Hard-biomass crusher

A crusher and biomass technology, applied in grain processing, etc., can solve problems such as unsatisfactory crushing effect, short crushing stroke, damaged motor, etc., and achieve long-term stability and reliability, long crushing stroke, and strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

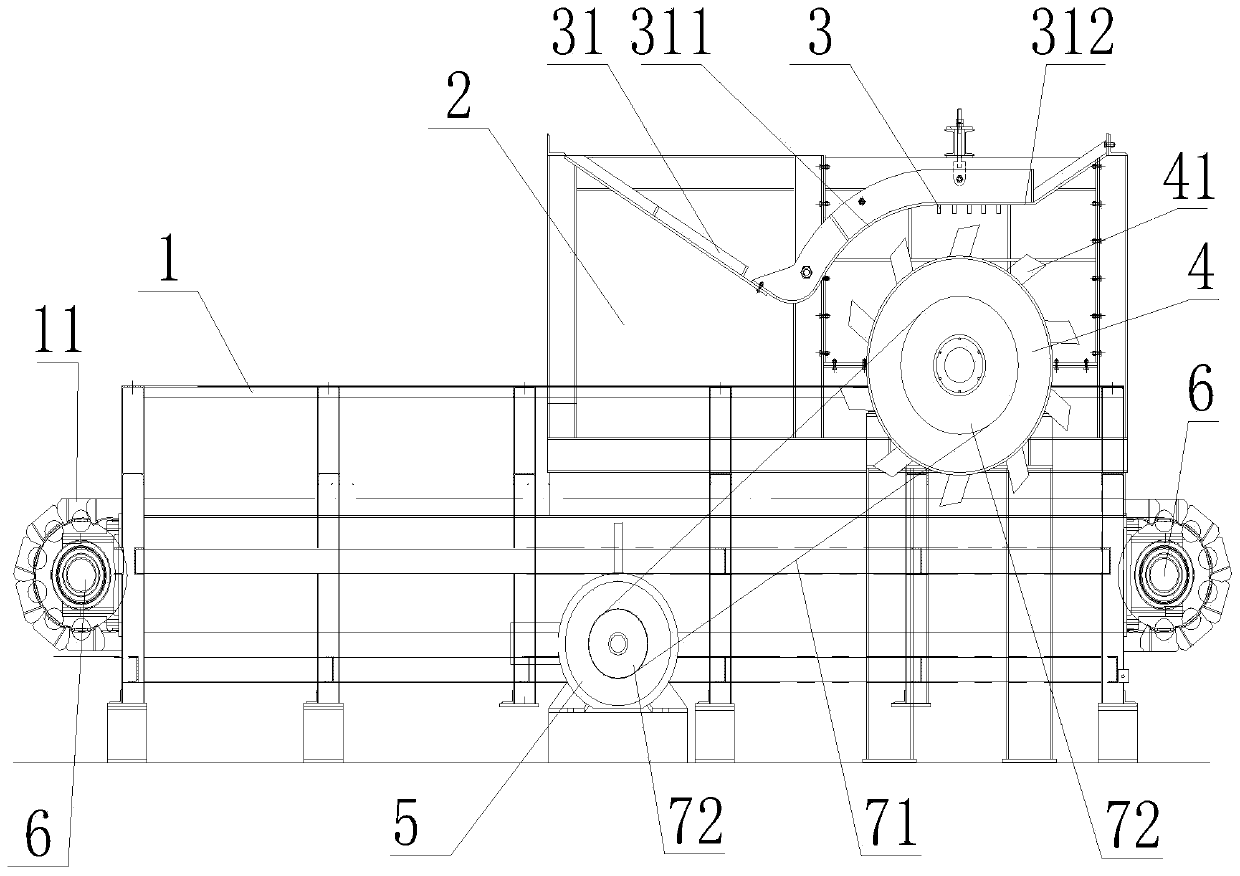

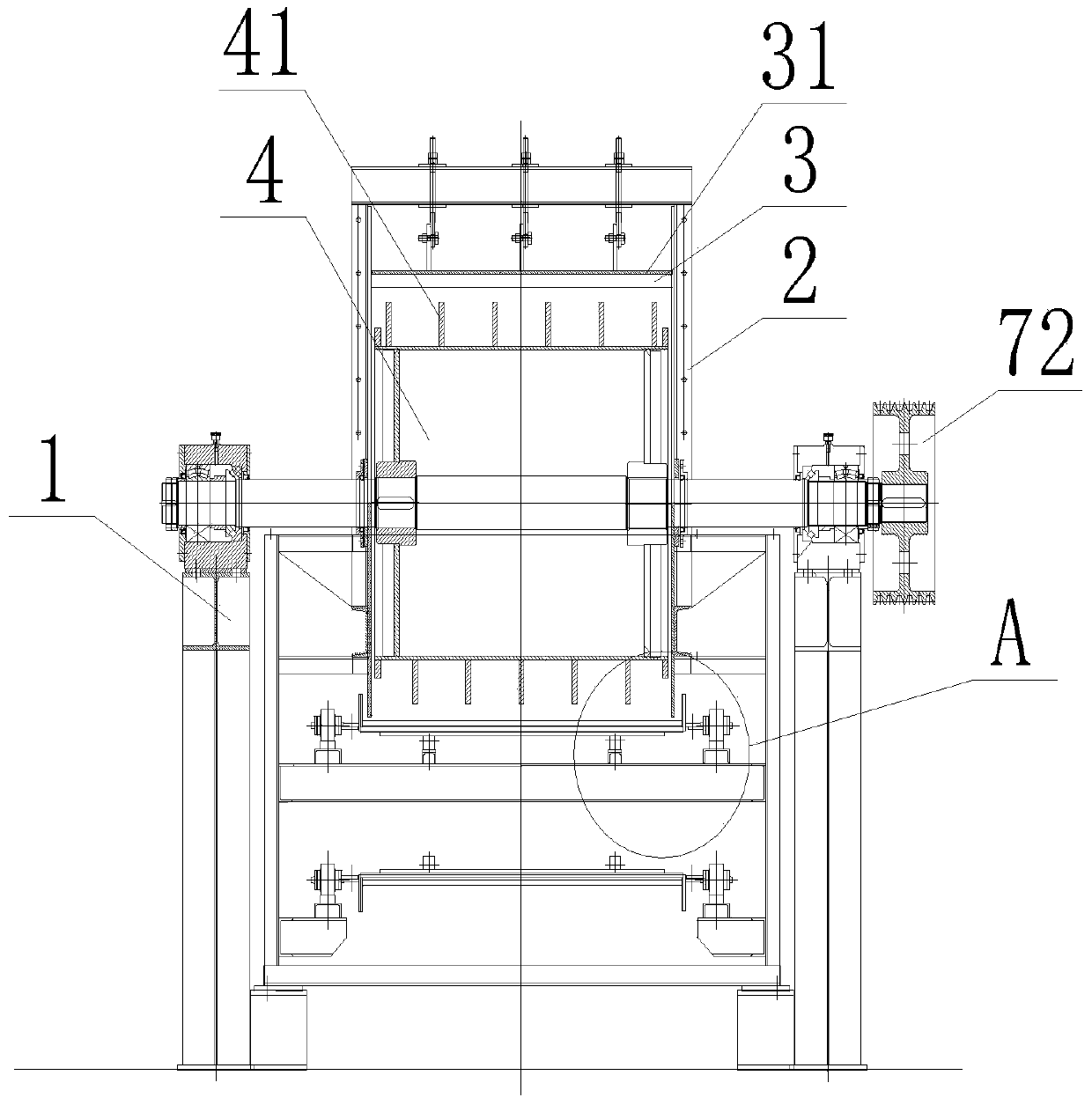

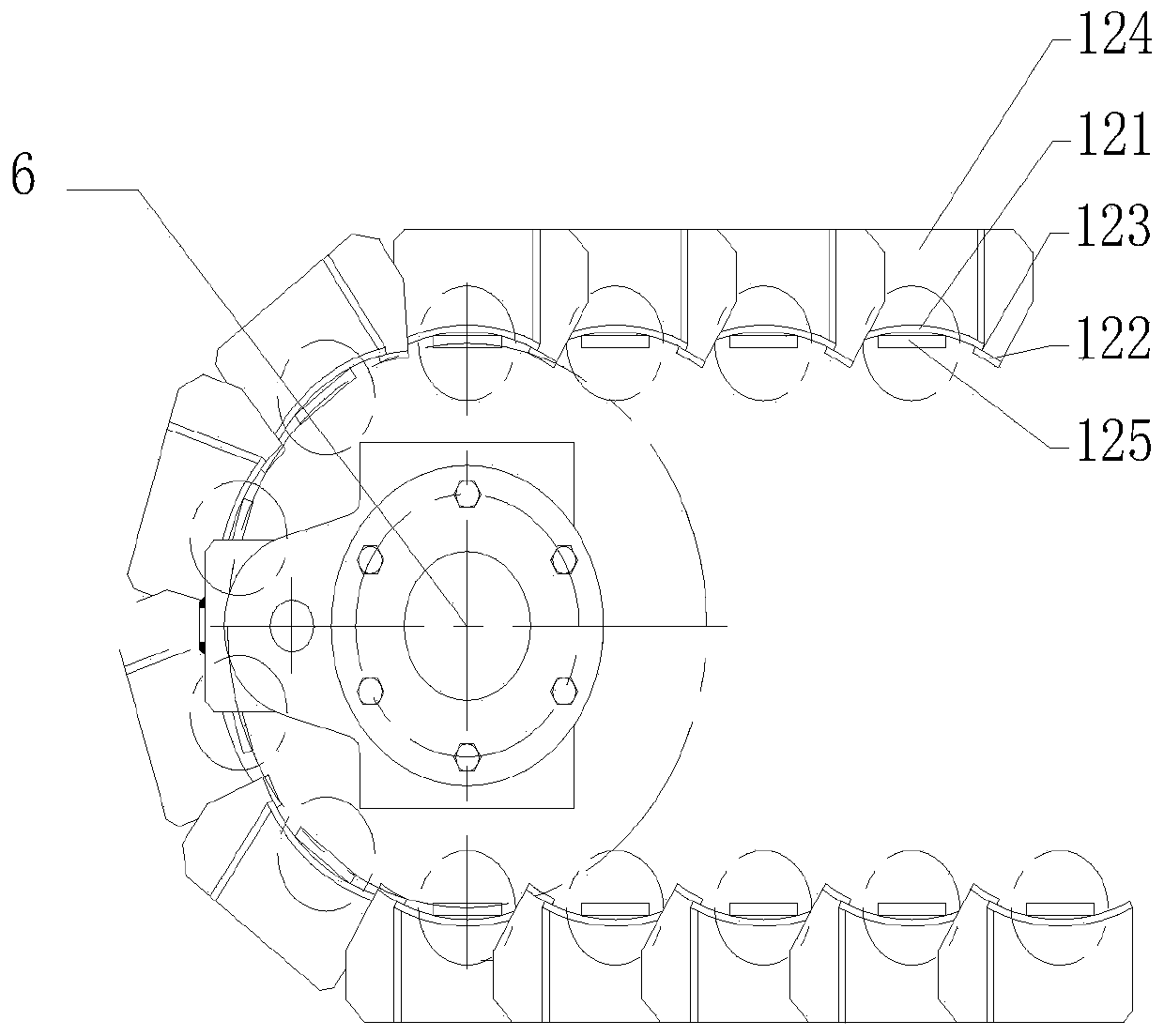

[0024] Such as Figures 1 to 4 As shown, the hard biomass crusher includes a frame 1 and a crusher casing 2 installed on the frame 1. The crusher casing 2 has a cavity, and the frame 1 is provided with a penetrating crusher casing. Conveyor belt 11 with 2 cavities. A rotary knife roller 4 is installed in the cavity of the crusher casing 2. The rotary knife roller 4 is located above the conveyor belt 11 and the axial direction of the rotary knife roller 4 is perpendicular to the conveyor belt. 11, the side wall of the rotary knife roller 4 is equipped with several rows of crushing blades 41, and the fixed knife rest 31 is installed in the cavity of the crusher casing 2, and the fixed knife rest 31 is located on the side of the rotary knife roller 4. Above, the side of the fixed knife holder 31 facing the rotary knife roller 4 is equipped with a number of fixed knife strips 3, and the rotary knife roller 4 is transmission-connected with a drive mechanism 5 for driving the rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com