Steel-concrete combined beam plate structure for small bridge culvert

A steel-concrete composite beam and plate structure technology, applied in bridges, buildings, etc., can solve the problems of reduced strength and weak connection, and achieve the effects of light weight, good mechanical properties and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

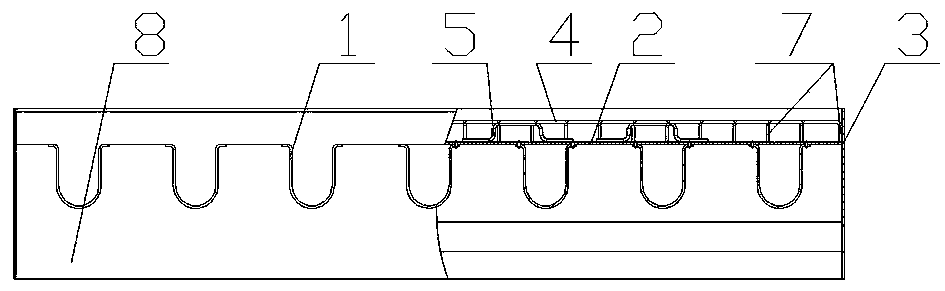

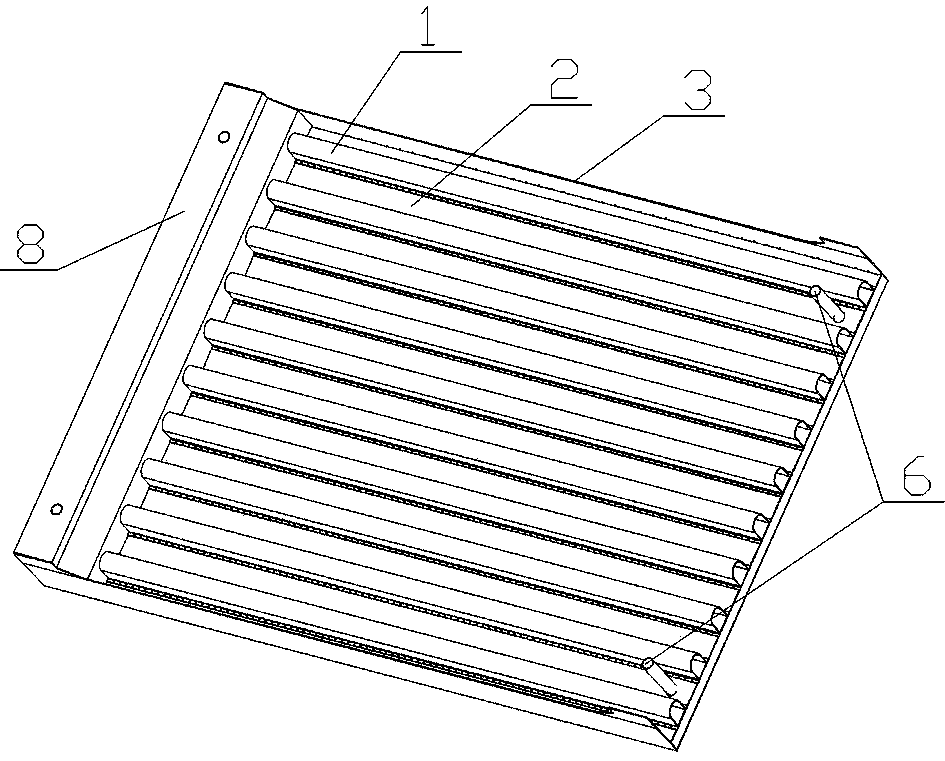

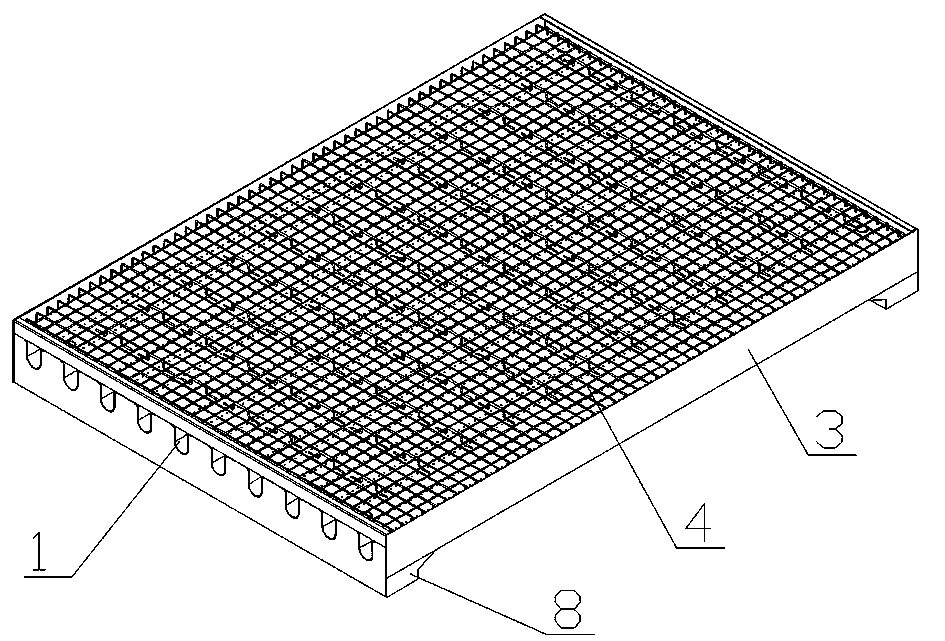

[0021] See attached figure 1 , a steel-concrete composite beam-slab structure of a small bridge and culvert, the structure includes a connecting seat 8 and a steel-concrete composite bridge culvert panel arranged above the connecting seat 8 at both ends, the key is that the structure of the steel-concrete composite bridge culvert panel includes a steel The bridge deck 2, two or more sets of U-shaped ribs 1 arranged parallel to the axial direction below the steel bridge deck 2, and the connecting seat 8 is provided with a groove 8-1 matching the U-shaped ribs 1. The U-shaped rib 1 cooperates with the groove 8-1, first, it can increase the contact area, prevent stress concentration, and second, it can facilitate the positioning of the steel-concrete composite bridge and culvert panels.

[0022] A steel mesh 4 is fixed above the steel bridge deck 2, and the steel mesh 4 is connected with the steel bridge deck 2 by means of supporting connectors 5 to form a grid structure, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com