Combined-type dredge ship

A combined, dredger technology, applied in special purpose ships, earth movers/shovels, mechanically driven excavators/dredgers, etc., can solve the problem of small excavation width, hydraulic oil leakage environment, shallow draft, etc. problem, to achieve the effect of increasing the excavation width and ensuring the total strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be explained in detail below in conjunction with the accompanying drawings.

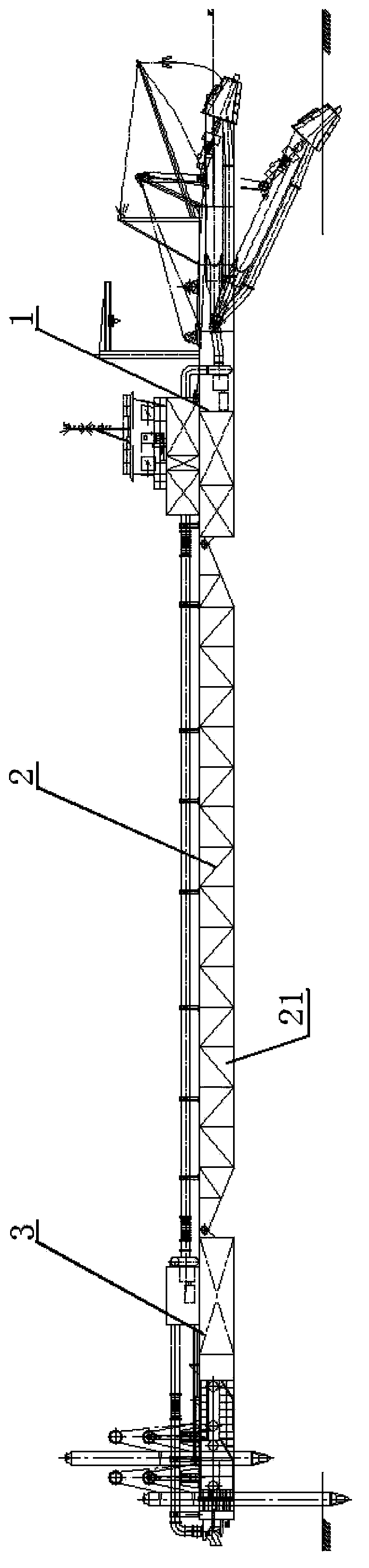

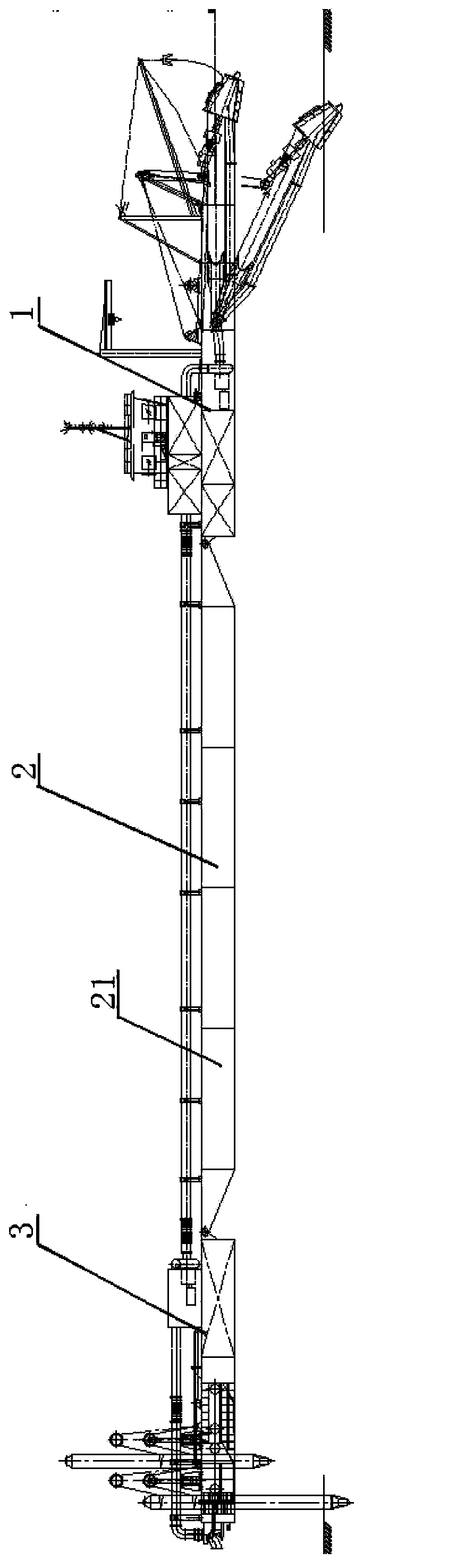

[0025] Such as figure 1 A combined dredger according to an embodiment of the present invention shown in , includes a bow 1 , a combined middle 2 and a stern 3 which are sequentially articulated. In the embodiment of the present invention, the detachable connection is preferably a hinge, and of course it may also be a detachable connection in other ways, which is not limited in this embodiment.

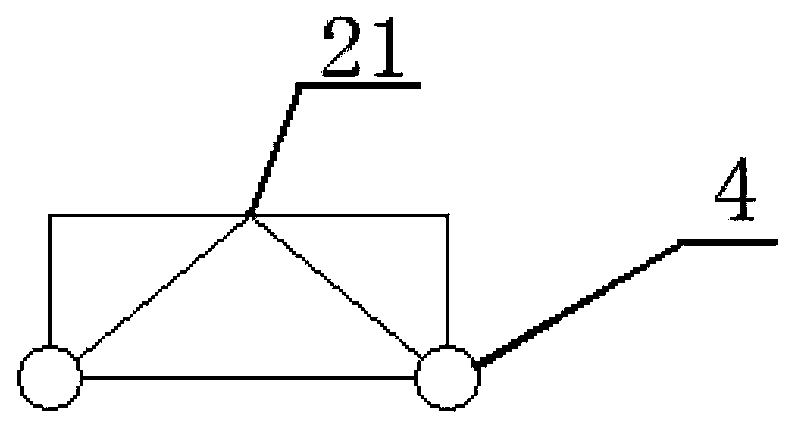

[0026] The combined middle part 2 includes several components 21, and the combined middle part 2 is hinged by several components 21 sequentially.

[0027] In the embodiment of the present invention, the bow and the stern of the hull are directly combined to form a complete dredger in engineering construction without a large dredging width.

[0028] The embodiment of the present invention adopts a detachably connected hull, which can not only ensure the shallow draft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com