Improvement method for removing impurities in titanium tetrachloride by virtue of aluminum powder

A technology of titanium tetrachloride and titanium trichloride, applied in the directions of titanium tetrachloride, titanium halide, etc., can solve the problems of reducing the recovery rate of titanium tetrachloride, large amount of vanadium-removing residue liquid, and high energy consumption of the residue liquid, Achieve the effect of reducing the amount of vanadium removal residue liquid, less aluminum powder consumption, and faster vanadium removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

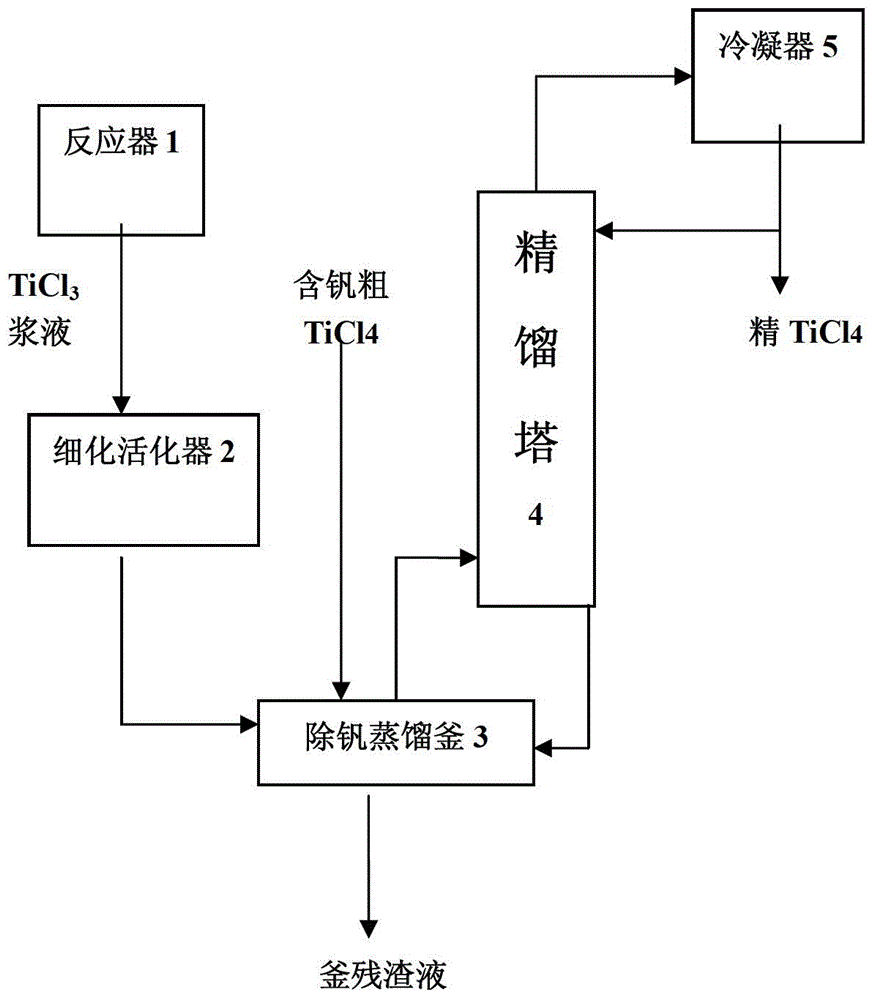

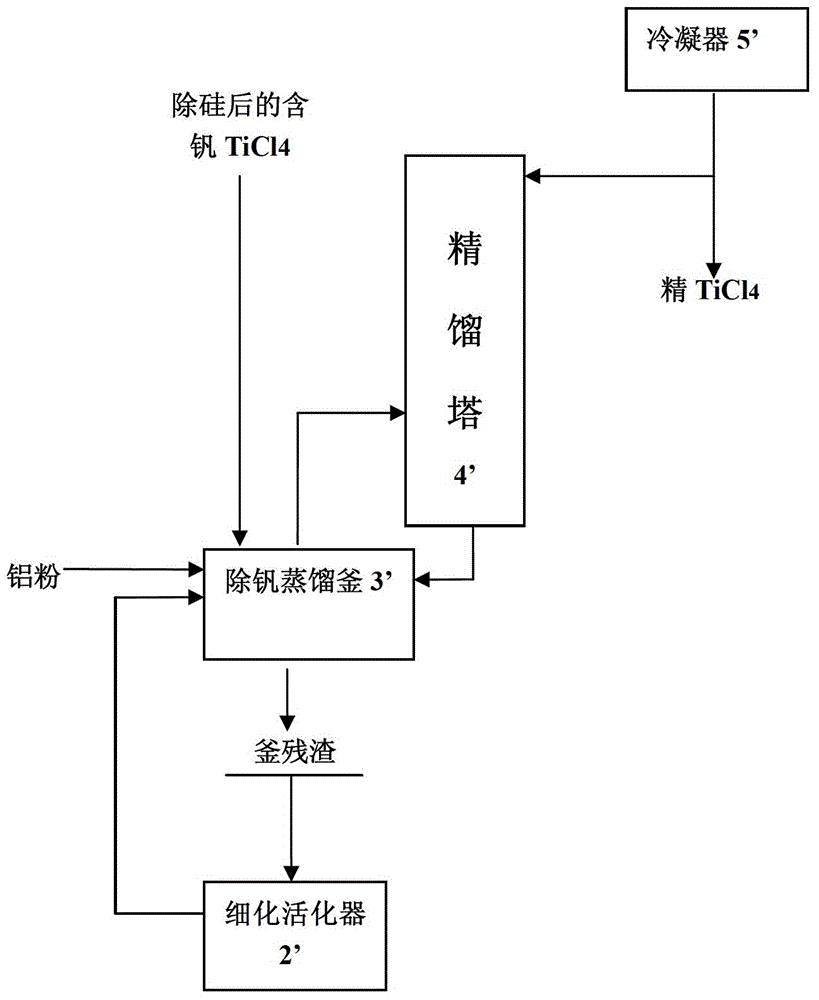

Method used

Image

Examples

Embodiment 1

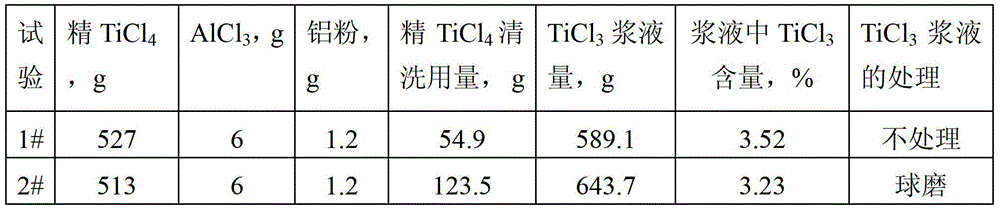

[0029] Embodiment 1: Preparation of TiCl 3 slurry test

[0030] Install a reflux condenser on a 500ml flask, add raw materials in the flask, including refined TiCl 4 , AlCl 3 and aluminum powder, heat the flask on an electric furnace to make the reactant mixture boil, the evaporating product is condensed in the condenser and refluxed into the flask, when the reactant boils for a period of time, purple-red TiCl appears 3 , indicating that the reaction has started, and then maintain the boiling state for a certain period of time to complete the reaction. After the reaction is completed, it is cooled to TiCl 3 Slurry, with refined TiCl 4 Cleaning is transferred to containers and metered.

[0031] Prepare two TiCl according to the raw material composition listed in Table 1 3 Slurry sample, in which 1#TiCl 3 Slurry without any treatment; 2#TiCl 3 The slurry was prepared by ball milling in a ball mill tank for 4 hours at a milling speed of 60 rpm. The test results are liste...

Embodiment 2

[0040] Embodiment 2: TiCl treated by ball milling 3 Vanadium removal test of slurry

[0041] Ball-milled TiCl 3 The operating process of the vanadium removal test of the slurry is the same as that of Comparative Example 1, except that the 2# TiCl prepared in Example 1 is processed through ball milling 3 Slurry replaces untreated 1# TiCl 3 slurry. Ball-milled TiCl 3 The vanadium removal test results of the slurry are listed in Table 3.

[0042] Table 3 TiCl treated by ball milling 3 Slurry vanadium removal test results

[0043]

Embodiment 3

[0049] Embodiment 3: the vanadium removal test of the still residue liquid of ball milling treatment

[0050] The operation process of removing vanadium is the same as that of Comparative Example 2, and the raw material crude TiCl 4 (VOCl 3 Content 0.21%) was added and ball milled in a ball mill tank for 4 hours at a ball milling speed of 60 rpm, and the activated still residue liquid was used for vanadium removal. The test results are listed in Table 5.

[0051] Table 5 Test results of vanadium removal in industrial production kettle residue liquid by ball milling

[0052]

[0053] In addition to ball milling, other mechanical pulverizing and grinding methods can also be used in the refinement and activation treatment of the present invention, such as rod mills and sand mills, or ultrasonic pulverization methods, all of which can achieve the same effect as ball milling.

[0054] It can be seen from comparative example 1 and embodiment 2 that the TiCl treated by ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com