Hydraulic pressurizing energy recovery system and control device

A technology for boosting energy and recovering system, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, fluid pressure converter, etc. The effect of large inertia and hydraulic shock, volume reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

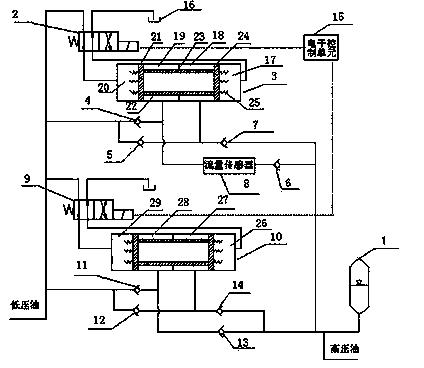

[0024]In the figure, 1. accumulator, 2. first solenoid valve, 3. first hydraulic booster, 4. first check valve, 5. second check valve, 6. third check valve, 7 , the fourth one-way valve, 8, the flow sensor, 9, the second solenoid valve, 10, the second hydraulic booster, 11, the fifth solenoid valve, 12, the sixth solenoid valve, 13, the seventh solenoid valve, 14 , the eighth solenoid valve, 15, the electronic control unit, 16, the oil tank, 17, the low-pressure chamber on the right side of the first hydraulic booster, 18, the high-pressure chamber on the right side of the first hydraulic booster, 19, the first hydraulic booster Left high pressure chamber, 20, left low pressure chamber of the first hydraulic booster, 21, left piston head, 22, piston rod, 23, sub-cavity layer, 24, right piston head, 25, spring, 26, the first Second hydraulic booster right side low-pressure chamber, 27, the second hydraulic booster right side high-pressure chamber, 28, the second hydraulic boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com