Honing device for eliminating steam turbine rotor journal runout out-of-tolerance

A steam turbine rotor and journal technology, applied in the field of machinery, to achieve the effects of avoiding cost and cycle, simple structure, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

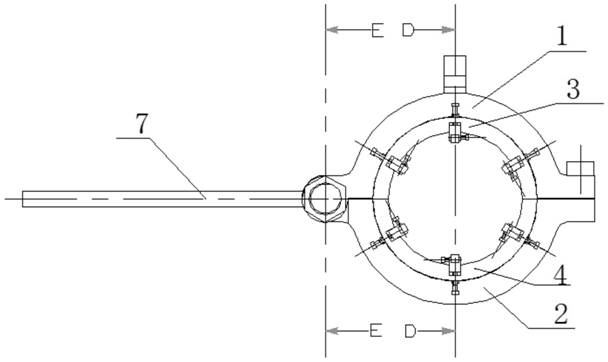

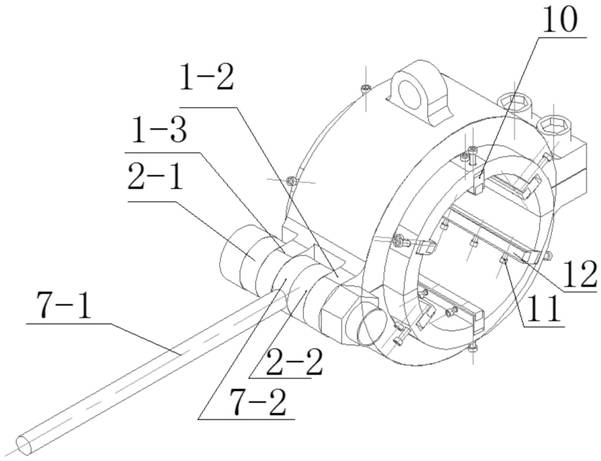

[0026] Specific implementation mode one: combine Figure 1 to Figure 7 This embodiment is described. A honing device for eliminating runout of a steam turbine rotor journal described in this embodiment includes a housing, a bushing, a longitudinal rod 7 and a plurality of clamping block assemblies, and the housing is sleeved on the bushing. A plurality of clamping block assemblies are installed on the inner wall of the bush along the circumferential direction, and the longitudinal rod 7 is rotatably connected with the outer wall of the housing.

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 7 Describe this embodiment, the casing described in this embodiment is the torus that is made up of upper half casing 1 and lower half casing 2, and one end of upper half casing 1 is connected with the right end of lower half casing 2 by bolt, The other end of the upper half-shell 1 is connected to the left end of the lower half-shell 2 through a screw, and one end of the longitudinal rod 7 is rotatably connected to the screw 5 . Longitudinal bar 7 is made up of cylindrical body 7-1 and tubular body 7-2.

[0028] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

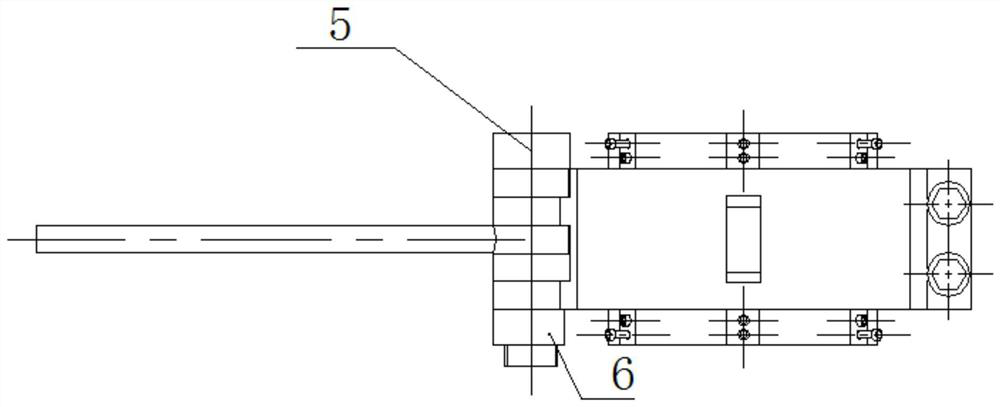

[0029] Specific implementation mode three: combination Image 6 with Figure 7 To illustrate this embodiment, the left end of the upper half shell 1 in this embodiment is provided with a first tubular handle 1-2 and a second tubular handle 1-3; the left end of the lower half shell 2 is provided with a third tubular handle 2- 1 and the fourth tubular handle 2-2, one end of the screw pin 5 passes through the third tubular handle 2-1, the second tubular handle 1-3, the tubular body 7-2 of the longitudinal rod 7, the fourth tubular handle 2- After 2 and the first tubular handle 1-2, with nut 6, tighten the stop above and connect as the door hinge connection structure.

[0030] The other components are the same as those in Embodiment 1 or 2 in terms of connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com