Flow guide disk of multistage impeller centrifugal pump

A technology of centrifugal pumps and deflectors, which is applied to components, pumps, and pump components of elastic fluid pumping devices, and can solve problems such as increased volume loss, increased water retention time, and hydraulic loss, and achieve lifting work Efficiency and the effect of shortening the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

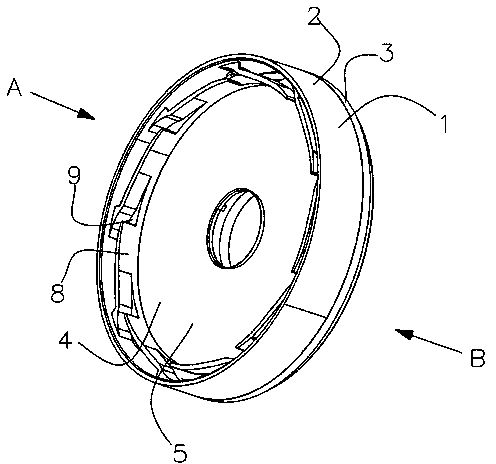

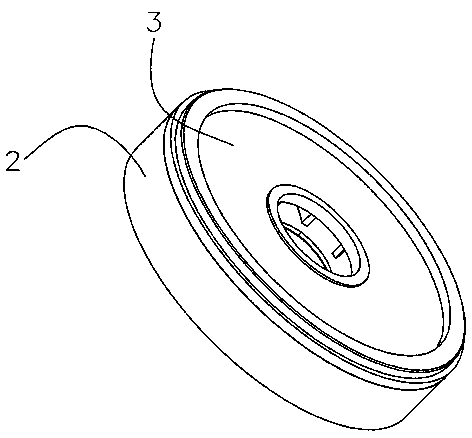

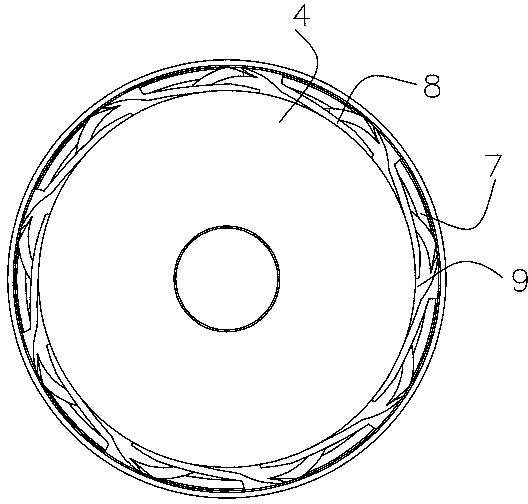

[0018] Such as Figure 1-4 As shown, the guide plate of a multi-stage impeller centrifugal pump provided in this embodiment includes a disc body 1, and the disc body 1 in the above is mainly composed of a disc seat 2 and a disc cover 3, wherein the disc seat 2 is divided into an upper chamber 6 and a lower chamber 5 by a middle partition 4, and a water passage hole 7 passing through the upper chamber 6 and the lower chamber 5 is evenly distributed on the periphery of the middle partition 4, and each Each water passing hole 7 corresponds to a baffle plate 8, the bottom surface of the above-mentioned baffle plate 8 is fixed with the bottom surface of the lower chamber 5 by ultrasonic welding technology, and one end thereof is ultrasonically welded on the inner side wall of the above-mentioned lower chamber 5 and the tangent line at the intersection of the two forms an included angle of 20°, and a water inlet opening 9 is formed between the other end and the adjacent baffle 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com