Assembly line for automatically detecting quality of gray cloth of seamless underwear

A seamless underwear, automatic detection technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of missed detection and false detection, slow detection speed, easy fatigue of the eyes, etc., to achieve high efficiency, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

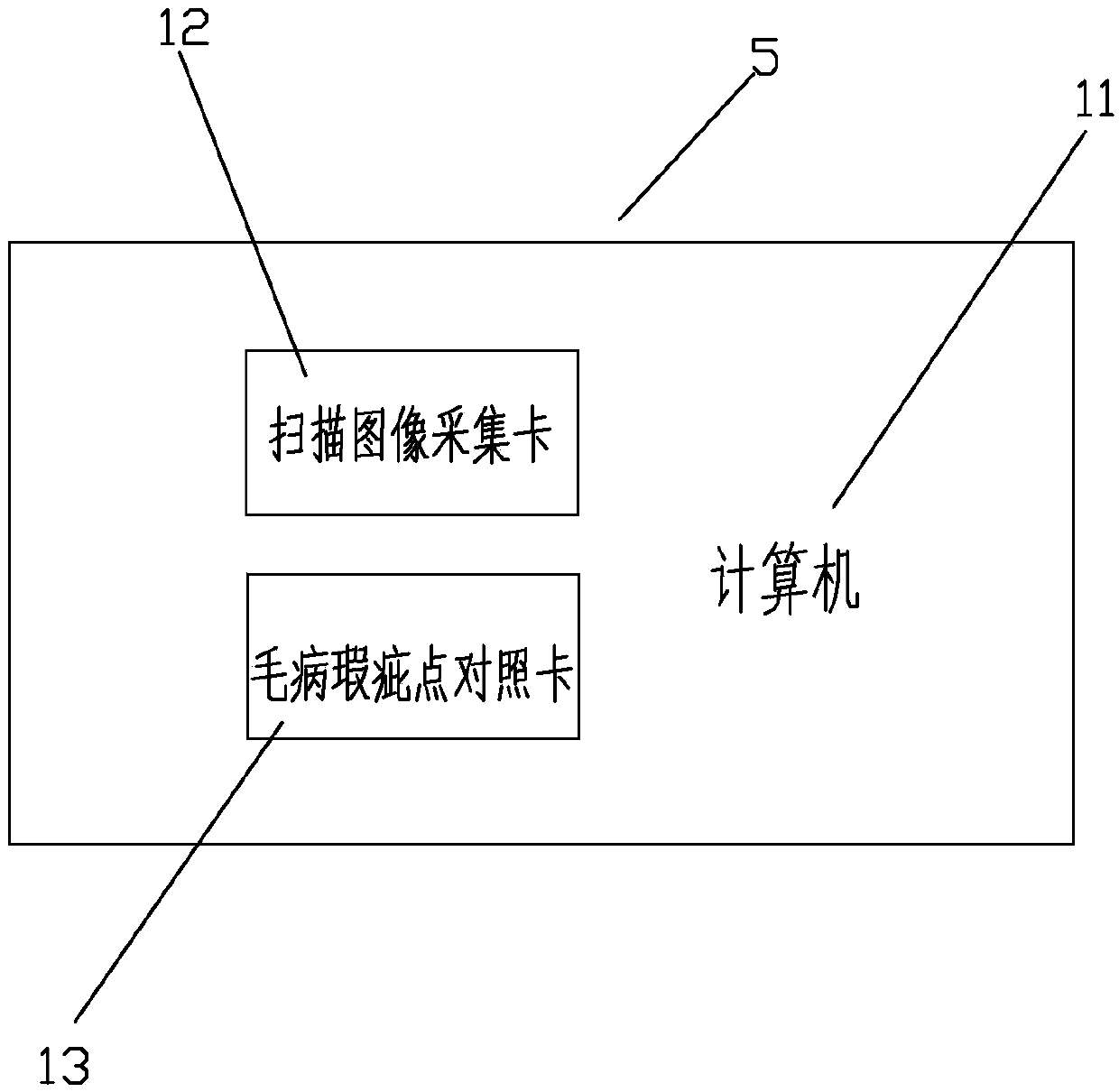

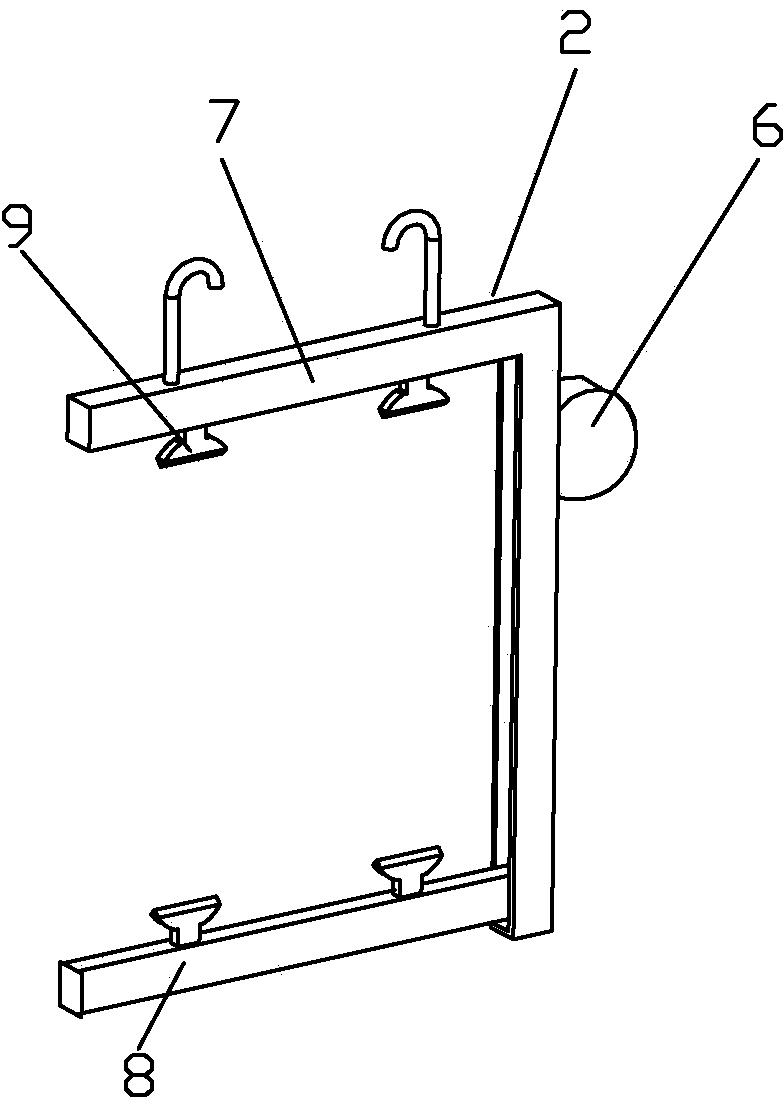

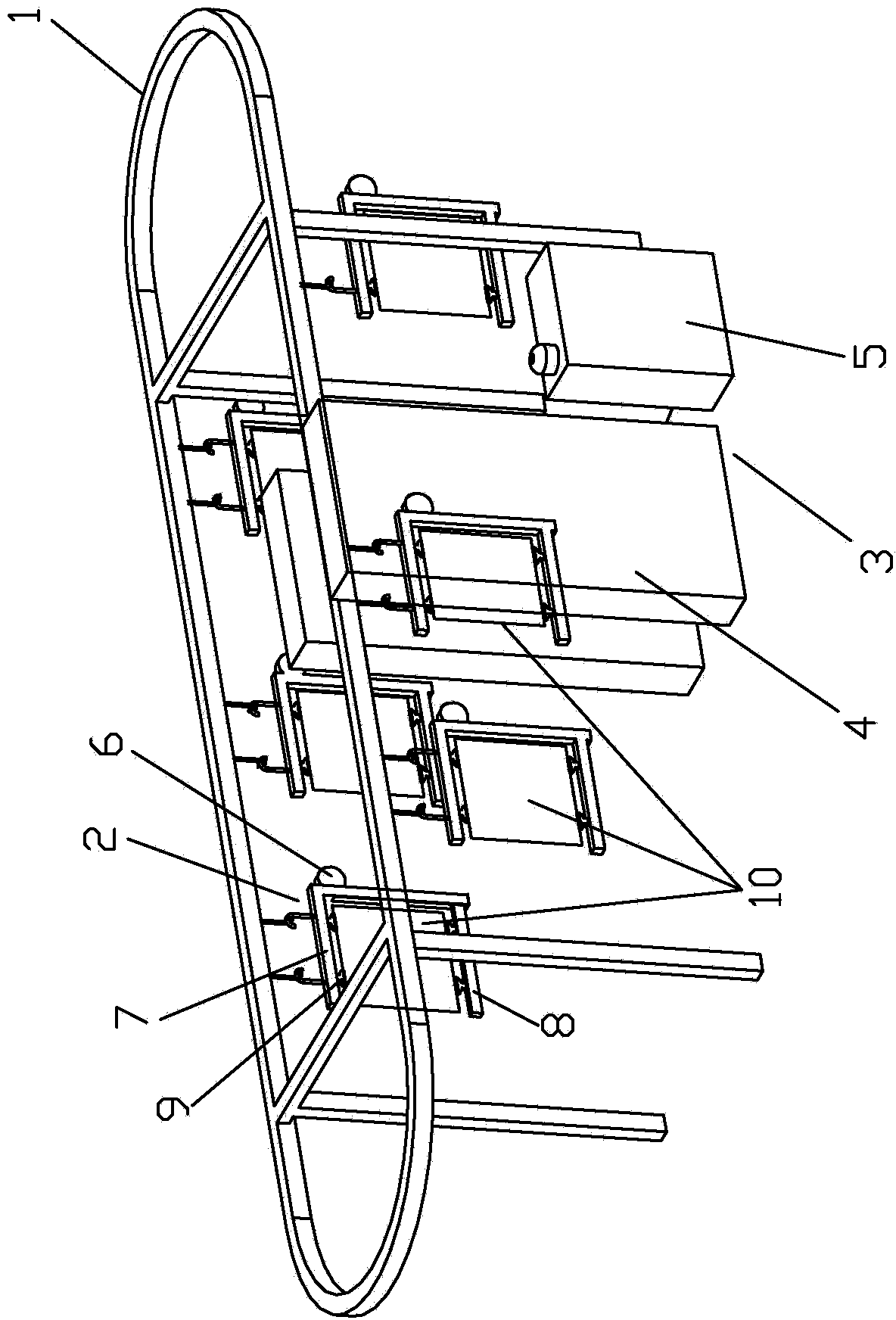

[0015] The following is figure 1 The present invention is further described in the embodiment represented by -3, which includes an annular assembly line 1 for conveying the seamless underwear gray cloth 10, a device for hanging the seamless underwear embryonic cloth 10 that can be freely removed on the annular assembly line 1 The clamping frame 2, and the seamless underwear gray cloth quality detection device 3 arranged on both sides of the circular assembly line 1, the seamless underwear gray cloth quality detection device 3 is composed of the seamless underwear gray cloth image scanning device 4, and the The scanning image information processing device 5 connected to the sewing underwear gray cloth image device 4 and the wireless alarm device 6 connected with the scanning image information processing device 5 are composed; the scanning image information processing device 5 includes a computer with image contrast processing software 11. The scanning image acquisition card 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com