An assembly process of a relay

An assembly process and relay technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of reduced production efficiency, reduced safety factor, increased cost, etc., to improve labor productivity, improve safety, and fast curing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

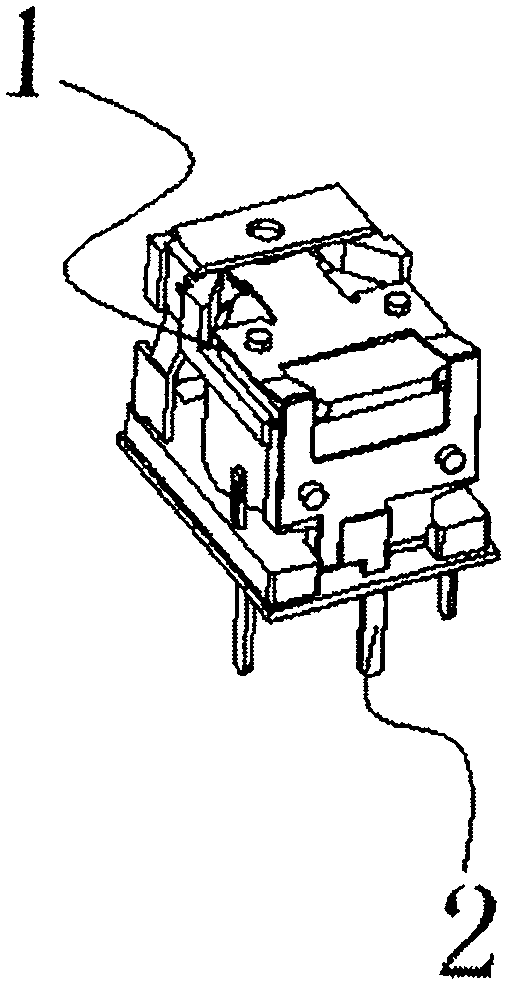

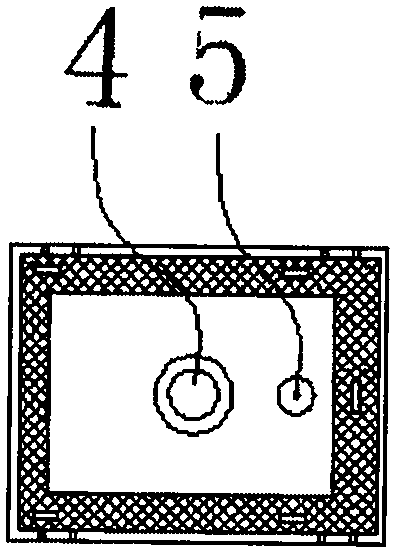

[0033] Such as Figure 1~6 As shown, a relay includes a main frame 1 and a cover 3, electrical components are installed on the main frame 1, the cover 3 is sealed on the main frame 1, the main frame 1 includes a bottom plate, and a sealing is arranged in the middle of the bottom plate Hole 4, a dispensing hole 5 is arranged next to the sealing hole 4, the sealing hole 4 and the dispensing hole 5 communicate with the inside of the main frame 1, and the sealing hole 4 is deliberately left when the relay is used to fix the iron core during the assembly process Therefore, the diameter of the sealing hole 4 is often 3 to 4mm. Therefore, if the sealing hole 4 is sealed with an expensive glue with a fast curing speed, the cost will be greatly increased, and only a low-priced two-component glue can be used to remove it. Sealing, so a dispensing hole 5 is opened next to the sealing hole 4. The dispensing hole 5 is a circular table. A syringe is required for dispensing, so the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com