Displacement adjustment device for separating knife on spinning preparation machine and its application method

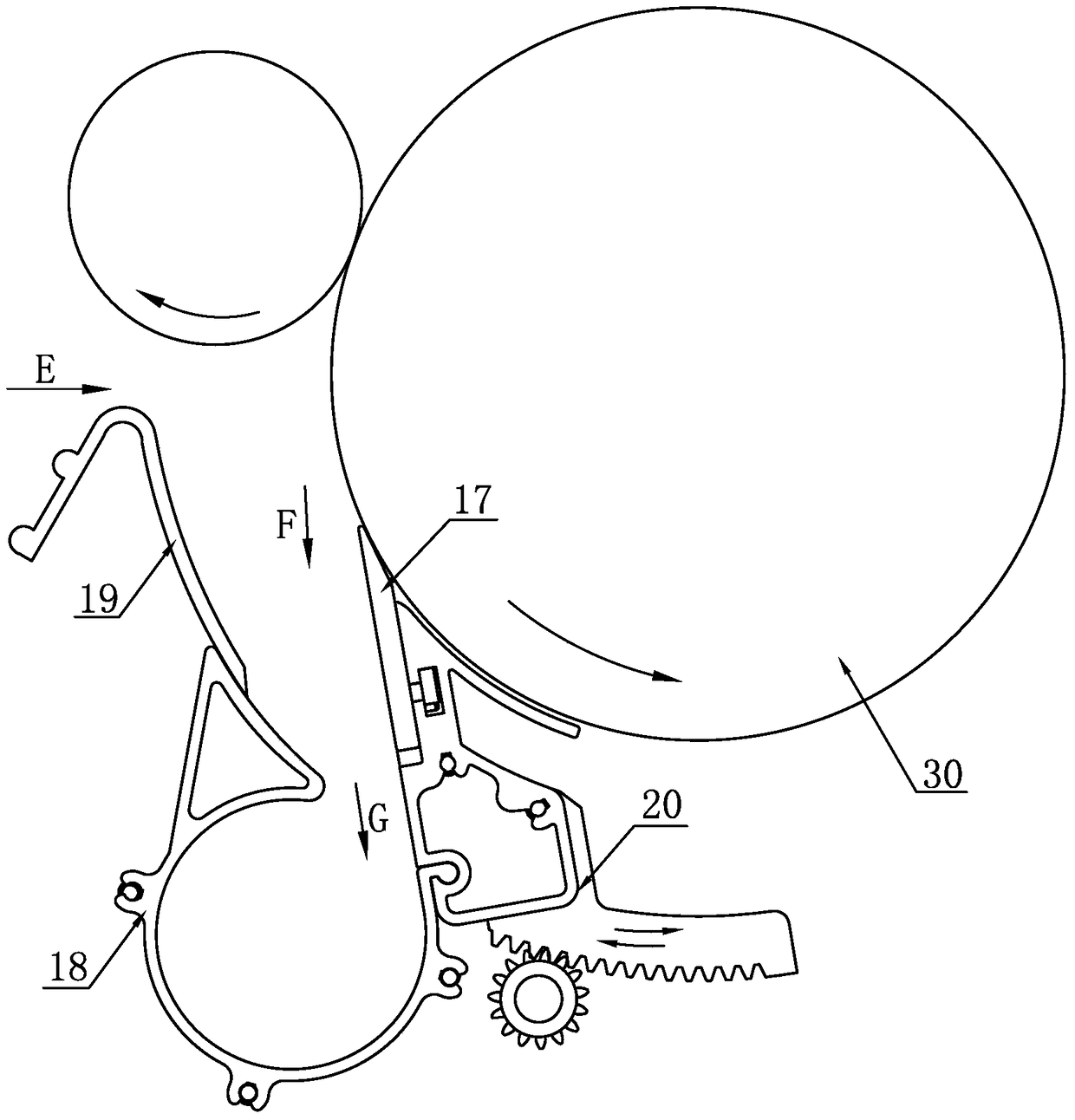

A technology for regulating devices and separating knives, which is applied in the direction of deburring devices, textiles and papermaking, fiber cleaning machines, etc., and can solve the problems of complex structures of fixing elements 19 and discharge chambers 18, affecting the effects of impurity removal and exhaust, and increasing frictional resistance. Large and other problems, to achieve the effect of simple structure, light displacement adjustment, and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

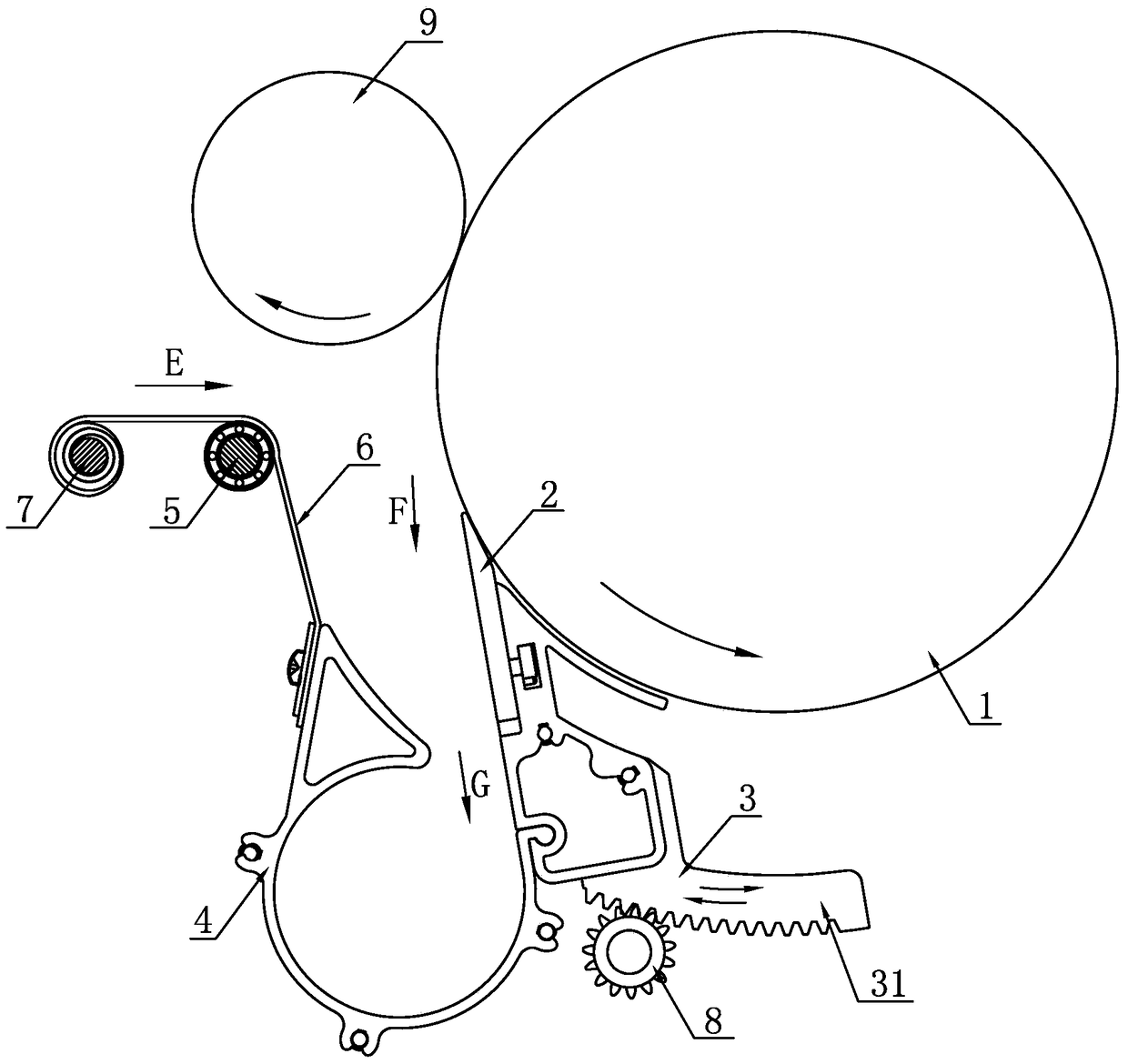

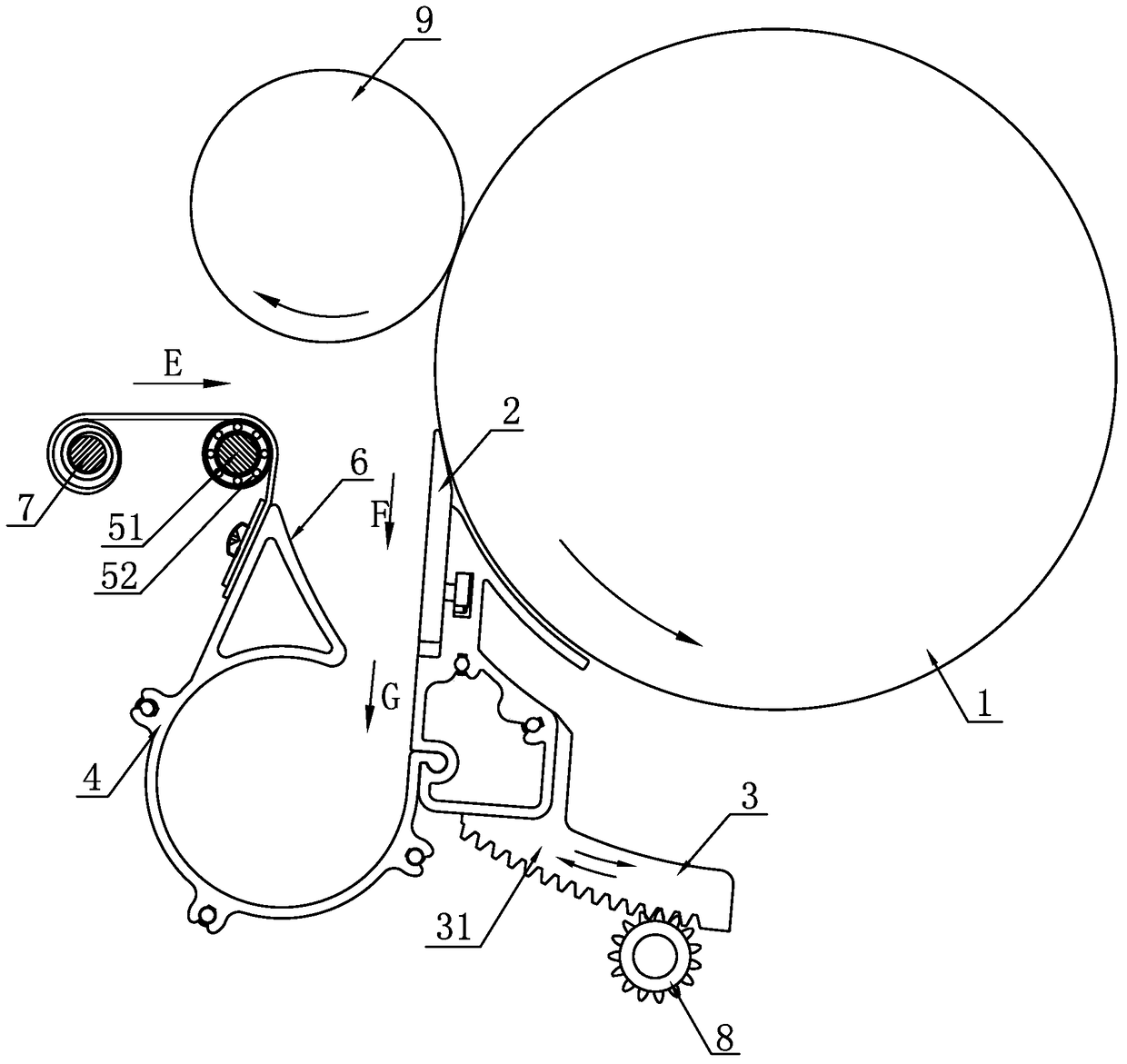

[0020] Embodiment 1: A separation knife displacement adjustment device on a spinning preparation machine, including a separation roller 1, a separation knife body 2, a rotating knife holder 3, a dust receiving cylinder 4, a rolling shaft 5, a winding plate 6, an automatic winding Rolling mechanism 7 and adjusting gear 8, separating cutter body 2 is installed on the rotating knife rest 3, and this rotating knife rest 3 can move along the circumference of separation roller 1, is provided with ring gear 31 at the lower end of rotating knife rest 3, and adjusting gear 8 It meshes with the ring gear 31 on the rotating tool holder 3, the tip of the separating knife body 2 is tangent to the outer circumference of the separating roller 1, the dust-collecting cylinder 4 is installed on the rotating tool holder 3, and one end of the winding plate 6 is fixed At the opening end of the dust receiving cylinder 4, one end of the winding plate 6 is connected with the automatic winding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com