Sieve plate-free fluidizing chlorination furnace

A technology of fluidized chlorination furnace without sieve plate, which is applied in the direction of titanium halide, etc., can solve the problems of destroying the normal production of the upper slag discharge chlorination furnace, achieve the effect of prolonging the continuous operation time, expanding the scope of application of raw materials, and overcoming harsh requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

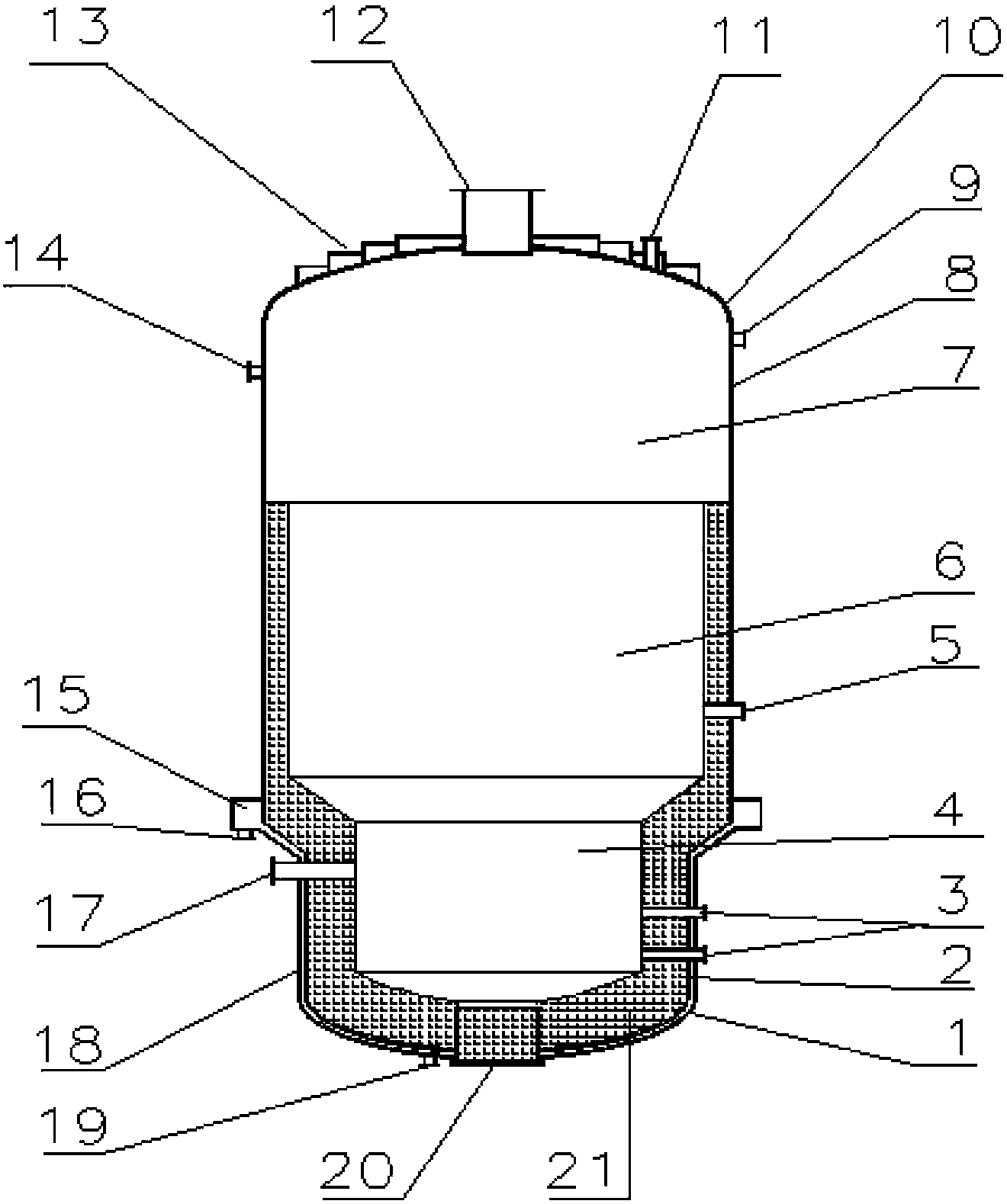

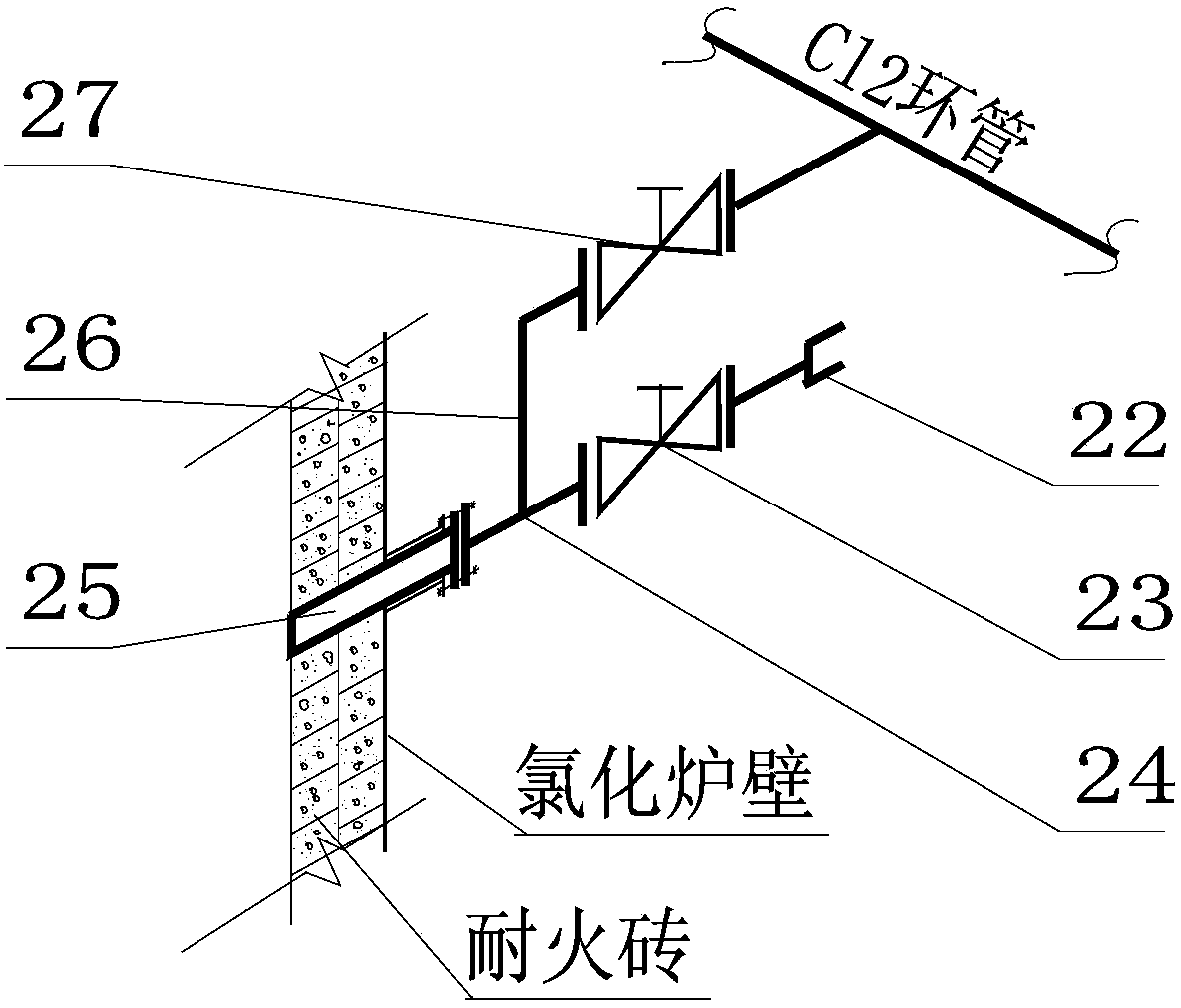

[0018] Such as figure 1 , figure 2 shown. A boiling chlorination furnace without a sieve plate, comprising upper and lower cylinders 8 and 2, the lower cylinder 2 is connected to the bottom of the upper cylinder 8 through a hollow tapered part, and an upper cylinder with an inner cavity is installed on the top of the upper cylinder 8 Head 10, lower head 1 with an inner cavity is installed at the bottom of the lower cylinder 2, wherein the inner cavity of the lower head 1 and the inner cavity of the lower cylinder 2 constitute the chlorine gas inlet chamber 4, the inner cavity of the tapered part, and the upper cylinder 8 The middle and lower part of the inner cavity constitutes the material boiling section 6, the inner cavity of the upper head 10, and the upper part of the inner cavity of the upper cylinder body 8 constitute the gas-solid separation section 7, the chlorine gas inlet chamber 4 is lined with refractory bricks 21, and the chlorine gas inlet chamber 4 is covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com