High-voltage electric field measuring method and device based on non-vertical fiber bragg gratings

A fiber grating and high-voltage electric field technology, applied in the direction of electrostatic field measurement, voltage/current isolation, etc., can solve problems such as complex structure, difficult assembly and portability, and difficult optical path adjustment, so as to improve measurement accuracy, easy to operate and carry, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

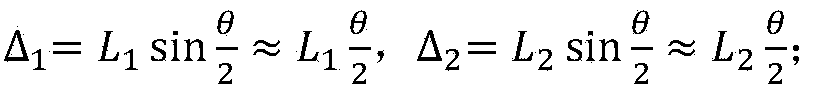

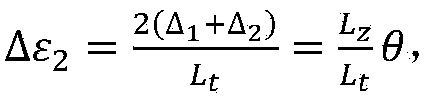

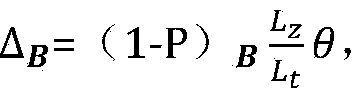

[0031] Such as figure 1 , figure 2 and Figure 5 As shown, the electric field demodulation system of this embodiment includes: an electric field sensing device, a broadband light source 6 connected in series through an optical fiber 10, two serially connected two-circulators 7, 8, and a photodetector 9, wherein: the electric field sensing device includes a composite voltage The electrical material 1 / 2 and the two fiber gratings 3, 4 parallel to it, and the two circulators 7, 8 are respectively connected to one end of the two fiber gratings 3, 4 in the electric field induction device.

[0032] Such as figure 1 As shown, the two fiber gratings in the bonded electric field sensing device are directly bonded to the upper and lower surfaces of the composite piezoelectric material in parallel, or as shown in figure 2 As shown, it is a cantilever type electric field induction device, in which two fiber gratings 3 and 4 are arranged in parallel on both sides of the composite piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com