Water-soluble fabric assembly line

An assembly line, water-soluble cloth technology, applied in the field of embroidery, can solve problems such as poor extension strength and pressure strength, and achieve the effect of reducing costs, reducing mesh stitching time and the use of stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention discloses a water-soluble cloth assembly line capable of reducing the sewing time of mesh cloth and the use of suture threads. The present invention is mainly applied in the field of embroidery industry.

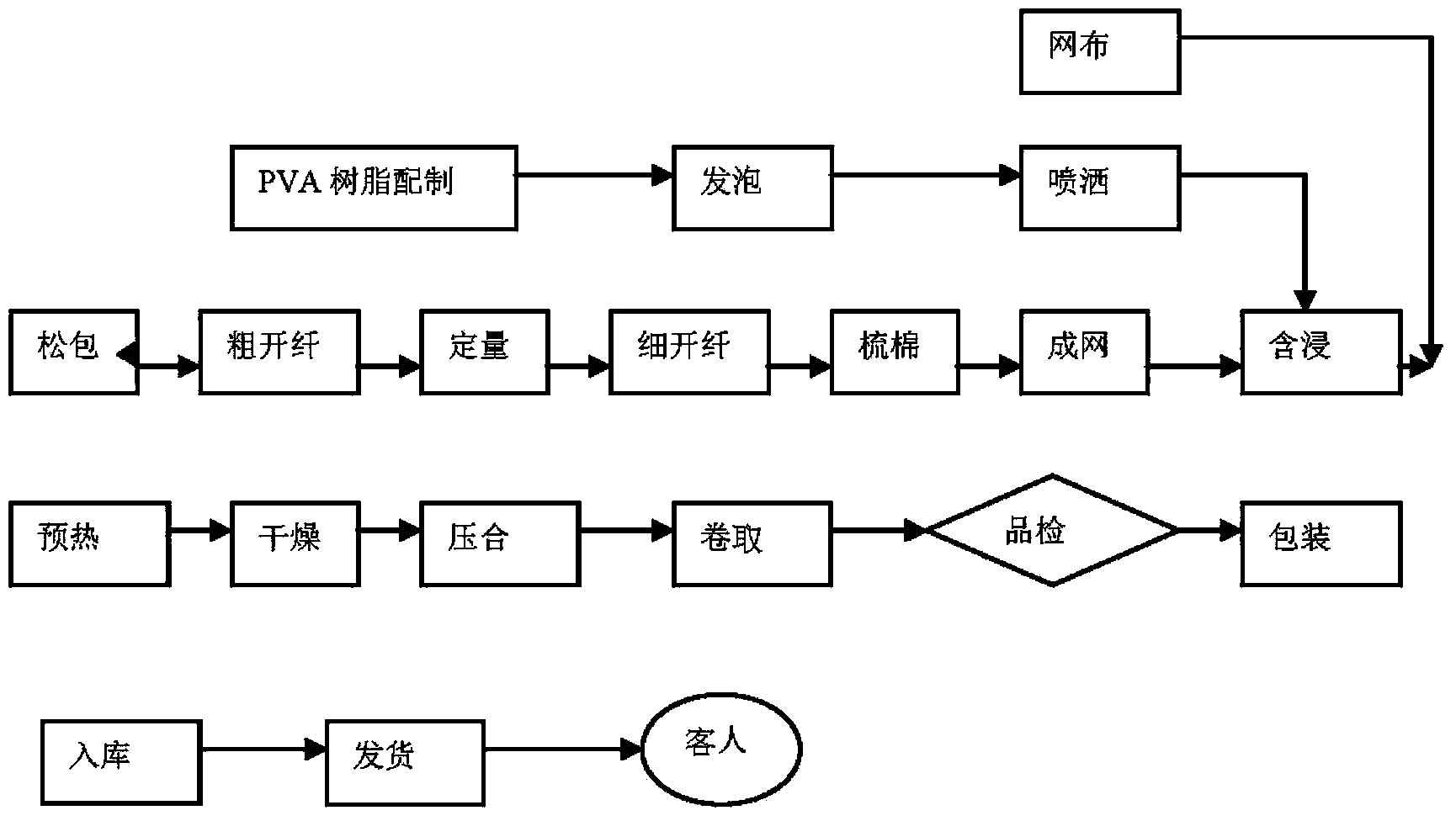

[0014] like figure 1 As shown, the water-soluble cloth assembly line disclosed in the present invention handles water-soluble fibers, which includes the processes of loosening, coarse opening, quantification, fine opening, carding, web forming, containing invasion, preheating, drying, and pressing and coiling. The water-soluble cloth production line also uses mesh cloth, and before the preheating process, an adhesive PVA resin is added to make the water-soluble fiber and mesh cloth composite together. This kind of composite method has not been adopted in the production process of other products. Therefore, this production method is a unique process. After coiling, the product will be inspected for quality. After passing the inspection, it will be pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com