Electrodialysis separator and bipolar membrane electrodialysis device for producing organic acids

A technology of electrodialysis and separator, applied in the field of electrodialysis, can solve the problems of increased plate frame thickness and excessive fluid resistance, and achieve the effects of ensuring normal flow, reducing ion transfer resistance, and overcoming polarization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Electrodialysis separator and bipolar membrane electrodialysis device

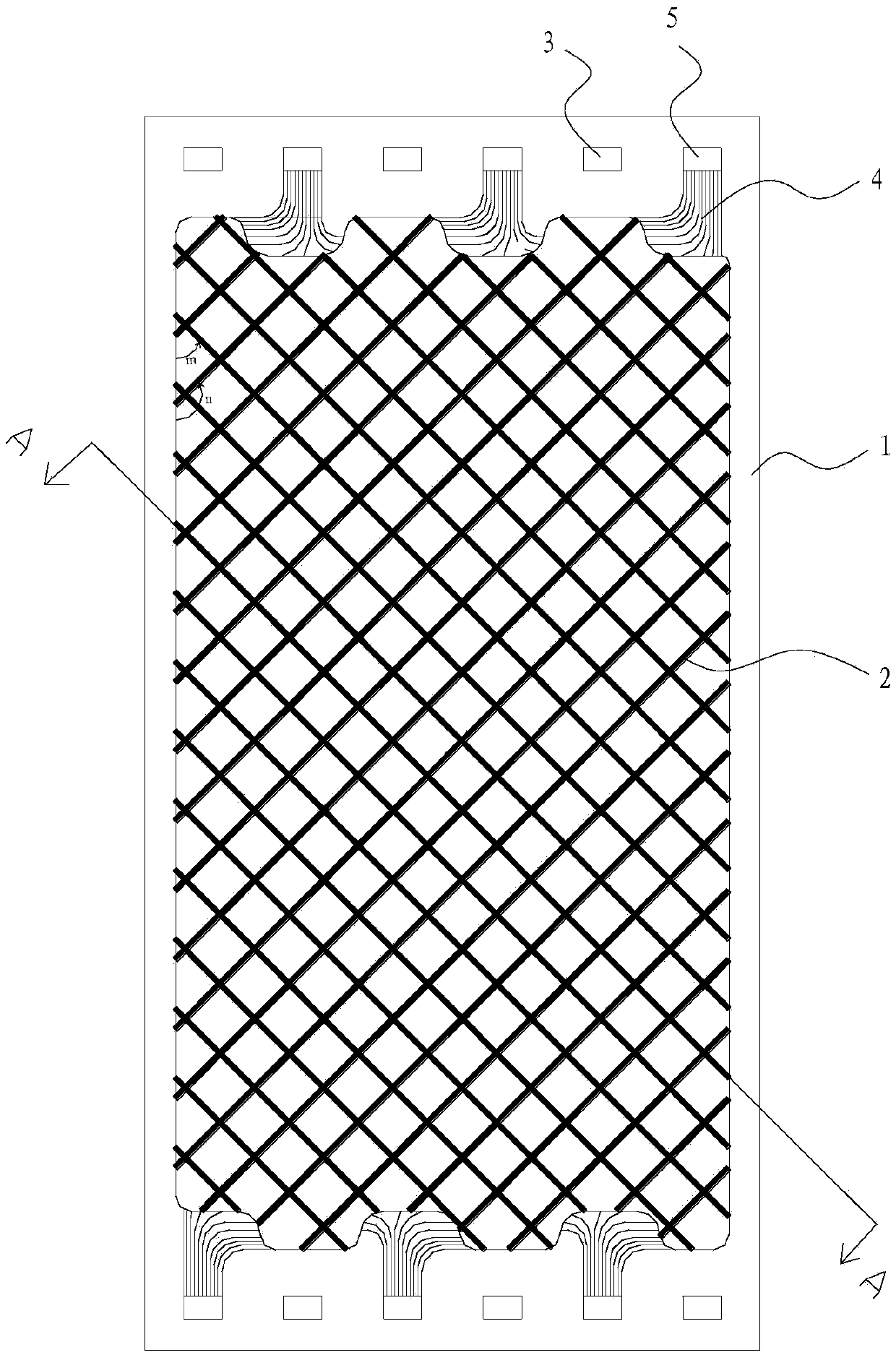

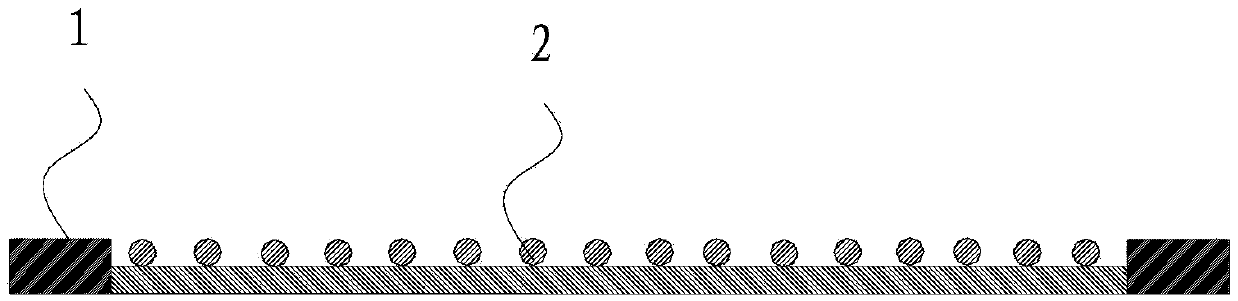

[0031] like figure 1 , figure 2 As shown, the electrodialysis separator of the present invention includes a plate frame 1 and a plate core separator 2 . The plate frame 1 has an inner cavity, and the plate core separator 2 is located in the inner cavity.

[0032] The upper and lower ends of the plate frame 1 are provided with rectangular liquid guiding holes. The liquid guiding holes are divided into two groups, one of which is an open liquid guiding hole 5 that communicates with the cavity of the plate frame through the water distribution channel 4, and the other group is. The closed liquid guiding holes 3 that are not communicated with the inner cavity of the plate frame, and the open liquid guiding holes 5 and the closed liquid guiding holes 3 are arranged at intervals.

[0033] The plate core separator 2 is formed by bonding ion-exchange fibers in a crisscross pattern, wherein the ...

Embodiment 2

[0037] This embodiment adopts the electrodialysis separator described in the above embodiment 1, wherein the plate frame material is EVA elastic thin plate, the thickness is 0.9mm, the plate frame size is 200×400mm, the thickness of the plate core separator is 0.9mm, and the plate frame is 0.9mm thick. The side length of the mesh in the heart separator is 2.0mm, the longitudinal ion exchange fiber and the long side of the plate frame are at a 45° angle (angle m), and the transverse ion exchange fiber is at a 135° angle (angle m) with the long side of the plate frame. n), the ion exchange fiber is cation exchange fiber, the material is sulfonated polysulfone, the diameter of each cation exchange fiber is 0.45mm, and the exchange capacity is 1.65mmol / g.

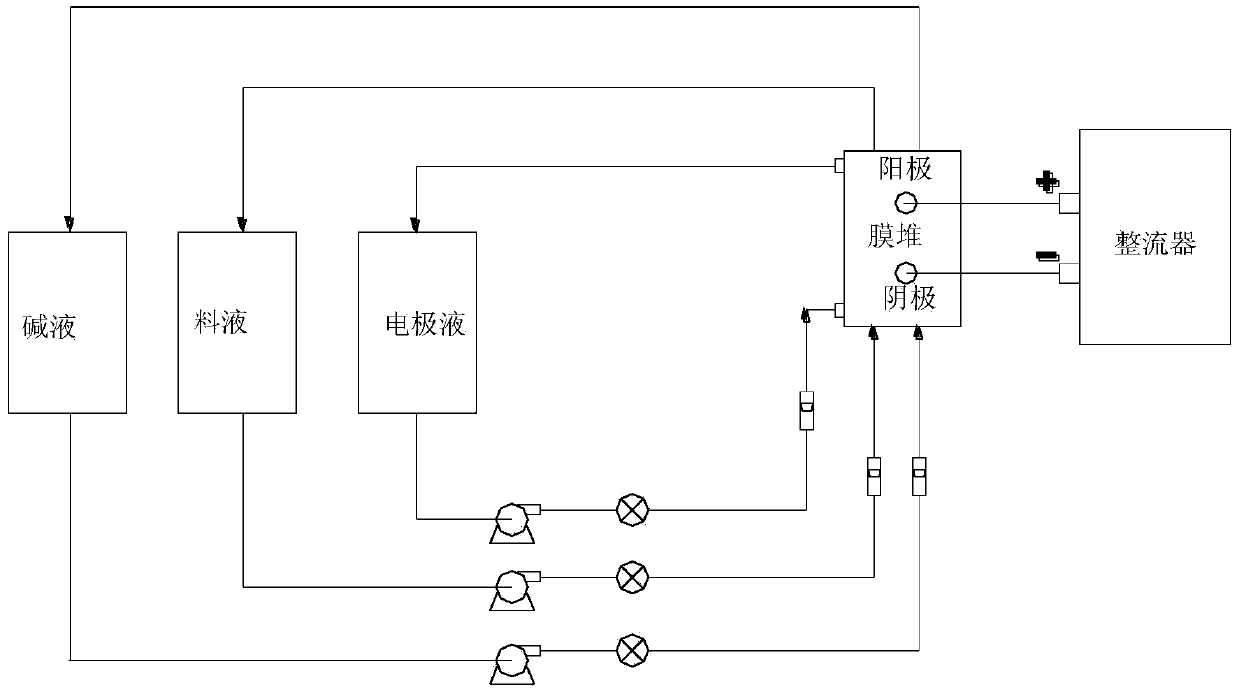

[0038]The bipolar membrane, cation exchange membrane (positive membrane), acid chamber separator and alkali chamber separator are formed into a membrane stack according to the installation sequence of the electrodialysis membran...

Embodiment 3

[0041] This embodiment adopts the electrodialysis separator described in the above-mentioned embodiment 1, wherein the plate frame material is EVA elastic thin plate, the thickness is 0.9mm, the plate frame size is 400×800mm, the thickness of the plate core separator is 0.9mm, and the plate frame is 0.9mm thick. The side length of the grid in the heart separator is 3.0mm, the longitudinal ion exchange fiber and the long side of the plate frame form an included angle of 45° (angle m), and the horizontal ion exchange fiber and the long side of the plate frame form an included angle of 135° (angle m). n), the ion exchange fiber is cation exchange fiber, the material is sulfonated polysulfone, the diameter of each cation exchange fiber is 0.45mm, and the exchange capacity is 1.65mmol / g.

[0042] The bipolar membrane, cation exchange membrane (positive membrane), acid chamber separator and alkali chamber separator are formed into a membrane stack according to the installation sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com