A profiling device for friction wheel arc surface and using method thereof

A technology of circular arc surface and mold-based processing, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of difficulty in promotion and application, low practicability, etc., and achieves reduced labor intensity of workers, fast operation, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

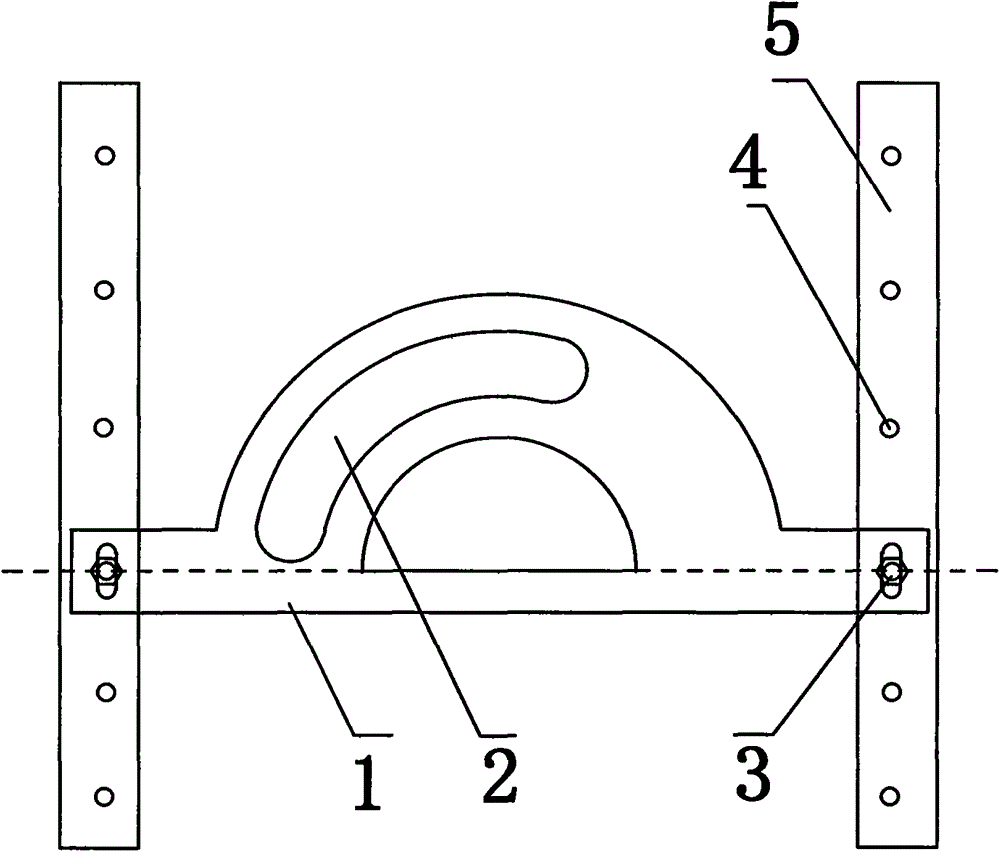

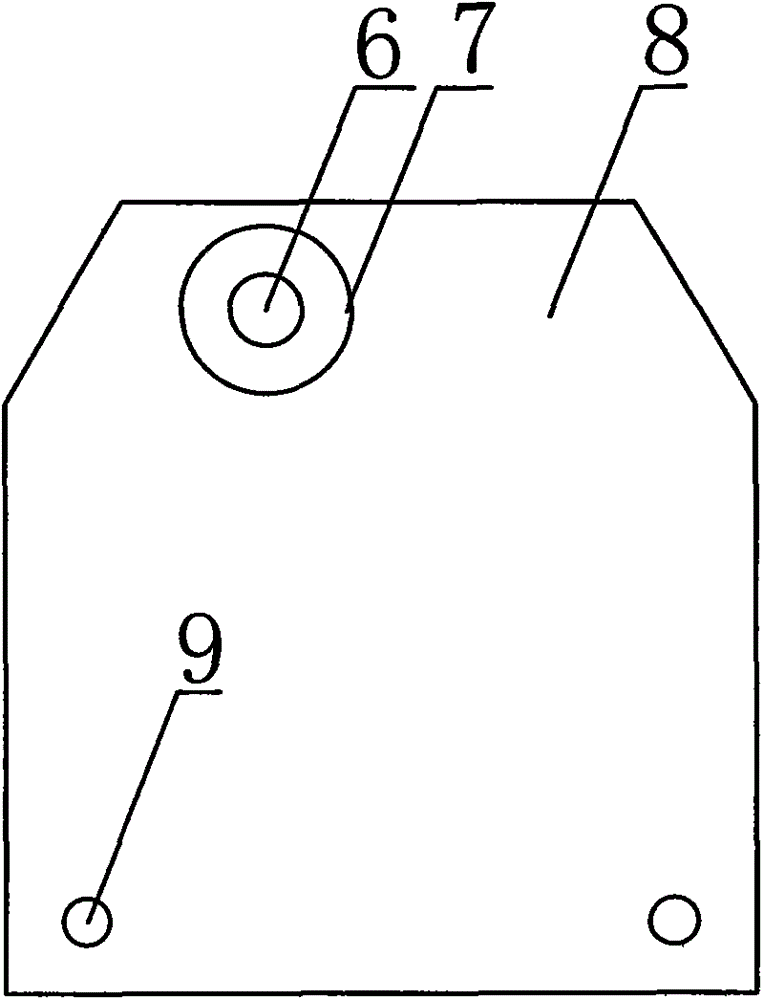

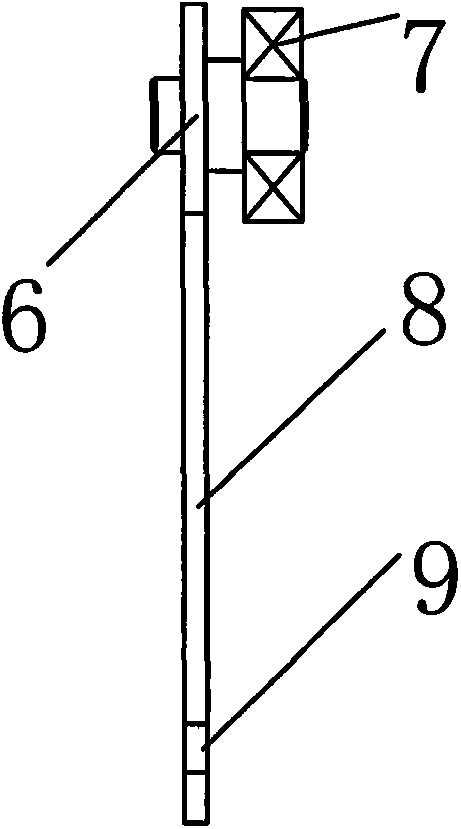

[0049] As shown in the figure, a profiling device for a friction wheel arc surface is composed of: a template 1, a roller arc groove 2, a template bolt 3, a template screw hole 4, a bridge pressure plate 5, a roller shaft 6, and a roller 7 , middle support connecting plate 8, connecting plate screw hole 9, large supporting plate 10, large supporting plate guide rail 11, guide rail pad iron 12, longitudinal guide rail 13, small supporting plate guide rail 14, small supporting plate frame 15 constitute; It is characterized in that: A guide rail pad 12 is arranged between the two longitudinal guide rails 13 of the lathe, and a bridge pressure plate 5 is arranged above the guide rail pad iron 12, a large pallet guide rail 11 is provided at both ends of the bridge pressure plate 5, and a large pallet 10 is arranged above the large pallet guide rail 11. A small pallet guide rail 14 is arranged on one side of the large pallet 10, and a small pallet frame 15 is arranged above the small...

Embodiment 2

[0055] As shown in the figure, a method of using a profiling device for a friction wheel arc surface, the specific process steps are as follows:

[0056] First of all, according to the technical parameter requirements of the drawing, and according to the curvature radius of the friction wheel arc surface of the workpiece to be processed, a template 1 with the same curvature radius as the roller arc groove 2 is made; the curvature radius of the friction wheel arc surface is designed to be R130mm- R190mm, make the center line of the roller arc groove 2 in the template 1 and the radius of curvature of the arc surface of the friction wheel consistent as R130mm-R190mm;

[0057] At the same time, make the roller device so that the processing gap between the roller and the roller arc groove 2 of the template 1 is 0.004-0.008mm, and the error of the radius of curvature is controlled within 0.004-0.008mm;

[0058] Then, start a lathe in an all-round way, take out the supporting plate s...

Embodiment 3

[0061] As shown in the figure, a method of using a profiling device for a friction wheel arc surface, the specific process steps are as follows:

[0062] First, according to the technical parameter requirements of the drawing, according to the radius of curvature of the friction wheel arc surface of the workpiece to be processed, a template 1 with the same curvature radius as the roller arc groove 2 is made; the curvature radius of the friction wheel arc surface is designed to be R130mm, Make the radius of curvature of the center line of the arc groove 2 of the roller in the template 1 and the arc surface of the friction wheel consistent as R130mm;

[0063] At the same time, make the roller device so that the processing gap between the roller and the roller arc groove 2 of the template 1 is 0.004mm, and the error of the radius of curvature is controlled within 0.004mm;

[0064] Then, start a lathe in an all-round way, take out the supporting plate screw mandrel in the large su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com