Workpiece improved structure used for assembling power transmission and distribution device

A technology for power transmission and distribution equipment and workpieces, which is applied in the field of improving the structure of workpieces for assembling power transmission and distribution equipment. It can solve problems such as the difficulty of moving toolboxes for assemblers, and achieve the effects of reducing the time to find workpieces, improving work efficiency, and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

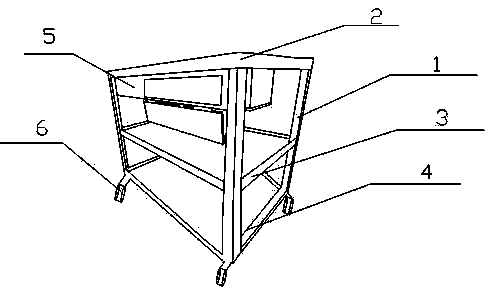

[0018] Such as figure 1 As shown, the present invention includes a cart body 1 , a tool box 5 and rollers 6 , and the cart body 1 is provided with a first placement layer 2 , a second placement layer 3 and a third placement layer 4 sequentially from top to bottom. Two of the first placement layer 2 , the second placement layer 3 and the third placement layer 4 are arranged parallel to each other and at equal intervals. The cart body 1 of this embodiment is a cuboid. The toolbox 5 of the present embodiment is welded on the top of the inside of the cart body 1, the length of the toolbox 5 is equal to the length of the cart body 1, and an opening and closing door panel is arranged on the front of the toolbox 5, and the opening and closing door panel has only one side for flexible connection On the edge of the bottom surface of the tool box 5, the opening and closing door panels can be opened and closed up and down. The tool box (5) is welded on the bottom of the first placement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com