Remote finite element analysis method serving for industry alliance

A finite element and alliance technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that remote finite element analysis methods cannot serve industry alliances, improve the level of product performance analysis, overcome finite element effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

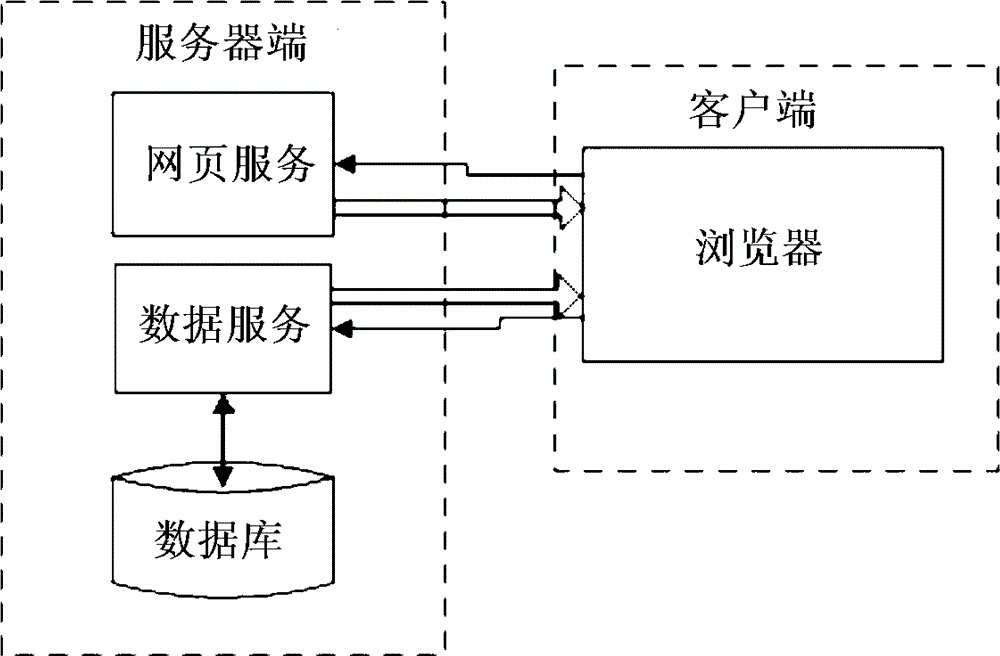

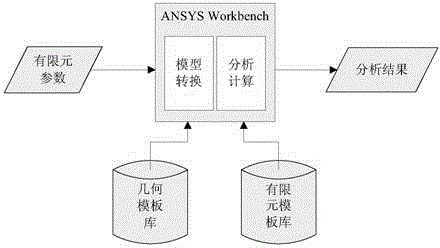

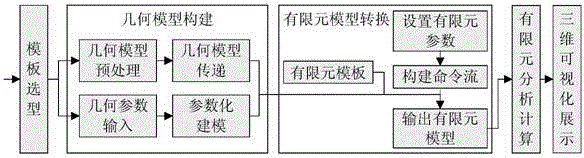

[0051] Refer to attached figure 1 ~ attached Figure 7 :

[0052] A remote finite element analysis method for a service industry alliance, comprising the following steps:

[0053] 1) Finite element template extraction of similar products; according to the structural characteristics and bearing characteristics of the product, analyze the mechanical model, material properties, mesh division method and boundary conditions of the characteristic structure, program these processes, and perform finite element template extraction , the boundary condition type is fixed, and the analysis process is parameterized;

[0054] 1.1) The type of boundary conditions is fixed; the finite element analysis uses the method of mathematical approximation to Department of Physics The simulation can be simplified as solving differential equations, and the variable values that need to be limited to obtain differential equations are called boundary conditions; in finite element analysis...

Embodiment 2

[0094] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , take the connecting rod as an example to further illustrate the present invention. The connecting rod is an important part connecting the engine piston and the crankshaft, and is mainly divided into a flat notch connecting rod and an oblique notch connecting rod. The function of the connecting rod in the engine industry is similar to the mechanical model. This paper takes the flat cut connecting rod as an example.

[0095] A remote finite element analysis method for the service industry alliance, the steps of using this invention are as follows:

[0096] 1) Finite element template extraction of similar products. According to the structural features and load-bearing characteristics of the product, analyze the mechanical model, material properties, meshing method and boundary conditions of the characteristic structure, program these processes, extract the finite element tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com