Vanadium removing system and method for crude titanium tetrachloride refining

A crude titanium tetrachloride, titanium tetrachloride technology, applied in the direction of titanium halide and other directions, can solve the problems of paralysis of key equipment, affecting heat transfer of equipment, scarring of equipment pipelines, etc., achieving long continuous operation time and fast vanadium removal. , high vanadium removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the system and method for refining vanadium removal from crude titanium tetrachloride according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

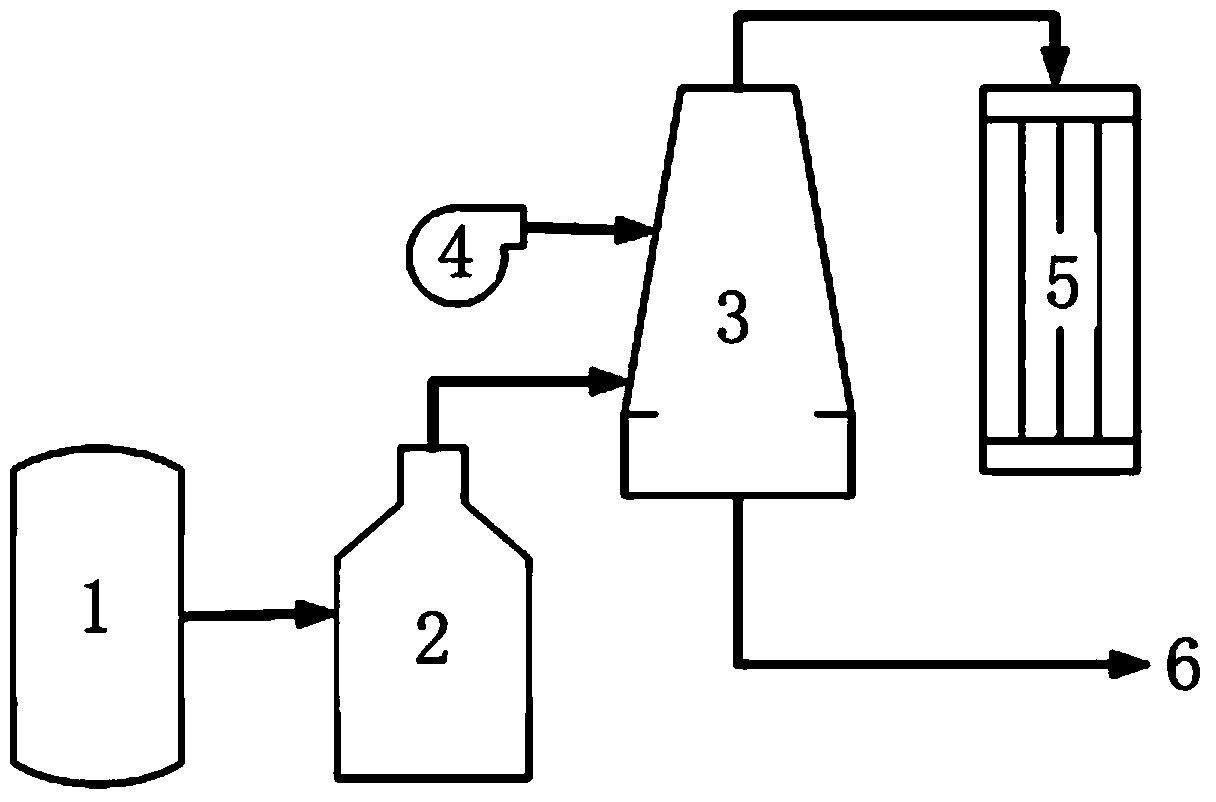

[0018] figure 1 It is a schematic diagram of a vanadium removal system for refining crude titanium tetrachloride according to an exemplary embodiment of the present invention. like figure 1 As shown, the crude titanium tetrachloride refining vanadium removal system according to an exemplary embodiment of the present invention includes: crude TiCl 4 Storage tank storage tank 1, TiCl 4 Steam generating device 2 , refining vanadium removal tower 3 , organic vanadium removal reagent adding device 4 and condenser 5 .

[0019] Wherein, the crude titanium tetrachloride storage tank 1 is connected with the chlorination system, and the crude TiCl produced by the chlorination system 4 into TiCl 4 Tank 1 cache.

[0020] Refining vanadium remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com