Water face thin oil film recycling and separating device

A technology of separation device and thin oil film, which is applied in the direction of separation method, liquid separation, grease/oily substance/floating matter removal device, etc., which can solve the problems of small oil sweeping surface, poor effect and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

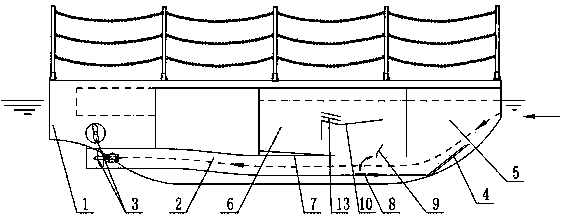

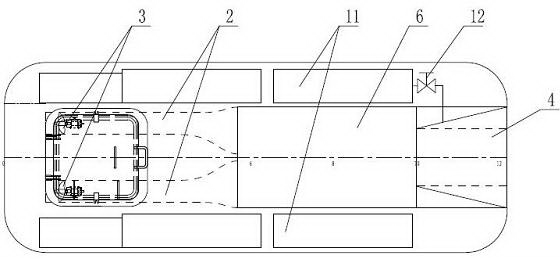

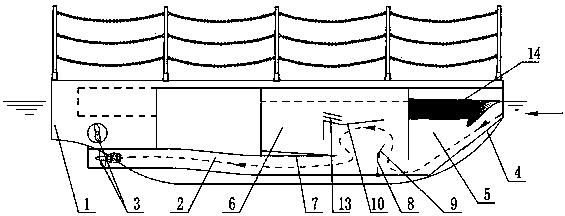

[0021] See figure 1 , figure 2 , the present invention comprises a hull 1, the hull 1 is provided with a main channel 2 for the entry and passage of oily water, the main channel 2 extends from the bow of the hull 1 to the stern, the entrance of the main channel 2 is located at the bow of the hull 1, the main channel The outlet of channel 2 is located at the stern of hull 1, the entrance of main channel 2 is higher than the outlet of main channel 2, and the stern of hull 1 is provided with propulsion device 3; An adjustment cofferdam 4 is arranged on it, which is used to adjust the entrance of the main channel 2 according to the incoming flow velocity, thereby adjusting the flow velocity at the entrance of the main channel 2. The flow velocity at the entrance can be calculated according to the flow rate of the main channel 2, specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com