Sliding wheel mechanism for lifting machine

A technology of hoisting machinery and pulleys, which is applied in the field of a device for changing the magnification of the pulley mechanism of large-scale hoisting machinery during work. The effect of convenient and fast operation, improved work efficiency, light and fast magnification conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

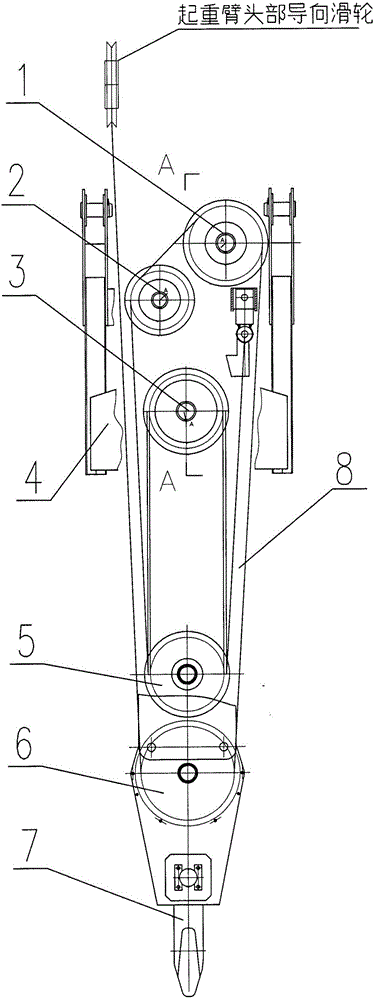

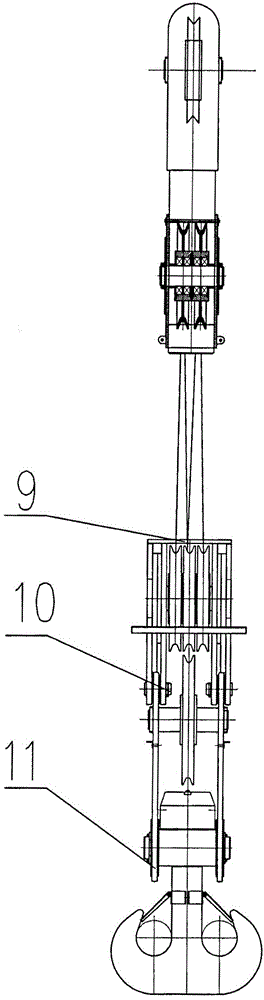

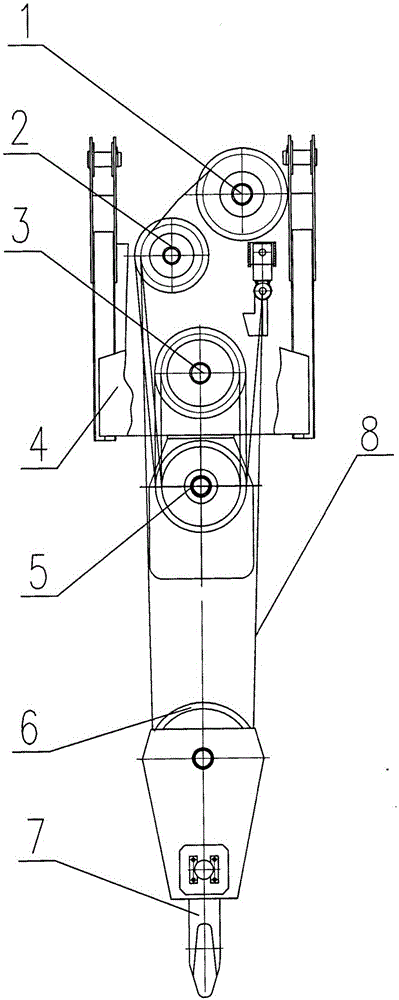

[0024] Such as figure 1 , 2 As shown, the pulley mechanism of the hoisting machine of the present invention includes and is installed on the fixed pulley block of the boom head, the first movable pulley block 5 installed on the first movable pulley bracket 9, the installation The second movable pulley block 6 and the suspension hook group 7 on the second movable pulley support 11; the described fixed pulley block is composed of two left and right fixed pulleys 1, 2 and a bottom fixed pulley block 3 arranged on the fixed pulley support top, and the first A movable pulley block is hoisted below the fixed pulley block by the traction wire rope 8, and the second movable pulley bracket 11 equipped with the second movable pulley block and the hook group 7 is combined with the lower end of the first movable pulley bracket through a detachable pin shaft 10; The axes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com