Vertical rotary high-voltage metal-enclosed switchgear valve mechanism

A metal-enclosed and switchgear technology, applied in the direction of pull-out switchgear, switchgear, electrical components, etc., can solve the problems of safety, reliability and convenience of unfavorable equipment, occupying limited space of the switchgear, and many transmission links, etc., to achieve the design principle Unique and novel, reasonable and compact structure, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be further described below in conjunction with the drawings, but the actual manufacturing structure of the present invention is not limited to the embodiments shown in the drawings.

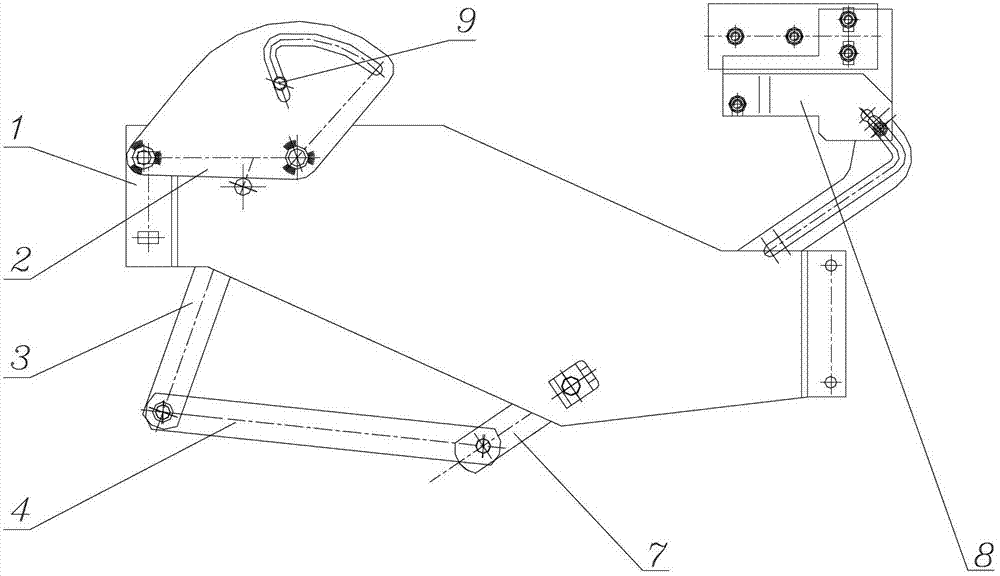

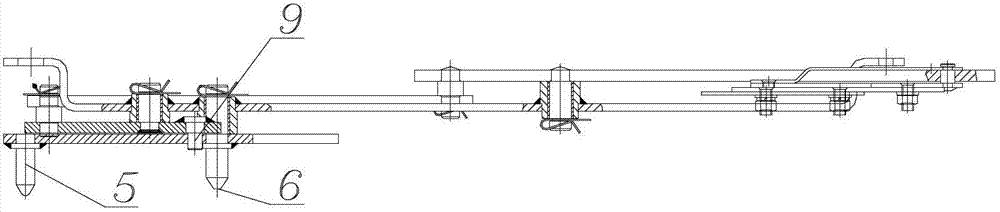

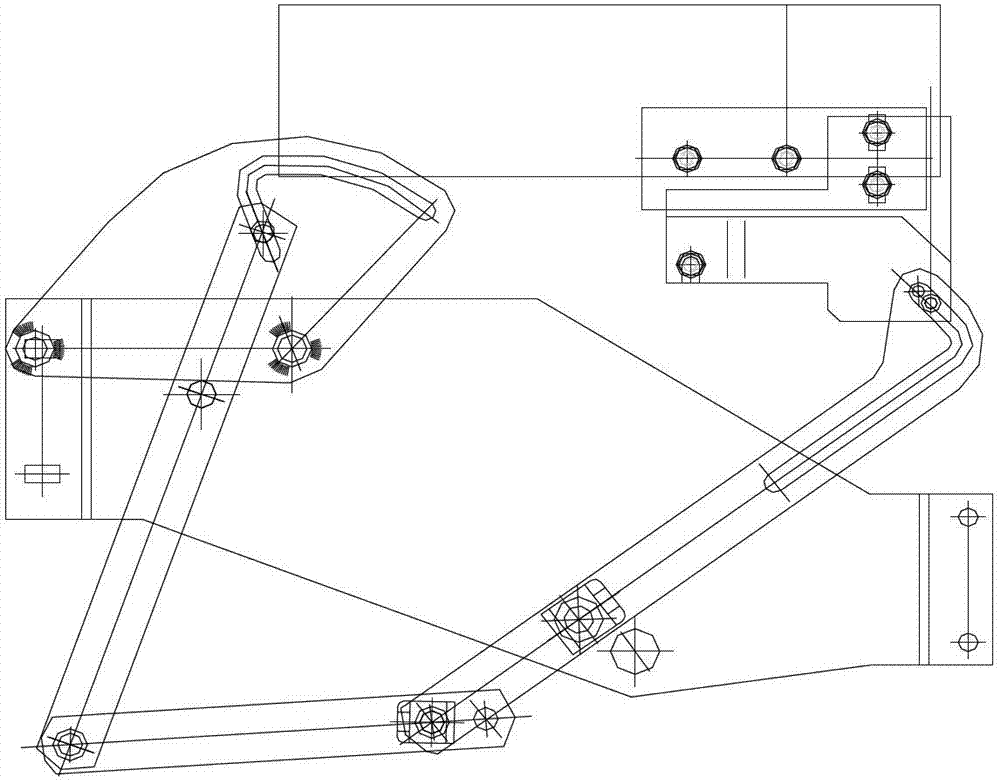

[0016] Referring to the accompanying drawings, the valve mechanism of the vertical-rotation high-voltage metal-enclosed switchgear of the present invention includes a mounting base plate 1, a linkage mechanism composed of rear, middle, and front three swing rods 3, 4, and 7, and a fan-shaped drive plate 2. And components such as the three-plate device 8 that connects valve. There are three rotation fulcrums distributed on the installation substrate 1, one of which is used to install the fan-shaped drive plate 2, and the other two rotation fulcrums are respectively used to connect the rear swing link 3 and the front swing link 7 of the linkage mechanism. The front swing link 7 in the link mechanism bar is connected with a three-plate device 8 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com