Twisted waveguide

A technology of waveguide and twisting, applied in the field of waveguide adapters, to achieve the effects of avoiding assembly errors, simple structure, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

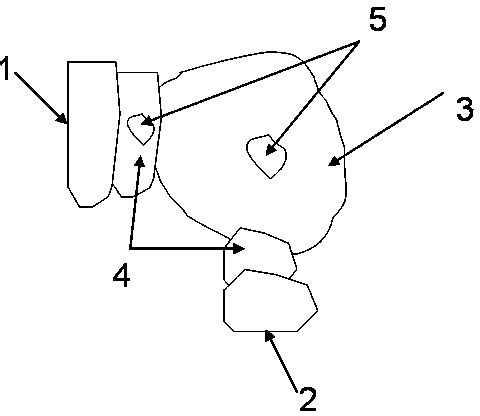

[0025] Such as figure 1 As shown, a twisted waveguide includes a coupling area 3 and two signal channels A and B connected to the coupling area 3, the signal channel A is provided with a port A1, the signal channel B is provided with a port B2, and the port A1 The normal direction at the center of and the normal direction at the center of port B2 form an included angle X, the value of X is 88 degrees, and the maximum size of port A1 on the horizontal plane is greater than the maximum size of port B2 on the horizontal plane. Here, the cross-sectional shape of the horizontal plane of the coupling region 3 is irregular.

[0026] A matching transition section 4 is provided between the port A1 in the signal channel A and the coupling area 3, and a matching transition section is provided between the port B2 in the signal channel B and the coupling area 3 paragraph 4. Here, the cross-sectional shape of the horizontal plane of the matching transition section 4 is irregular.

[002...

Embodiment 2

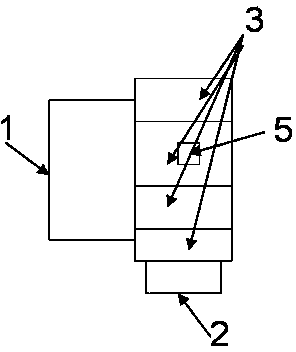

[0034] Such as figure 2 with 3 shown. Compared with Embodiment 1, the only difference is that the cross-sectional shape of the coupling region 3 on the horizontal plane is rectangular. At the same time, no matching transition section 4 and metal body 5 located thereon are provided. At the same time, the maximum depth of the coupling region 3 is more than 15% greater than the minimum depth, and the depth of the coupling region 3 gradually increases along the normal direction at the center of the port B2.

Embodiment 3

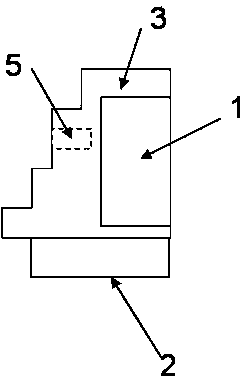

[0036] Such as Figure 4 shown. Compared with Embodiment 2, the only difference is that a matching transition section 4 is provided on the signal channel A and signal channel B respectively, and a metal body 5 is provided on the bottom of the matching transition section 4 on the signal channel A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com