An Image Quantitative Detection Method for Carrot Defects

A carrot defect, image quantification technology, applied in the field of detection of agricultural product appearance quality defects, can solve problems such as application limitations, and achieve the effects of improving production efficiency, quantitative detection objective, and customer service subjectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

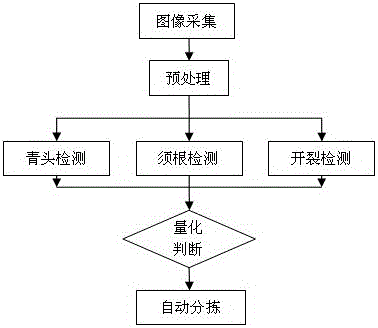

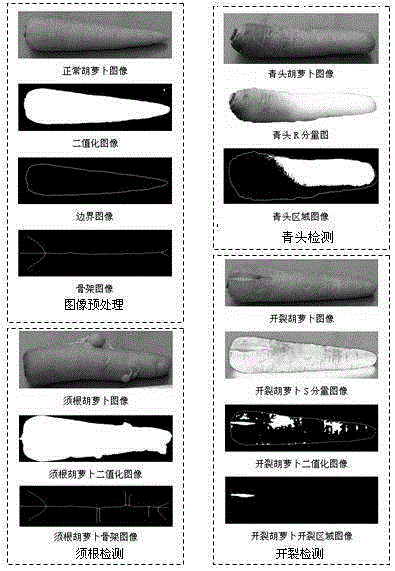

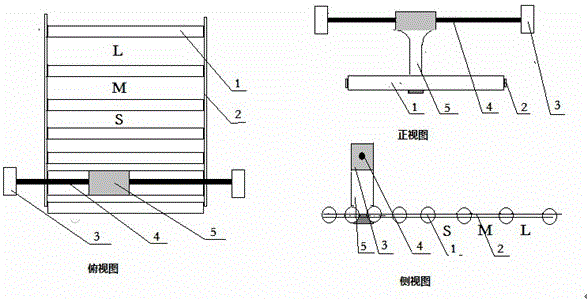

[0041] Embodiment 1, a method for quantitatively detecting carrot greenheads, fibrous roots and cracked images disclosed in the present invention, the method includes an image acquisition and preprocessing unit, a carrot greenhead quantitative detection unit, fibrous roots quantitative detection unit, and cracked images Quantitative detection unit and sorting device.

[0042] figure 1 Schematically shows the defect monitoring process of the present invention, first put the carrots flat on the green sorting device, use a digital camera to take a color image of the carrots, send the images to the computer for the following processing; convert the above images into RGB and HSV components Image, extract the H component image, use this component to binarize to obtain the binarized image BW, and perform edge detection, and calculate the carrot area Area1 on the binarized image. Finally, the captured image is transmitted to the computer for use in measuring characteristics. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com