Screw-type air compressor

An air compressor and screw type technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of increasing indoor temperature and troubles in the working environment of operators, so as to ensure the working environment and avoid the effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

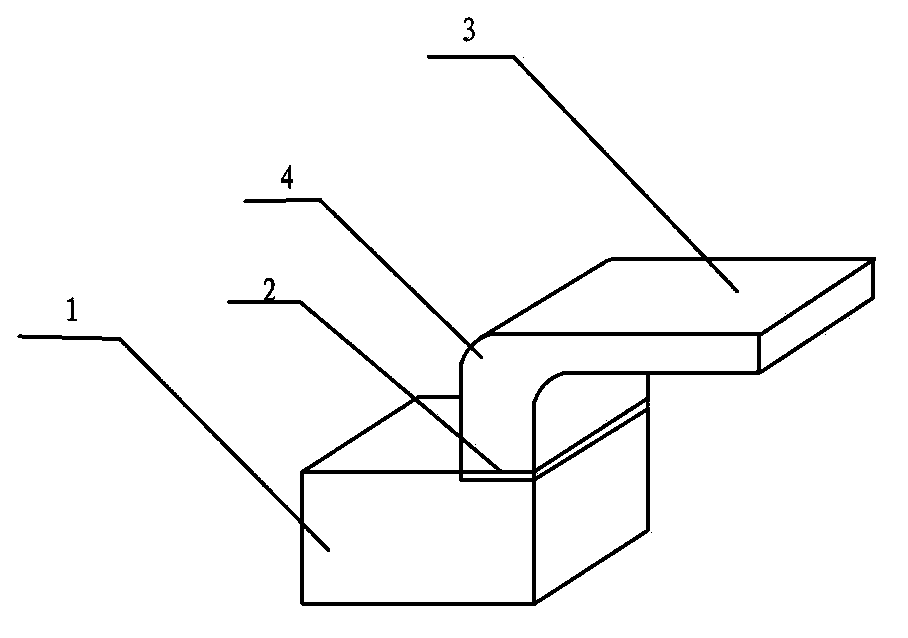

[0012] see figure 1 As shown, the screw air compressor includes a body 1, and a heat dissipation area 2 is arranged above the body 1, and the heat dissipation area 2 is composed of a plurality of heat dissipation holes arranged neatly. The upper cover of the heat dissipation area is provided with a diversion shell 3, which is set in an inverted L shape, and its 4 corners are arc-shaped and smoothly connected. The increase ensures the working environment of the operator.

[0013] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. All modifications and equivalent transformations made within the spirit of the present invention shall fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com