Method for continuously synthesizing tetradecyl acrylate through microwave-micro reactor catalysis

A technology of tetradecyl acrylate and micro-reactor, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve problems such as unsafe production process, sulfuric acid corrosion equipment, inaccurate temperature control, etc. Achieve the effect of reducing difficulty, improving purity and penetrating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

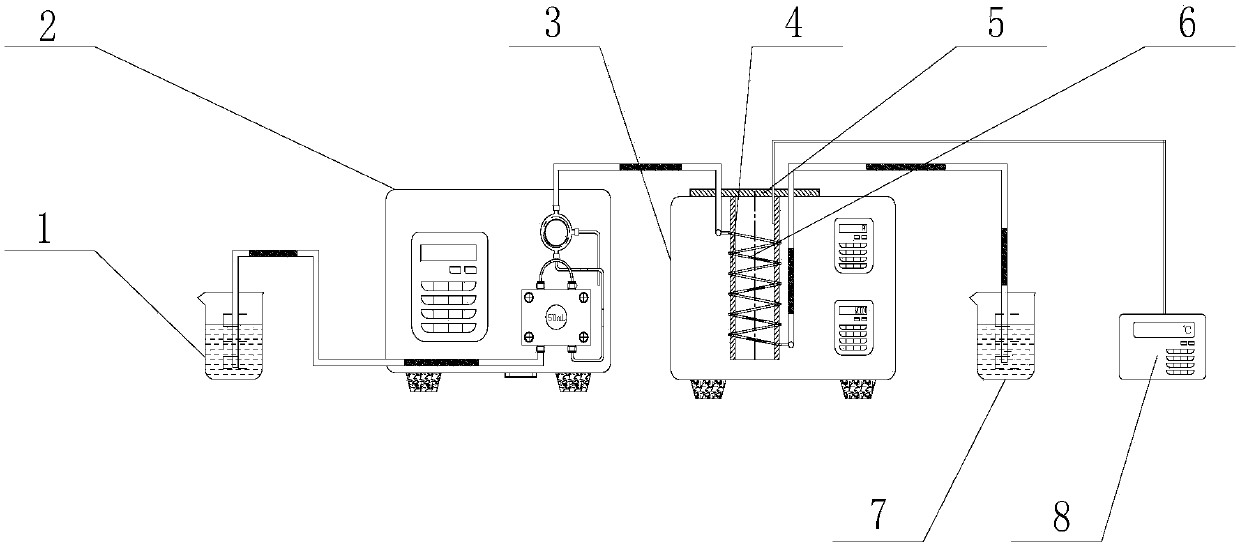

Method used

Image

Examples

Embodiment 1

[0038] The method of the present embodiment comprises the following steps:

[0039] Step 1. Put 50 g of tetradecyl alcohol in a water bath to heat and melt into a liquid, and then transfer it to the raw material mixed liquid beaker 1; the tetradecyl alcohol is a commercially available analytical reagent; the temperature of the water bath is 70° C.;

[0040] Step 2: Add 0.421g of hydroquinone and 0.561g of p-toluenesulfonic acid into the raw material mixed liquid beaker 1 filled with myristyl alcohol liquid in step 1, and then place the raw material mixed liquid beaker 1 in an ultrasonic oscillator for vibration and stirring , so that the solid particles are completely dissolved to obtain a mixed solution; the temperature of the shaking and stirring is 35° C., and the time is 4 minutes;

[0041] Step 3, adding 20.17g of acrylic acid and 45g of p-xylene to the mixed solution obtained in step 2, and then stirring evenly to obtain a raw material mixed solution; the stirring time i...

Embodiment 2

[0048] The method of the present embodiment comprises the following steps:

[0049] Step 1. Put 50 g of tetradecyl alcohol in a water bath to heat and melt into a liquid, and then transfer it to the raw material mixed liquid beaker 1; the tetradecyl alcohol is a commercially available analytical reagent; the temperature of the water bath is 70° C.;

[0050] Step 2: Add 0.431g of hydroquinone and 0.575g of p-toluenesulfonic acid into the raw material mixed liquid beaker 1 filled with myristyl alcohol liquid in step 1, and then place the raw material mixed liquid beaker 1 in an ultrasonic oscillator for vibration and stirring , so that the solid particles are completely dissolved to obtain a mixed solution; the temperature of the shaking and stirring is 35° C., and the time is 4 minutes;

[0051] Step 3, adding 21.85g of acrylic acid and 45g of p-xylene to the mixed solution obtained in step 2, and then stirring evenly to obtain a raw material mixed solution; the stirring time i...

Embodiment 3

[0056] The method of the present embodiment comprises the following steps:

[0057] Step 1. Put 50 g of tetradecyl alcohol in a water bath to heat and melt into a liquid, and then transfer it to the raw material mixed liquid beaker 1; the tetradecyl alcohol is a commercially available analytical reagent; the temperature of the water bath is 70° C.;

[0058] Step 2: Add 0.426g of hydroquinone and 0.568g of p-toluenesulfonic acid into the raw material mixed liquid beaker 1 filled with myristyl alcohol liquid in step 1, and then place the raw material mixed liquid beaker 1 in an ultrasonic oscillator for vibration and stirring , so that the solid particles are completely dissolved to obtain a mixed solution; the temperature of the shaking and stirring is 35° C., and the time is 4 minutes;

[0059] Step 3, adding 21.01g of acrylic acid and 45g of p-xylene to the mixed solution obtained in step 2, and then stirring evenly to obtain a raw material mixed solution; the stirring time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com