A medium-high temperature cavity type heat collecting tube used in a trough heat collecting system

A medium-high temperature, cavity-type technology, applied in the field of solar collector tubes, can solve the problems of lowering the working efficiency of the trough solar system, system stability, complicated process of the collector tube, high cost, etc., to achieve mass production and good heat transfer effect , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

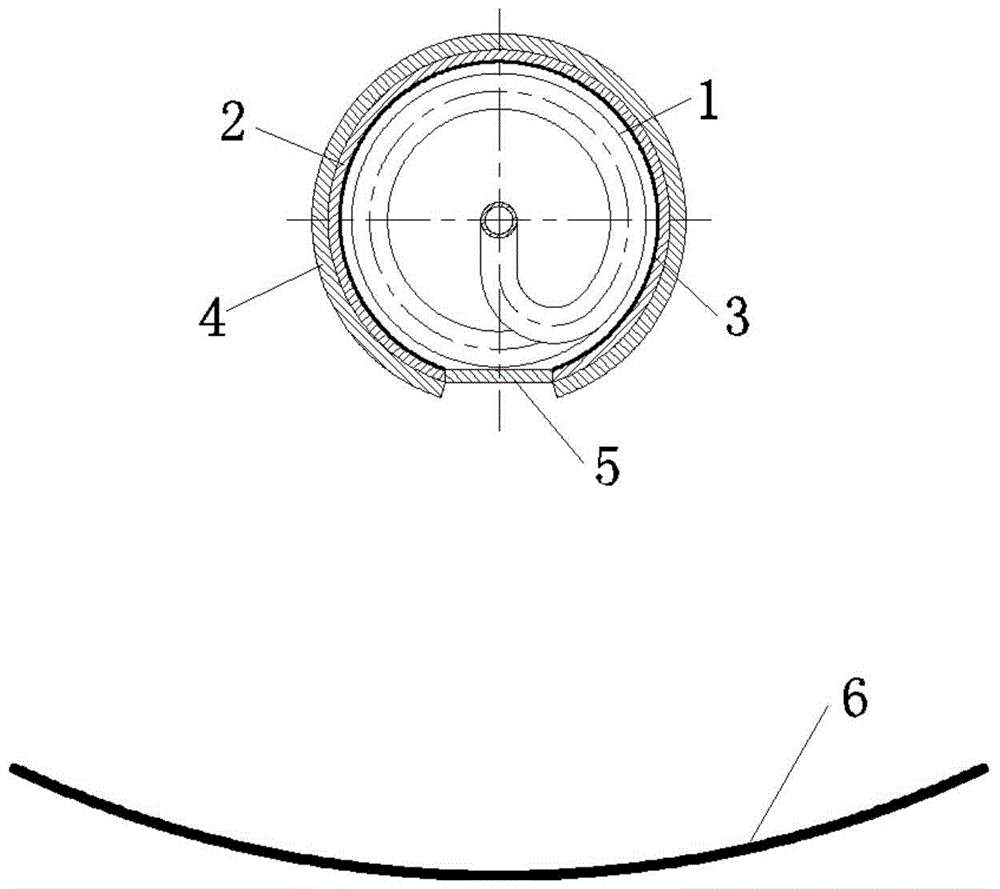

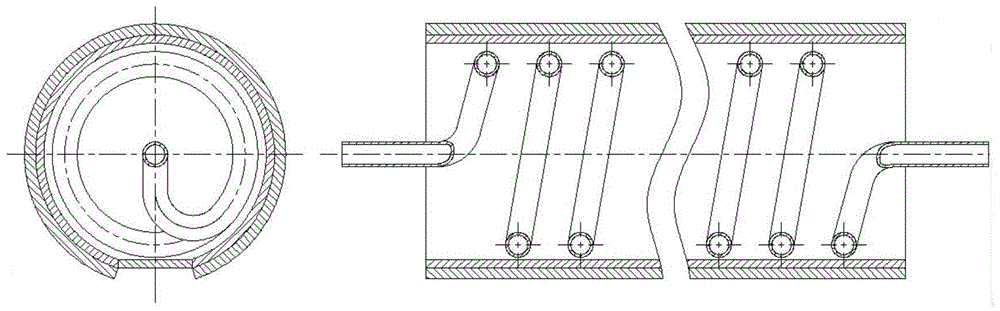

[0028] The middle and high temperature cavity type heat collecting tube used in the trough heat collecting system of the present invention, such as figure 1 and figure 2 As shown, it includes a spiral metal absorption tube 1, a circular metal cavity 2, a reflective film 3, an insulating layer 4 and ultra-clear glass 5.

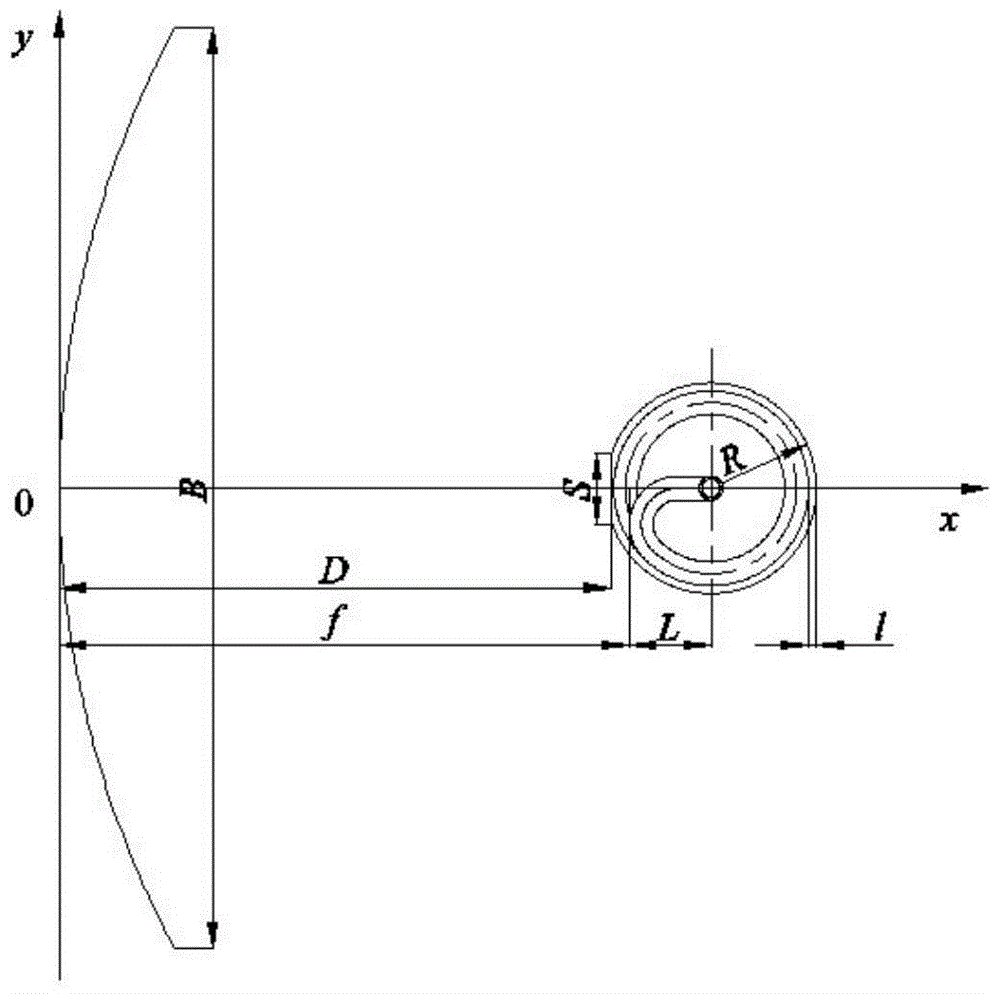

[0029] Wherein the circular metal cavity 2 is not closed, and a certain opening is left as a light entrance, and the light entrance is sealed with ultra-clear glass 5 . The midpoint of the light incident port, the focal point of the concentrating parabolic mirror and the center of the circular metal cavity are on a straight line. The concentrating parabolic mirror is used to focus the parallel sun rays, so that the rays enter the circular metal cavity through the light entrance. The spiral metal absorption tube 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com