Cloth discharge frame structure of sanding machine

A technology of sanding machine and cloth rack, which is applied in the direction of textile and paper making, roughening, fabric surface trimming, etc. It can solve the problems of processing hidden dangers and other problems, and achieve the effect of avoiding hidden dangers and eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

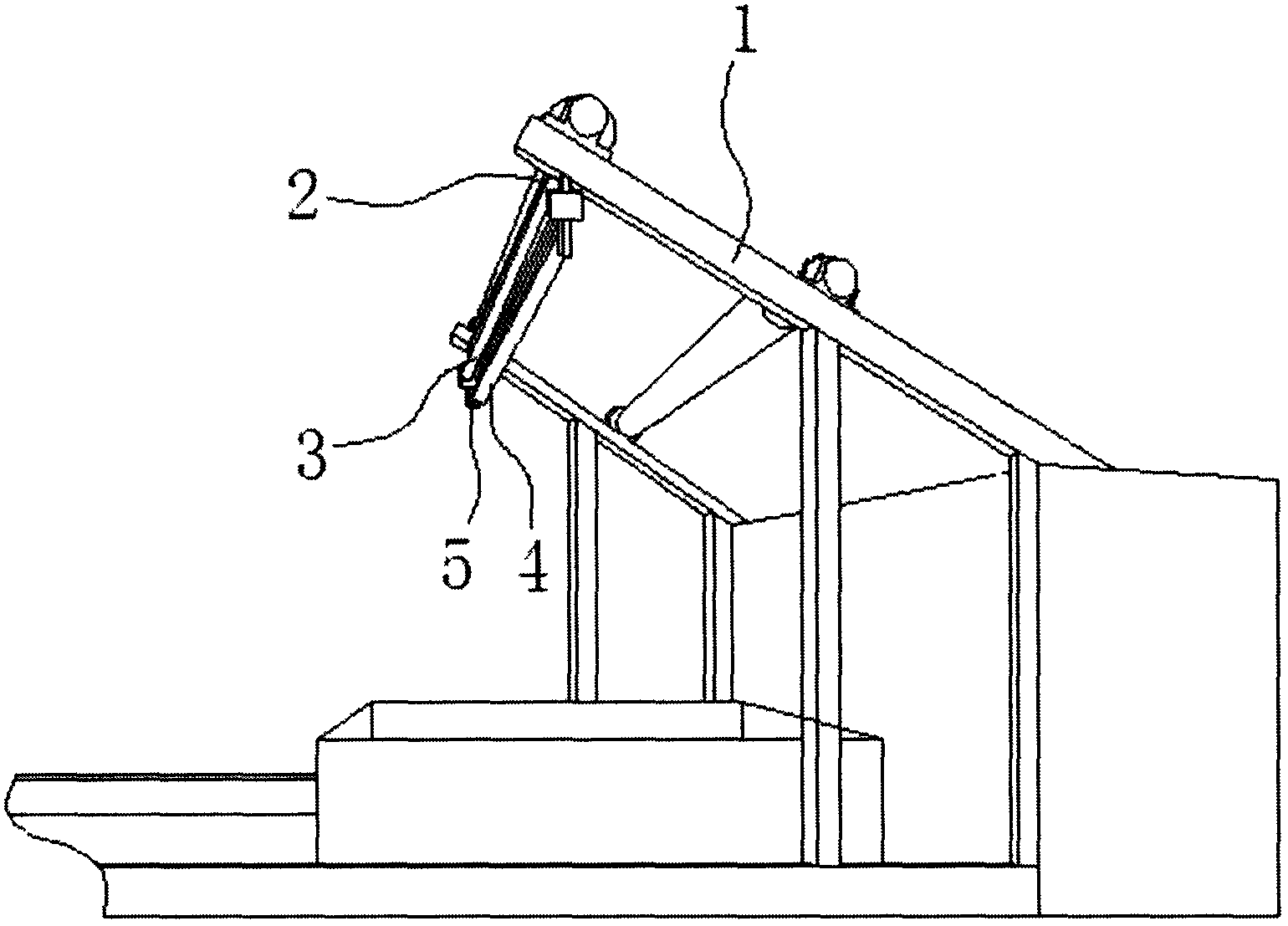

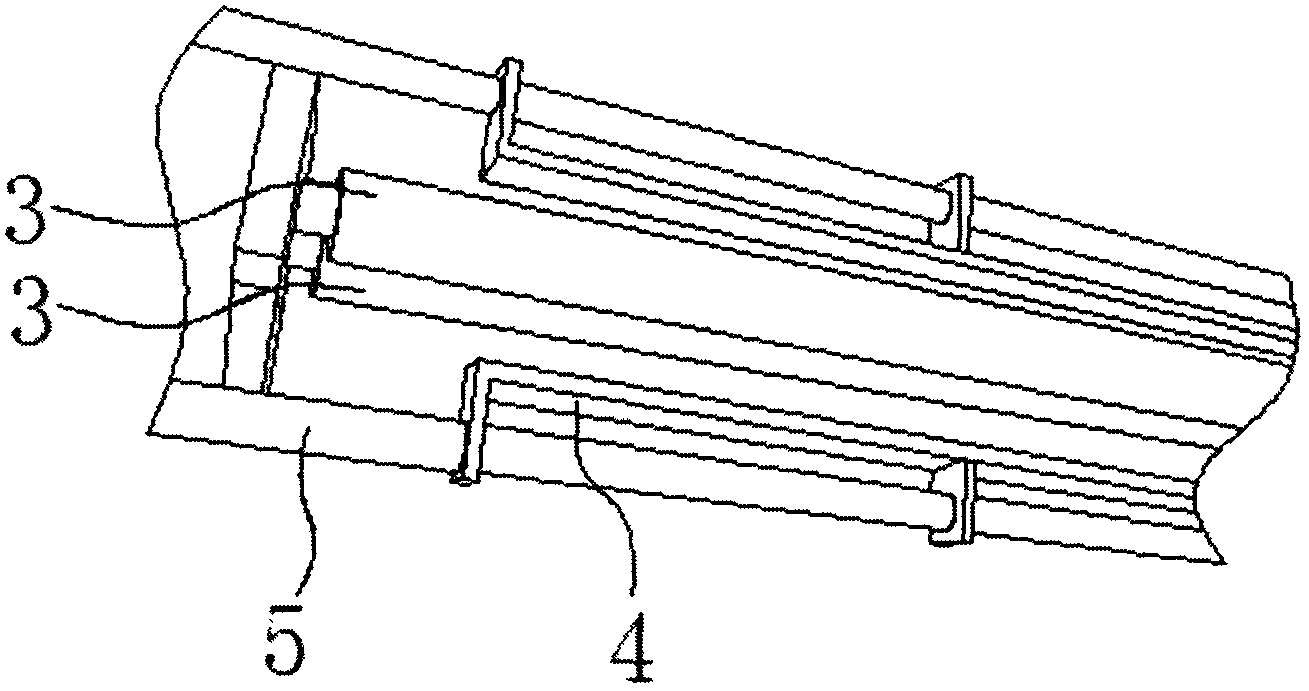

[0019] Such as figure 1 , 2 As shown, a cloth outlet frame structure of a sanding machine includes a cloth outlet frame body 1, a cloth guide roller 2 and a swing roller 3; the cloth guide roller 2 is rotatably supported on the front end of the cloth outlet frame body 1; The swing frame 3 is arranged below the cloth guide roller 2; the swing roller 3 is arranged below the cloth guide roller 2; there are two swing rollers 3, and the two swing rollers 3 are arranged side by side at intervals A cloth outlet is formed; a static eliminator 4 is also included; the static eliminator 4 is a group of two, and the two static eliminators 4 are symmetrically arranged on the outer sides of the two swing rollers 3 .

[0020] It also includes a support rod 5, two of which are fixedly supported on the front end of the cloth outlet frame body 1, and the static eliminator 4 is fixed on the support rod 5.

[0021] The static eliminator 4 is rod-shaped.

[0022] Since the present invention add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com