A high-strength steel transmission tower with a honeycomb structure

A technology of honeycomb structure and transmission tower, which is applied in basic structure engineering, tower, building type, etc., can solve the problems of difficult welding of high-strength steel pipes, limited thickness of high-strength steel pipes, and inability to guarantee welding quality, etc., to increase local stability, improve Overall bearing capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

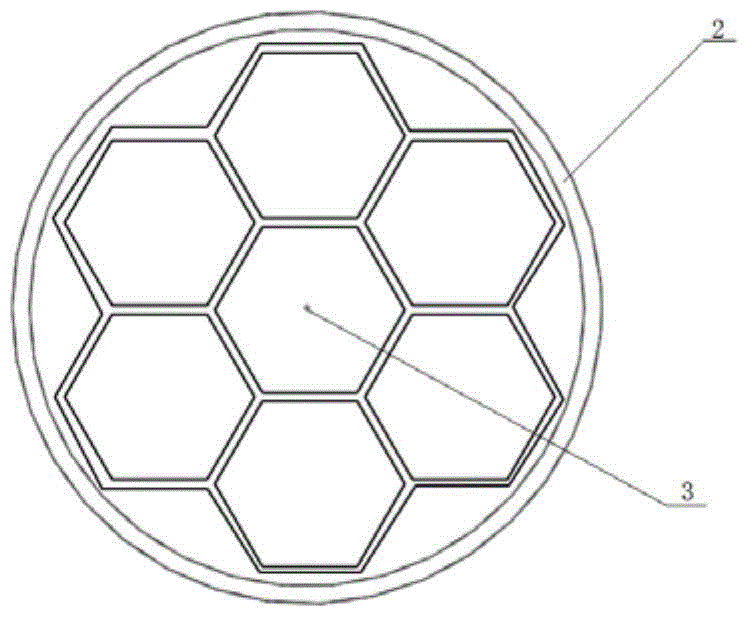

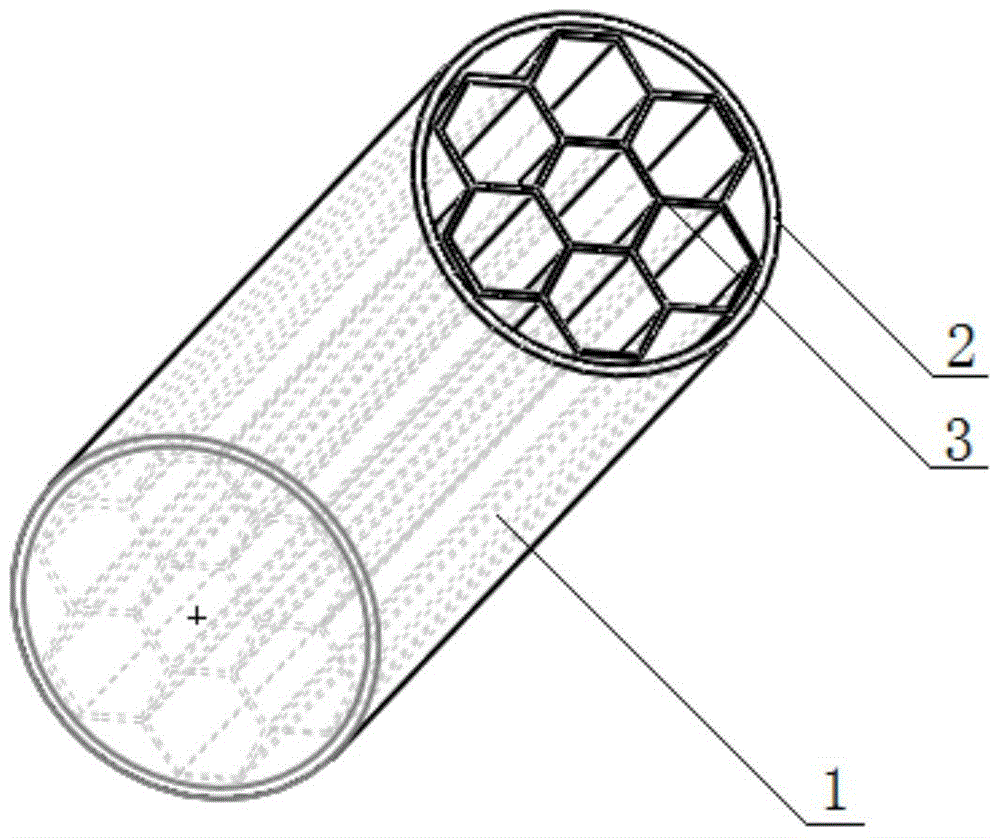

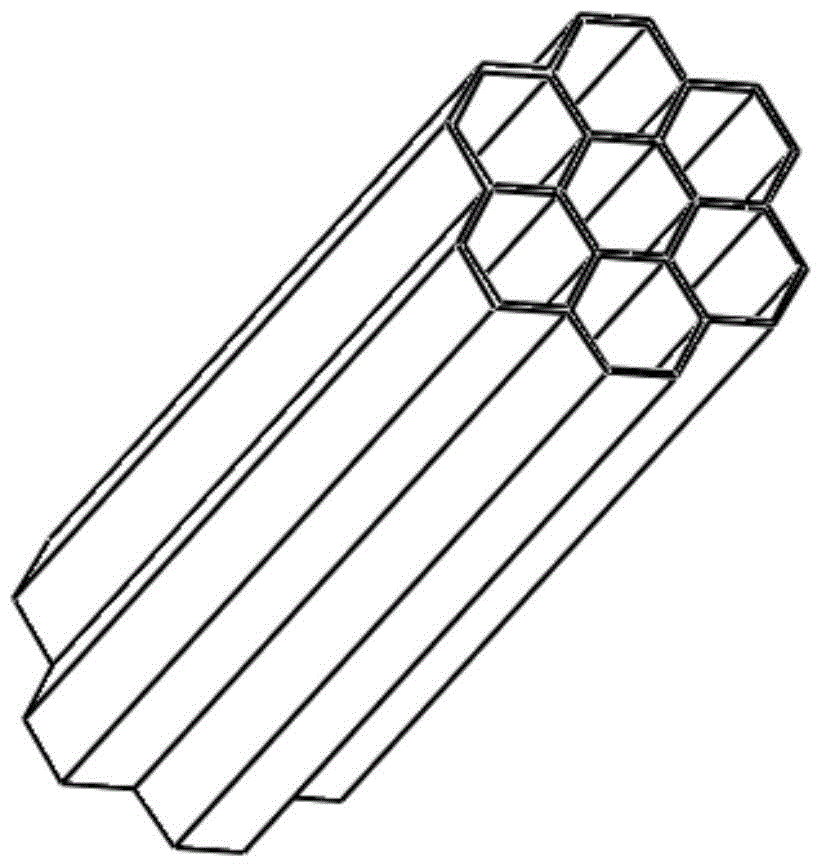

[0034] In this embodiment, a high-strength steel transmission tower with a honeycomb structure is taken as an example, such as Figure 1 to Figure 5 As shown, the high-strength steel transmission tower with honeycomb structure provided by the embodiment of the present invention includes: tower body 1, main pipe 2, honeycomb structure 3, reinforced concrete foundation 4, cement 5, flange 6, cross arm 7, connecting node 8, Ground wire support 9, connecting plate 10, reinforcing plate 11, connecting screw hole 12; honeycomb structure 3 formed by six hollow regular hexagonal bodies surrounding one hollow regular hexagonal body is bonded in the main pipe 2 through an adhesive layer to form the tower body 1 After the tower body 1 is connected by the flange 6, it is vertically installed in the reinforced concrete foundation 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com