A low-cost and continuously adjustable DC ice melting and svg device

A low-cost DC ice-melting technology, used in cable installation, overhead installation, flexible AC transmission systems, etc., can solve the problems of cumbersome operation, inconvenient transportation, low device utilization, etc. The ice workload is small and the effect of increasing the configuration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

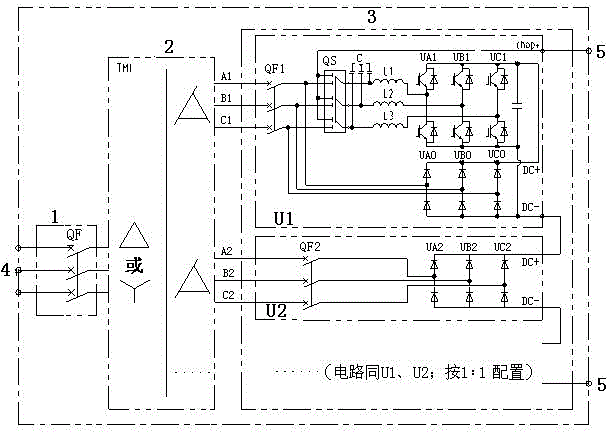

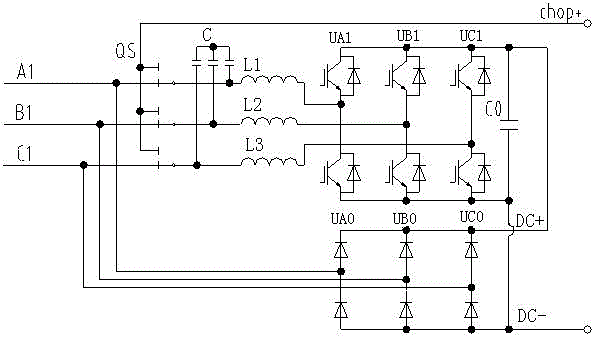

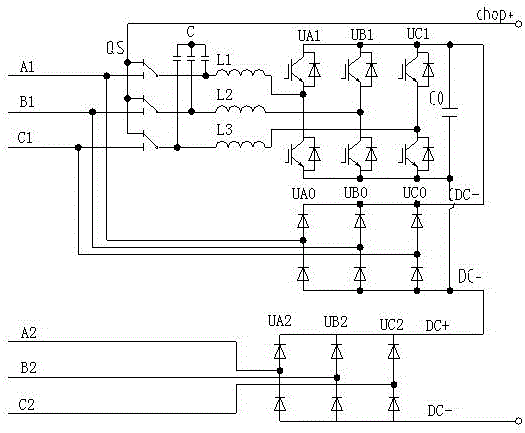

[0026] The specific embodiment of the present invention is shown in the figure.

[0027] In this embodiment, a low-cost and continuously adjustable DC deicing and reactive power compensation SVG device is composed of an input high-voltage switchgear 1 , a multi-winding phase-shifting step-down transformer 2 and a converter cabinet 3 . The output end of the input high-voltage switchgear 1 is connected to the input end of the multi-winding phase-shifting step-down transformer 2 ; the output end of the multi-winding phase-shifting step-down transformer 2 is connected to the converter cabinet 3 .

[0028] figure 1 Shown is the topological structure diagram of the main circuit of this embodiment.

[0029] The high-voltage circuit breaker QF input to the high-voltage switchgear 1 is connected to the power grid 4, and the remote opening / closing of the equipment can be realized by using the opening and closing of the QF. The output of QF is connected to the multi-winding phase-shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com