combined platform 17, first cylinder bar 18, second cylinder bar 19, third cylinder bar 20, first power raceway 21, first cylinder push rod 22, third reducer 23, hydraulic station 24, the first One speed reducer 25, the second speed reducer 26.

[0020] The present invention consists of an electrical control cabinet 2, a touch ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com