a line device

A pay-off device and state-of-the-art technology, used in transportation and packaging, conveying filamentous materials, thin material handling, etc., can solve problems such as inadequate management, loud startup noise, mechanical vibration, etc., achieve a simple and practical structure, and improve production. Efficiency, the effect of faster loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention discloses a wire pay-off device, which solves the phenomenon that the existing equipment damages the work plate inadvertently, improves the guarantee for safe production, and reduces unnecessary losses.

[0023] The technical solutions in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention.

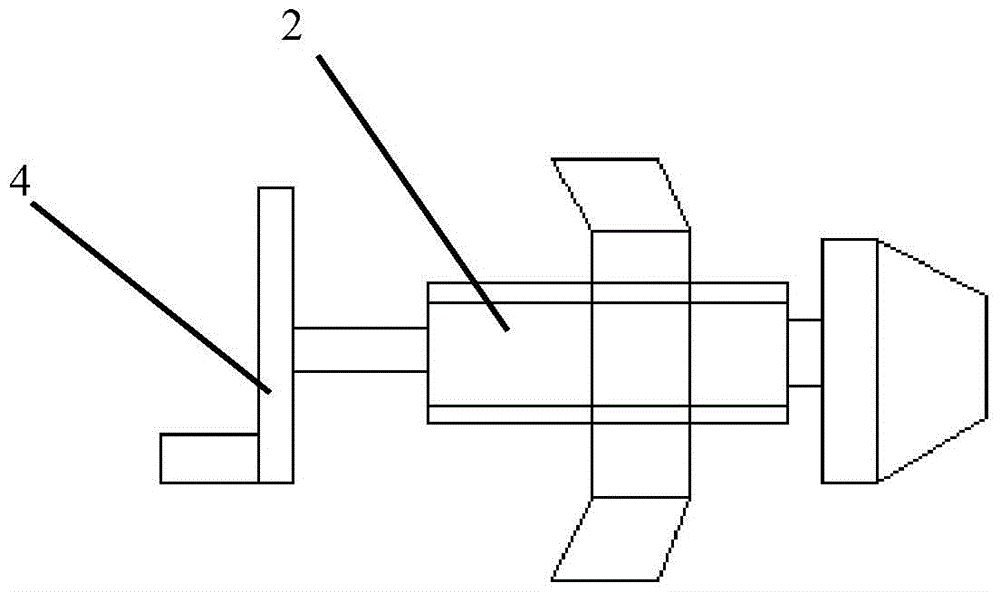

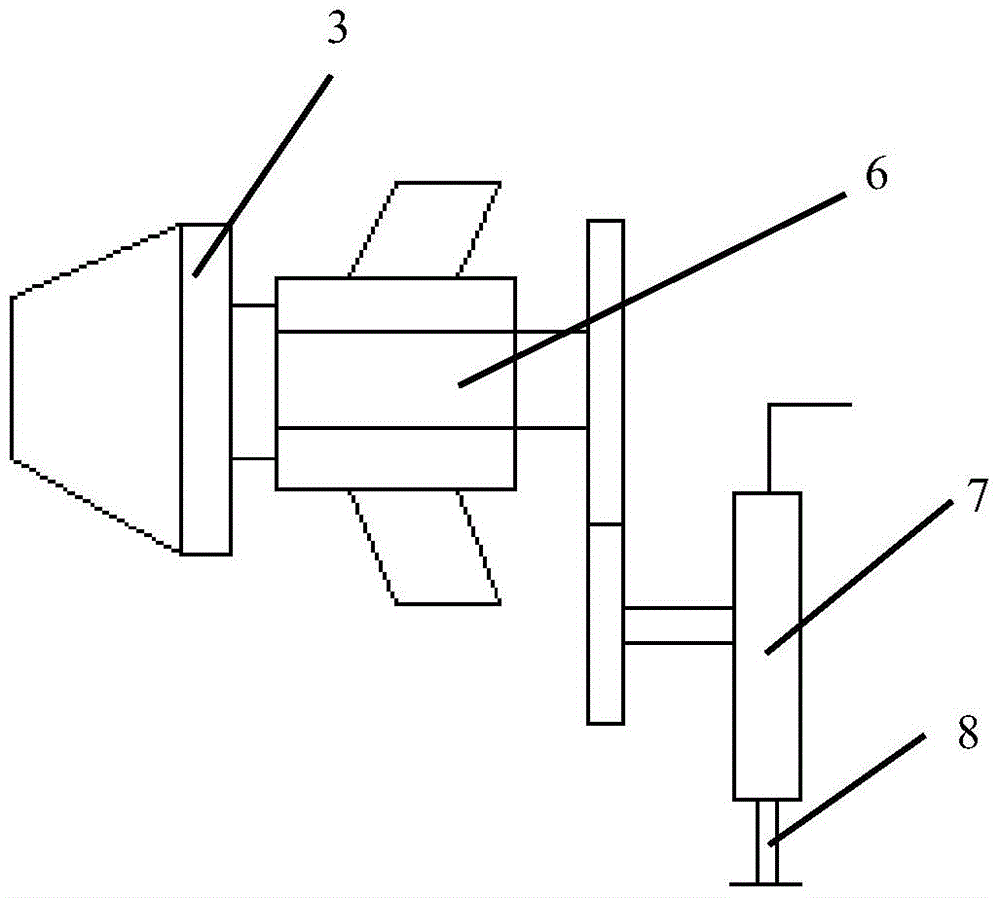

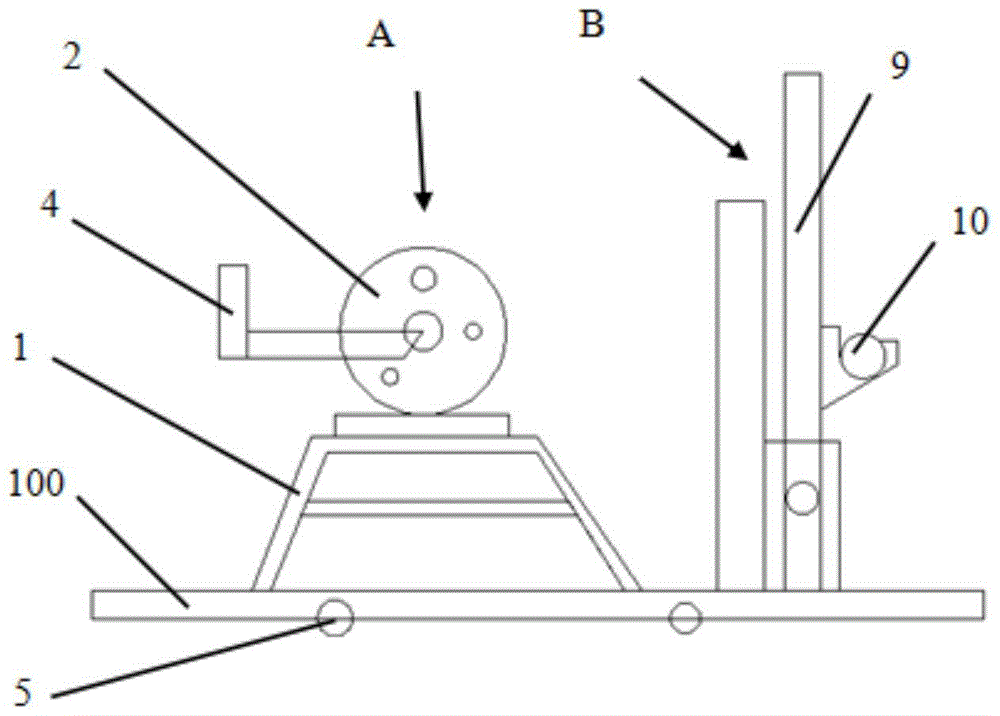

[0024] like figure 1 and figure 2 As shown, the pay-off device disclosed in the present invention includes an iron plate 100 , a pay-off frame 1 disposed on the iron plate 100 , and a pay-off tip 2 and a push rod 3 disposed on the pay-off frame 1 . The pay-off top 2 is a trapezoidal anti-thread propelling rod. The head of the pay-off top 2 is designed in a conical shape, and the taper is used to lift the tray so that it can run 1-1.5 cm above the ground, and there is no need to reconnect with the original The device is lifted, and the screw rod can be avoided from shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com