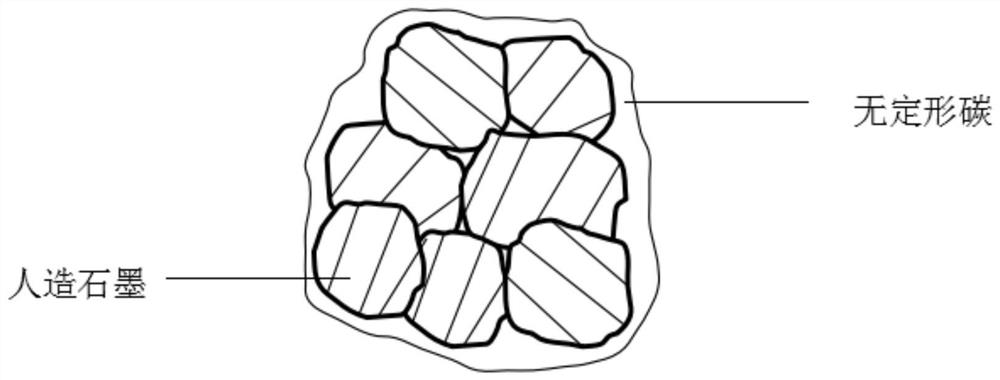

Fast-charging, high-compaction and high-capacity artificial graphite negative electrode material and preparation method thereof

An artificial graphite negative electrode and high-capacity technology, applied in the preparation/purification of graphite and carbon, chemical instruments and methods, etc., can solve the problems of unsatisfactory fast charging performance, failure to achieve high capacity, high compaction and fast charging performance, etc. Achieve the effects of shortening the transmission path, ensuring fast charging performance, and ensuring compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

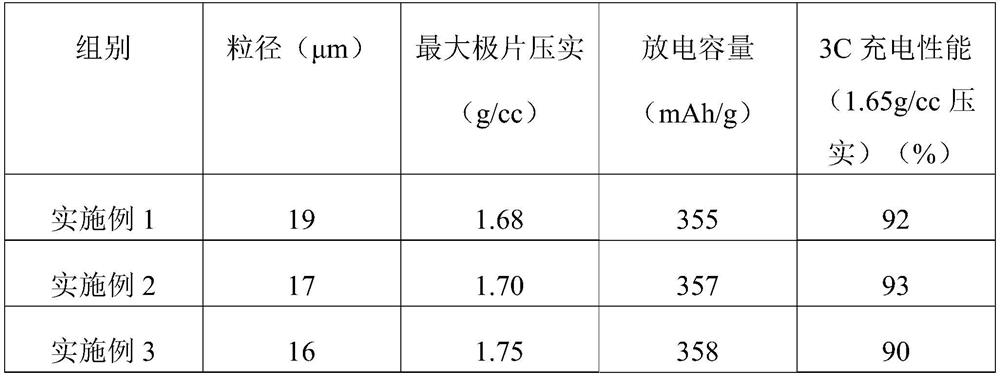

Embodiment 1

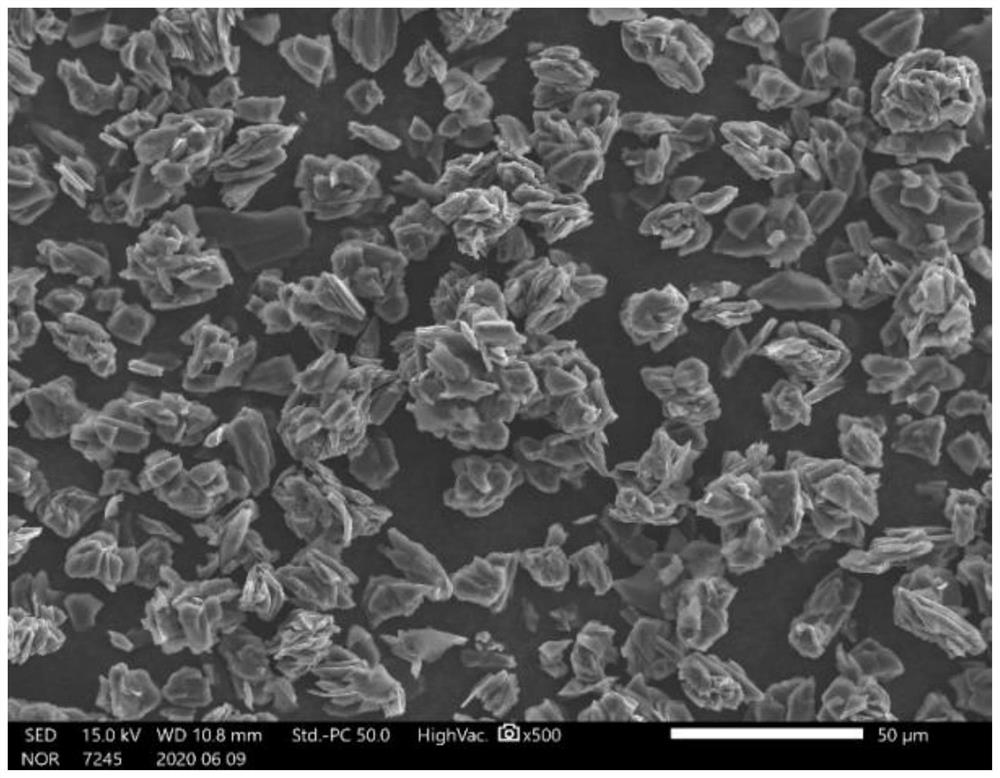

[0035] The present embodiment provides a method for preparing a fast-charging and high-capacity artificial graphite negative electrode material, comprising the following steps:

[0036] (1) pulverizing treatment: the petroleum coke is subjected to mechanical pulverization to obtain a pulverized material with a particle size D50 of 5 μm;

[0037] (2) Surface treatment: the pulverized material is subjected to shaping equipment, and the excessive fine powder and the edges and corners of the particles are removed under the condition of a rotating speed of 30 r / min, and the surface morphology of the particles is shaped and modified to obtain modified materials;

[0038] (3) granulation: the modified material and asphalt are uniformly mixed at a ratio of 100:3, added to a vertical kettle, and granulated at 500° C. for 6 hours to obtain a granulated material with a particle size D50 of 15 μm;

[0039] (4) Graphitization: the granulated material is subjected to high-temperature graphi...

Embodiment 2

[0042] The present embodiment provides a method for preparing a fast-charging and high-capacity artificial graphite negative electrode material, comprising the following steps:

[0043] (1) Milling treatment: the needle coke is subjected to mechanical grinding to obtain a pulverized material with a particle size D50 of 15 μm;

[0044] (2) Surface treatment: the pulverized material is subjected to shaping equipment, and the excessive fine powder and the edges and corners of the particles are removed under the condition of a rotating speed of 50 r / min, and the surface morphology of the particles is shaped and modified to obtain modified materials;

[0045] (3) granulation: the modified material and coal tar are uniformly mixed at a ratio of 100:10, added to a horizontal kettle, and granulated at 600° C. for 7 hours to obtain a granulated material with a particle size D50 of 30 μm;

[0046] (4) Graphitization: the granulated material is subjected to high-temperature graphitizatio...

Embodiment 3

[0049] The present embodiment provides a method for preparing a fast-charging and high-capacity artificial graphite negative electrode material, comprising the following steps:

[0050] (1) pulverizing treatment: the calcined coke is subjected to mechanical pulverization to obtain a pulverized material with a particle size D50 of 7 μm;

[0051] (2) Surface treatment: the pulverized material is subjected to shaping equipment, and the excessive fine powder and the edges and corners of the particles are removed under the condition of a rotating speed of 40 r / min, and the surface morphology of the particles is shaped and modified to obtain modified materials;

[0052] (3) granulation: the modified material and resin are uniformly mixed at a ratio of 100:18, added to a horizontal kettle, and granulated at 450° C. for 8 hours to obtain a granulated material with a particle size D50 of 22 μm;

[0053] (4) Graphitization: the granulated material is subjected to high-temperature graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com