Double-cavity flameless burner

A flameless combustion, double concave cavity technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of the complex structure of the flameless combustion chamber, no double concave cavity structure trapped vortex flameless combustion, etc. The effect of uniform temperature distribution and reduction of pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

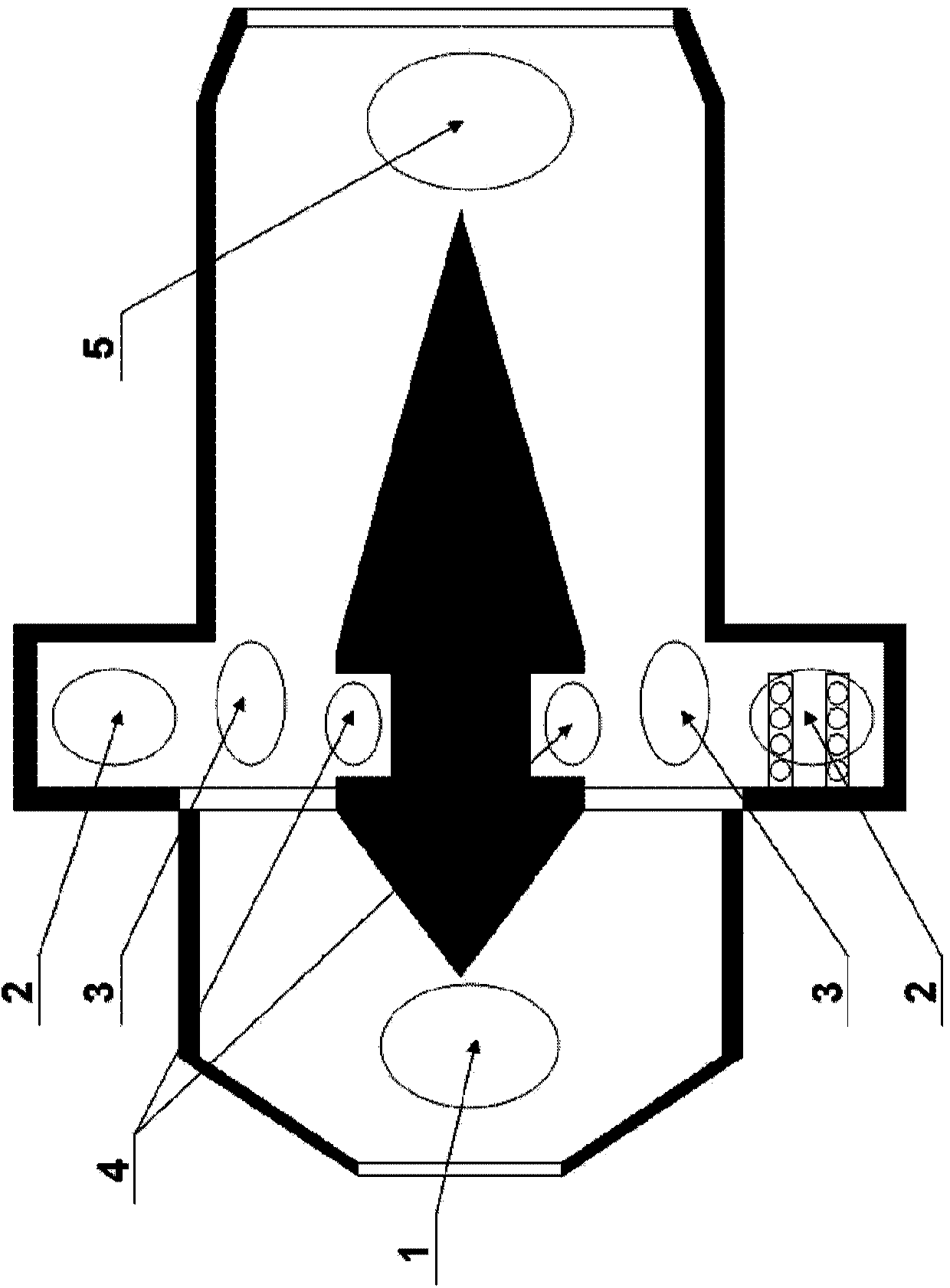

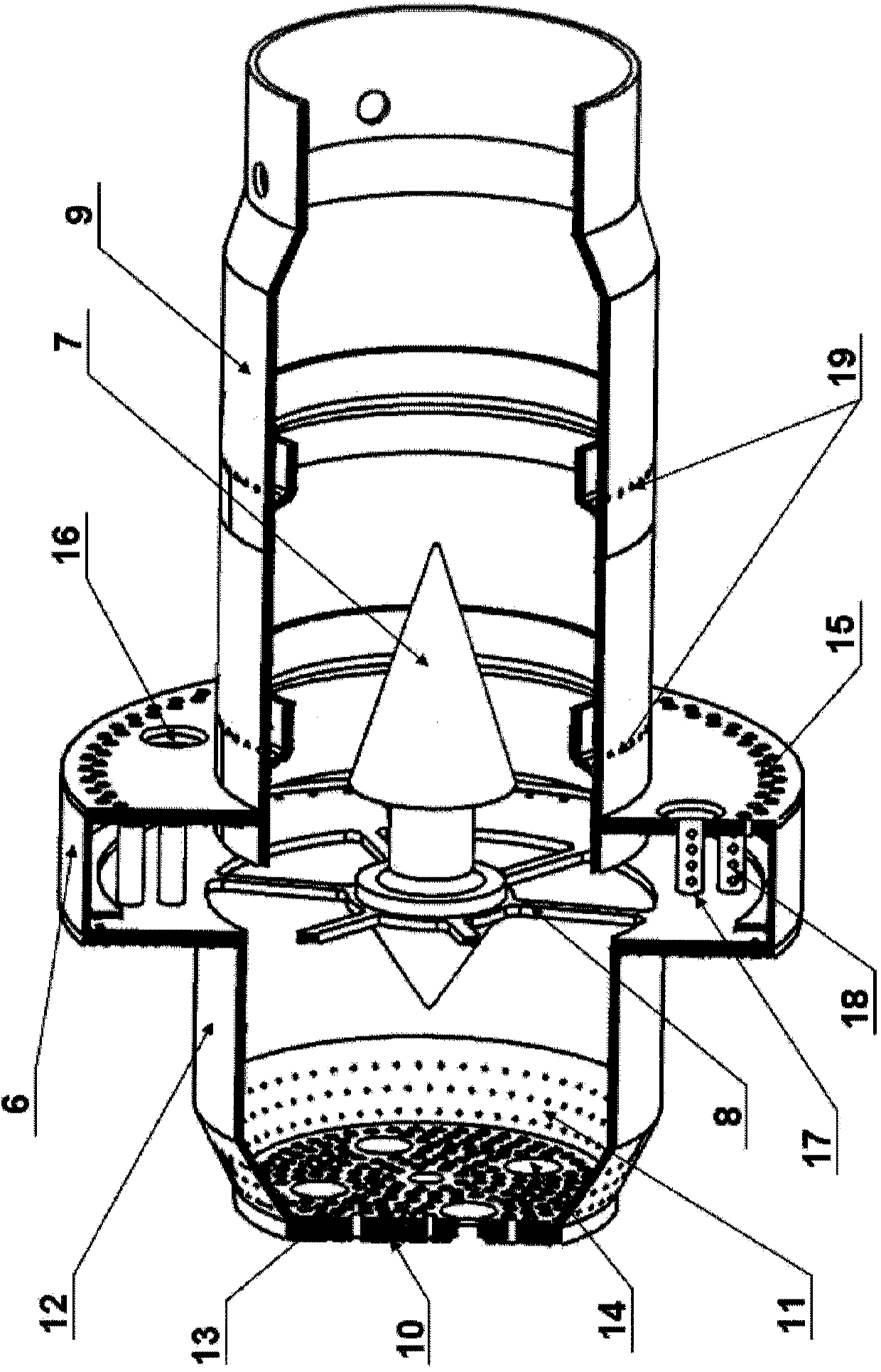

[0025] The invention combines the advantages of flameless combustion and concave cavity vortex combustion, and discloses a double concave cavity vortex flameless burner suitable for gas turbines.

[0026] The double-cavity flameless burner of the present invention includes two areas, the main cavity and the secondary cavity. A small amount of air and fuel are sprayed into the main cavity to generate high-temperature smoke. After the high-temperature smoke flows out of the main cavity, it enters the mixed Under the disturbance of the sub-cavity area, the mixing zone is mixed with the fuel-air mixture from the head zone to achieve flameless combustion conditions, and forms flameless combustion in the downstream to achieve the purpose of reducing pollutant emissions.

[0027] The main difficulty of the present invention for the design of the known flameless burner is to realize the rapid mixing of high-temperature flue gas and fresh fuel-air mixture, so as to achieve the condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap