Method for eliminating clamp effect on seepage-proofing film anchoring part of high film faced rockfill dam by compensating displacement

A technology of anti-seepage membrane and high-membrane film, which is applied in the direction of dams, barrages, and water conservancy projects. It can solve problems such as abandonment by builders, difficulty in implementation, and complicated technological processes, and achieve the effect of reducing displacement and speeding up construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

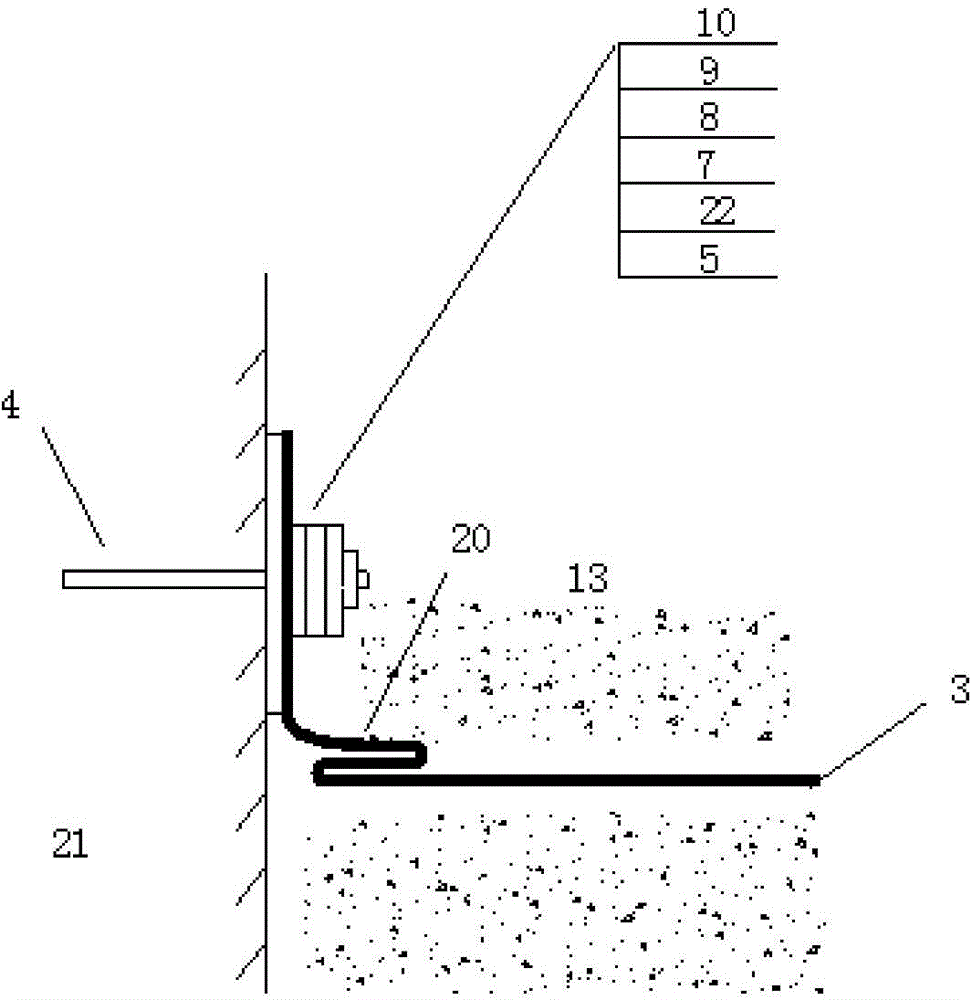

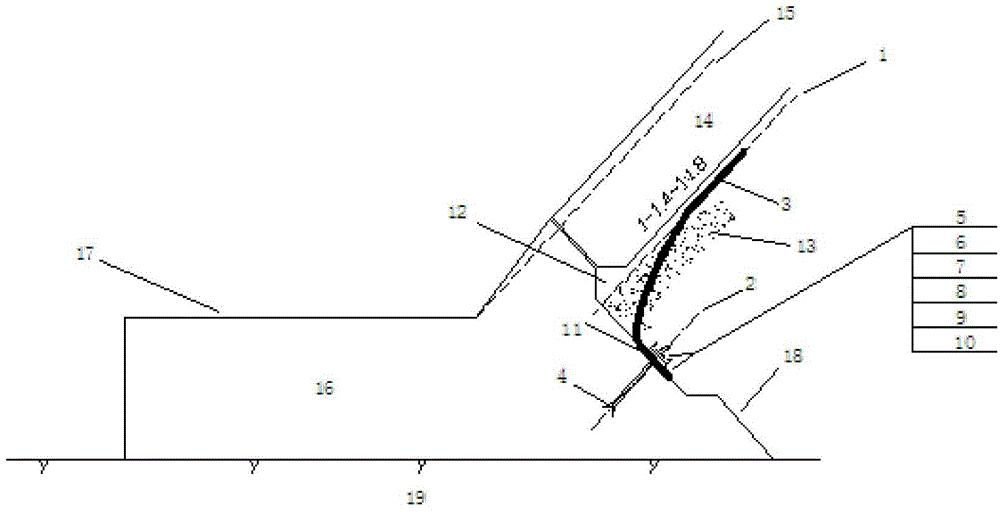

[0029] figure 2 Pour the plinth on the bedrock 19 around the upstream surface of the middle dam, and embed the stainless screw 4 along the membrane anchor line 2. The cross-sectional shape of the plinth is shown in 16, wherein the bevel 18 of the plinth is provided with a ground anchor base 10;

[0030] After the dam filling is completed, leave an underfilled area near the downstream side of the toe plate anti-seepage, and place a film roll to be anchored on the straight section 17 of the toe plate;

[0031] Lay the anchoring edge of the anti-seepage membrane 3 from the top of the toe plate to the slope of the anti-seepage downstream side of the toe plate, and cover the screw 4 with the round hole on the membrane designed in advance. At this time, the concave concrete surface has been coated with a sealant layer 11, The lower rubber belt 9 has been put on the screw and laid on the sealant layer, and the film is on the lower rubber belt 9;

[0032] Put the screw rod on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com