Direct-current fan structure

A technology of electric fans and DC motors, which is applied in the field of structural innovation of DC electric fans, can solve problems such as energy consumption, consumption, and energy loss, and achieve the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this way, in order to enable the public to fully understand the structure of the DC fan described in the present invention, the illustrations are attached as follows:

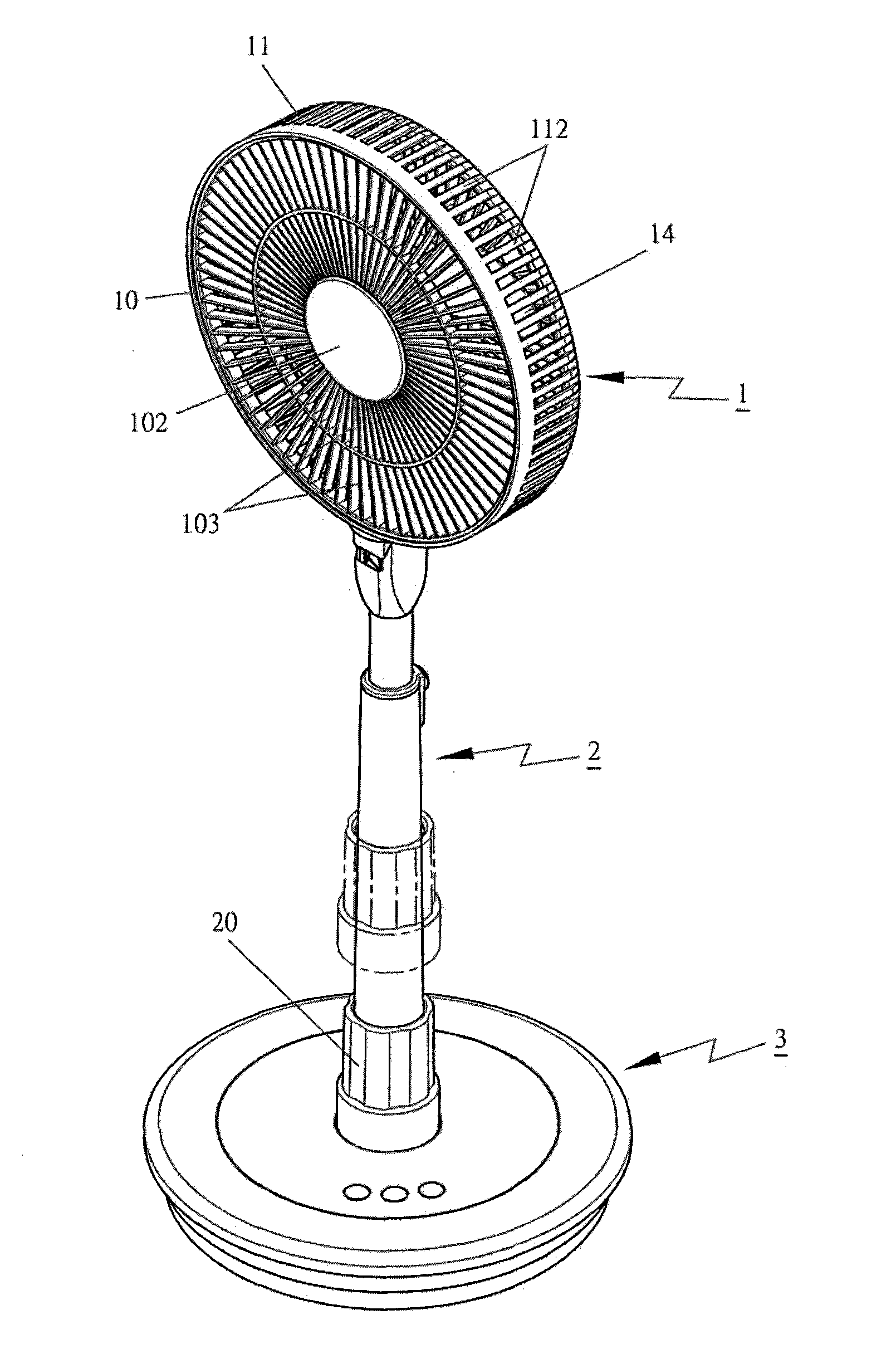

[0034] Such as figure 1 As shown, the DC electric fan structure of the present invention at least includes three main components: fan body 1 , connecting rod 2 and base 3 . The rear side of the sector 1 is connected with the connecting rod 2 so that the weight of the sector 1 can be supported by the connecting rod 2 . The above-mentioned base 3 has to be set on the ground or on a desktop or above various planes, so that the electric fan can be used more conveniently.

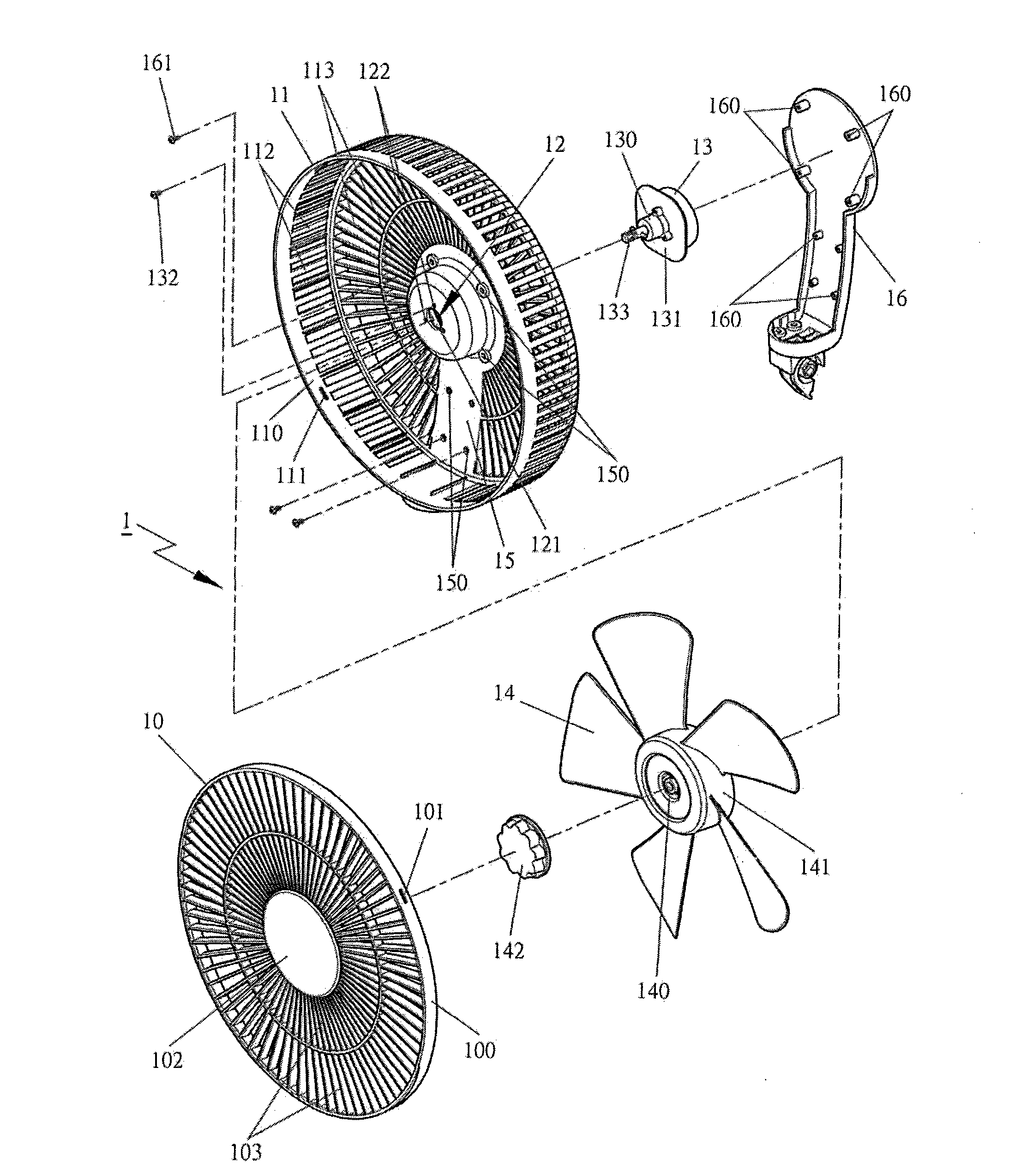

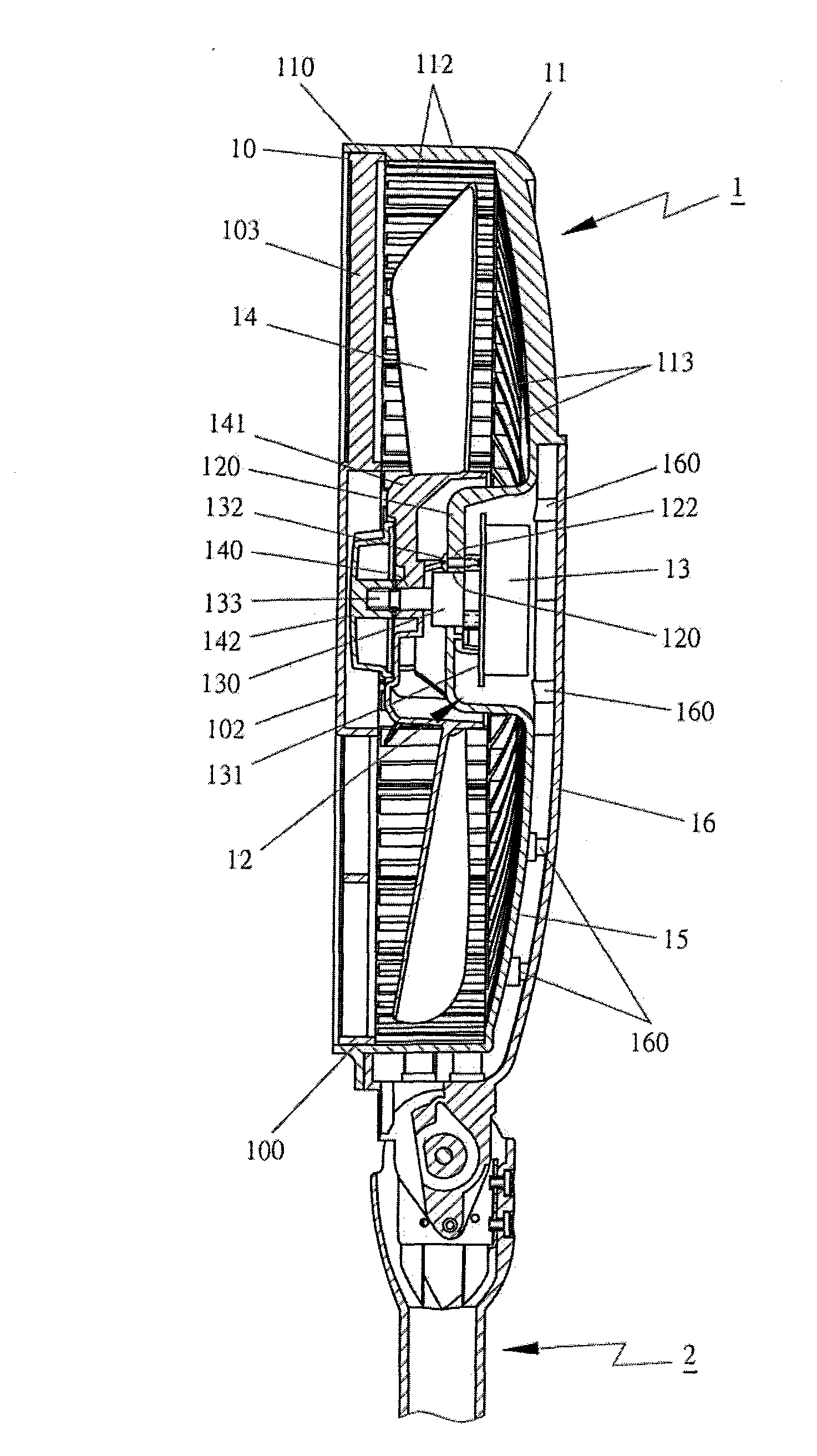

[0035] Such as figure 2 and 3 As shown, the aforementioned fan body 1 is provided with front and rear guard nets 10, 11, the aforementioned front guard net 10 is provided with a surrounding edge 100, and a plurality of engaging holes 101 or engaging grooves are arranged on the aforementioned surrounding edge 100 to match the rear gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com