Single shaft framework angle adjustment system

A technology of angle adjustment and frame, applied in the direction of control using feedback, etc., to achieve the effect of improving output accuracy, facilitating sinusoidal distribution, and real-time angle tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

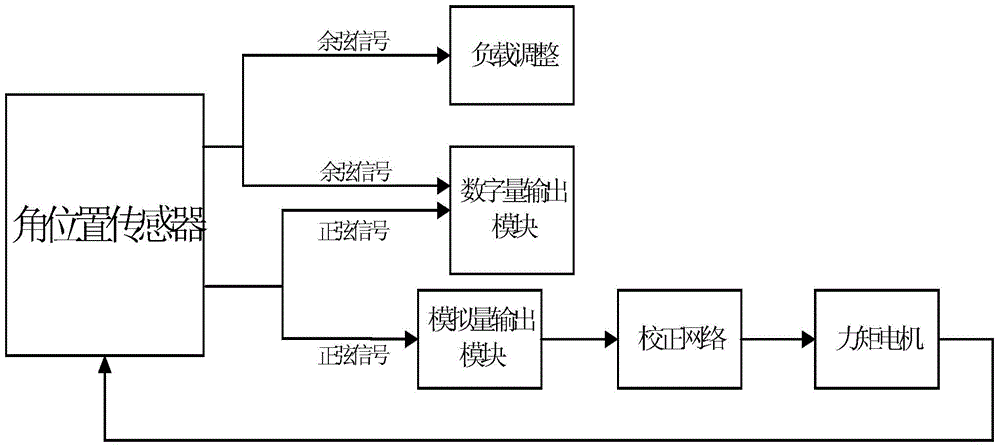

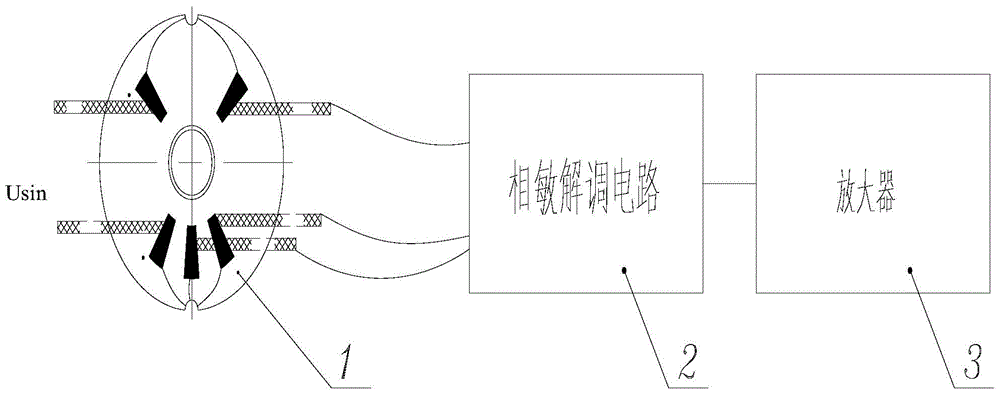

[0057] (1) Install the angle sensor stator (1) with an outer diameter of Φ90mm, an inner diameter of Φ70mm, and a thickness of 22m; a rotor (2) with an outer diameter of Φ69.4mm, an inner diameter of Φ51mm, and a thickness of 22mm on the shaft end of the single-axis frame, and adjust the coaxiality of the stator and rotor Degree ≤ 0.01mm, excited by the rotor, the stator completes the signal output.

[0058] (2) The two output voltage signals of the stator sine and cosine of the angle sensor are transmitted to the digital output module by the signal connection cable, and the angle digital output of the angular position sensor is completed, which is provided to the subsequent sampling system.

[0059] (3) Adjust the load resistance in the digital output module until the load resistance of the digital output module is consistent with the load resistance of the analog output module, so that the digital output accuracy of the angular position sensor meets the system requirements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com