Automobile air conditioner air outlet assembly assembly testing device

A detection device and assembly assembly technology, which is applied to measuring devices, assembling machines, instruments, etc., can solve the problems of low installation accuracy, weak connection, missing and wrong installation, etc., to achieve stable and accurate measurement results and improve equipment integration. to eliminate the effect of improper installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

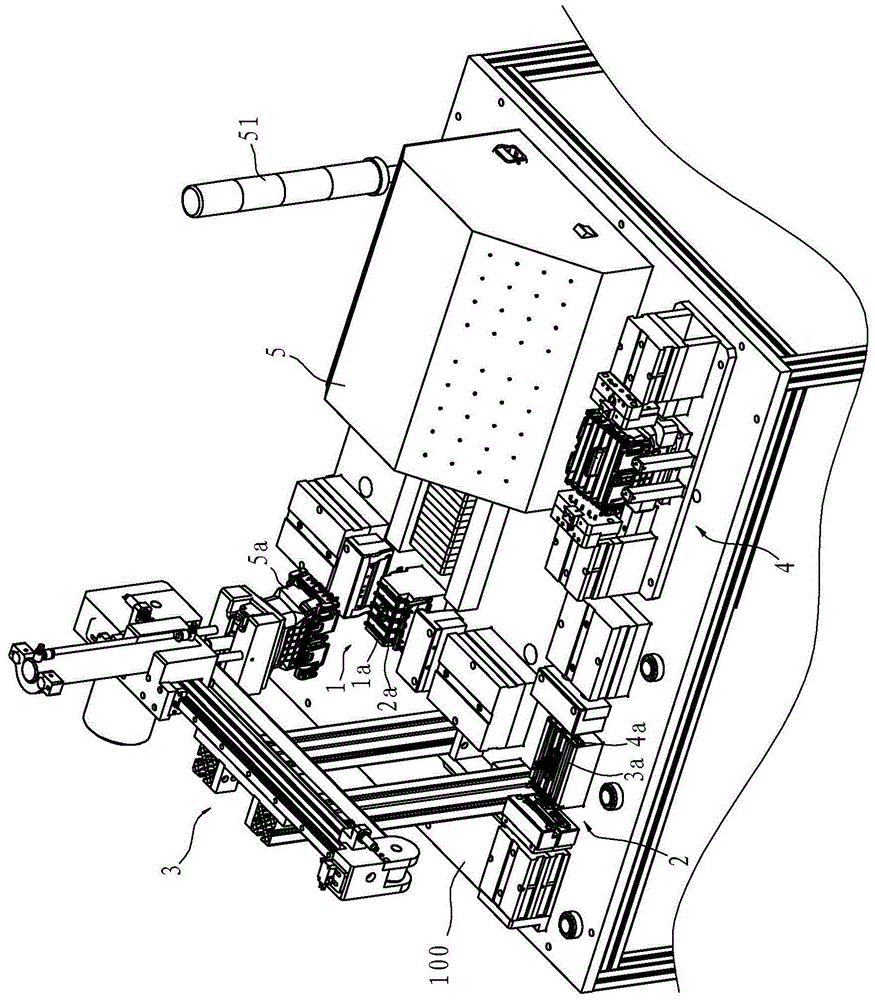

[0052] Example 1, such as figure 1 As shown, the automobile air conditioner air outlet assembly assembly detection device in this embodiment includes a worktable 100, a vertical blade connecting rod assembly mechanism 1, a horizontal blade connecting rod assembly mechanism 2, a shell transplanting assembly mechanism 3, and an air outlet assembly mechanism. Into a detection mechanism 4, a control cabinet 5 and an audible and visual alarm device 51.

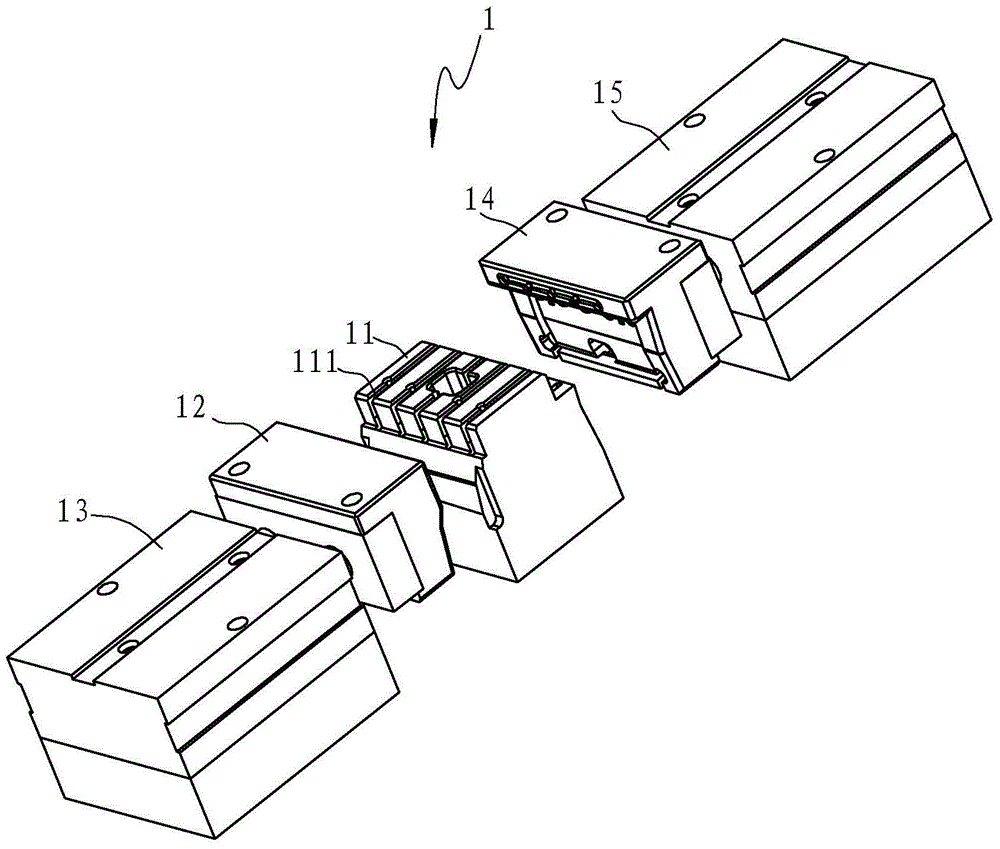

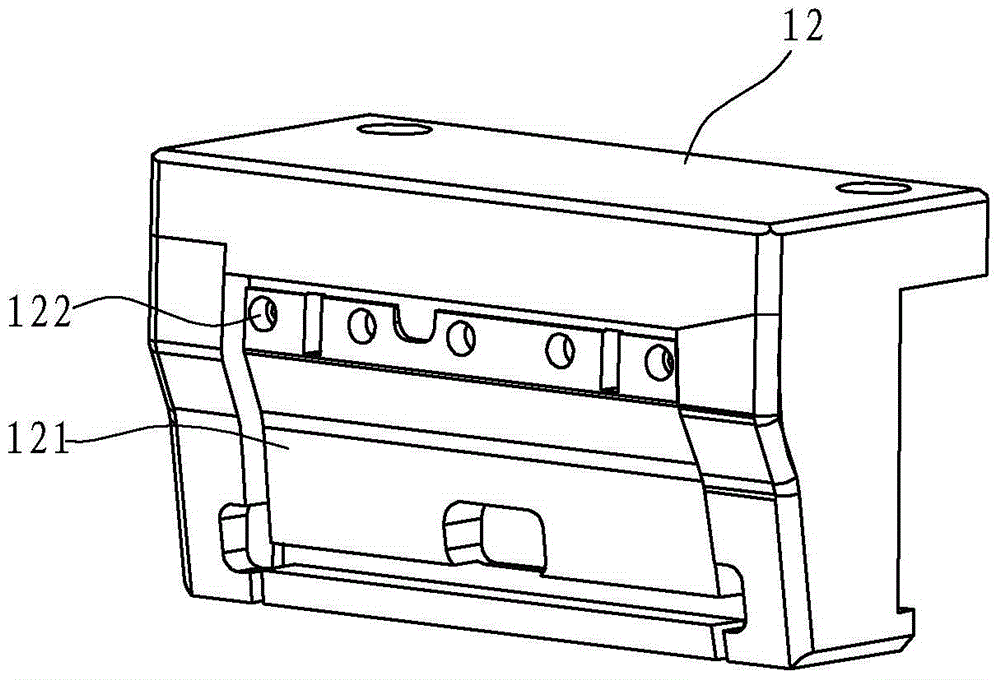

[0053] combine figure 2 and image 3 As shown, the vertical blade connecting rod assembly mechanism 1 is arranged on the worktable 100 and can assemble a plurality of vertical blades 1a and vertical connecting rods 2a into one body, specifically including the vertical blade fixing seat 11, the first connecting rod cylinder and In the second connecting rod cylinder, the upper end surface of the vertical blade fixing seat 11 has a plurality of slots 111 for the vertical blade 1a.

[0054]The first connecting rod cylinder 13 is ar...

Embodiment 2

[0066] Embodiment 2. After the air outlet assembly 6a is assembled in this embodiment, it can be moved from the horizontal blade mounting seat to the air outlet assembly detection mechanism through the moving mechanism without manual operation. Refer to Embodiment 1 for other structures.

[0067] to combine Figure 8 As shown, wherein, the moving mechanism includes a support 51 , a first translation cylinder 52 , a first vertical cylinder 53 and a first clamping cylinder 55 . The support 51 is located on the worktable 100; the first translation cylinder 52 is located on the support 51 and has a horizontal power output end, the first vertical cylinder 53 is located on the power output end of the first translation cylinder 52, and There is a vertically downward power output end, the first clamping cylinder 55 is arranged on the power output end of the first vertical cylinder 53 and can clamp the air outlet housing assembly 6a, the first clamping cylinder 55 has a chuck 551 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com