Dynamic gear clearance eliminating device

A dynamic and anti-backlash technology, applied in hoisting devices, portable lifting devices, belts/chains/gears, etc., can solve the problems of inability to ensure the synchronization of helical gears, complex structural design, etc., to reduce impulse and Vibration, simple structure design, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

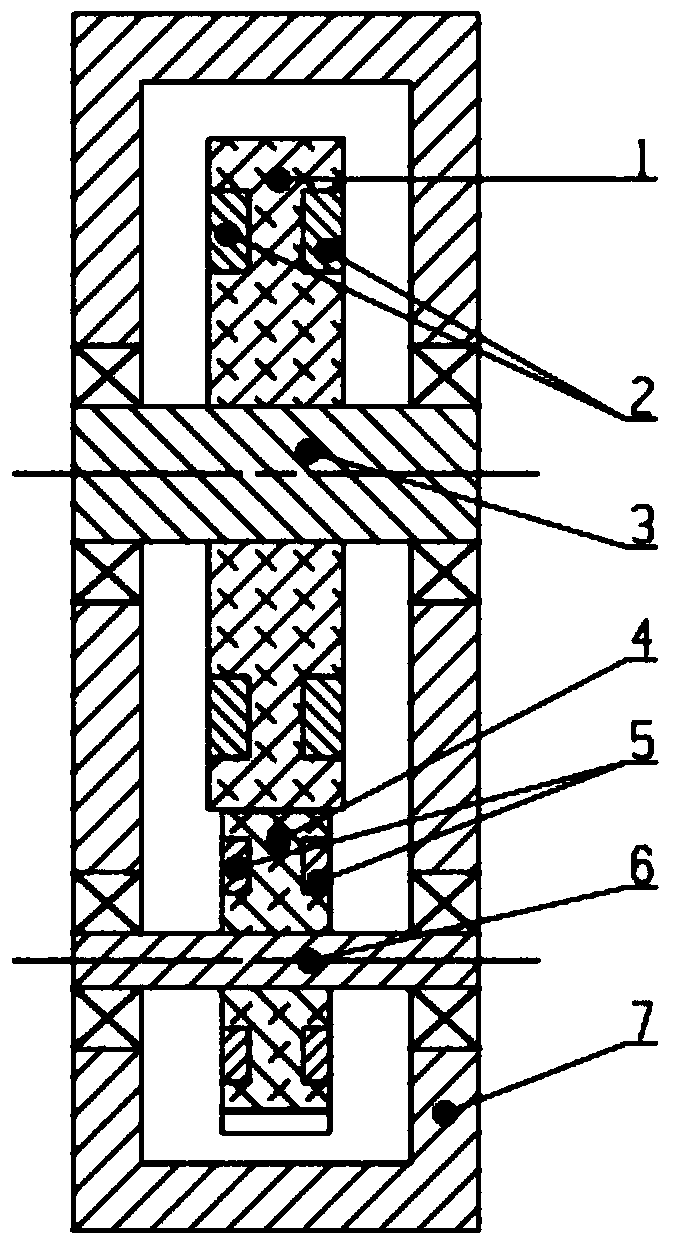

[0017] Such as figure 1 As shown, a gear dynamic anti-backlash device, the device includes a driven gear 1, a large magnet 2, a driven shaft 3, a driving gear 4, a small magnet 5, a driving shaft 6 and a base 7, and the large magnet 2 Embedded on the driven gear 1, the driven gear 1 is connected with the driven shaft 3, the small magnet 5 is embedded on the driving gear 4, the driving gear 4 is connected with the driving shaft 6, and the driven shaft 3 and the driving shaft 6 are both By the bearing being arranged on the base 7, the hole distance of the two bearing seats on the base 7 can guarantee a certain positioning accuracy during processing, and the bearing and the base hole, the shaft and the bearing adopt a clearance fit. The outer ring magnetic pole of big magnet 2 and little magnet 5 is opposite, promptly big magnet 2 adopts the magnetic pole direction of outer ring N pole (or S pole), then little magnet adopts the magnetic pole direction of outer ring S pole (or N p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com