Metal melt treatment method and device based on power ultrasound and pressure coupling

A metal melt and processing method technology, which is applied in the field of metal melt processing based on power ultrasonic and pressure coupling, can solve the problems of inconspicuous metal melt efficiency, improve safety and stability, improve efficiency and speed, The effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, a metal melt processing method based on power ultrasonic and pressure coupling includes the following steps:

[0034] (1) Preheat the mold cavity until the temperature of the inner surface of the mold cavity wall reaches 250°C; the material of the mold cavity is H13 steel, lubricated with graphite oil;

[0035] (2) After heating the metal melt to the preset temperature, pour it into the mold cavity, and turn on the heat preservation heater at the same time to keep the mold cavity warm;

[0036] Among them, the preset temperature of the metal melt is in the temperature range of 10-100°C above the liquidus line; when the heat preservation heater heats the mold cavity, the temperature of the inner side of the mold cavity is kept at 500-550°C;

[0037] (3) The punch of the hydraulic press applies pressure to the metal melt, and at the same time, the power ultrasonic generator performs power ultrasonic vibration on the metal melt; through the cooperative ...

Embodiment 2

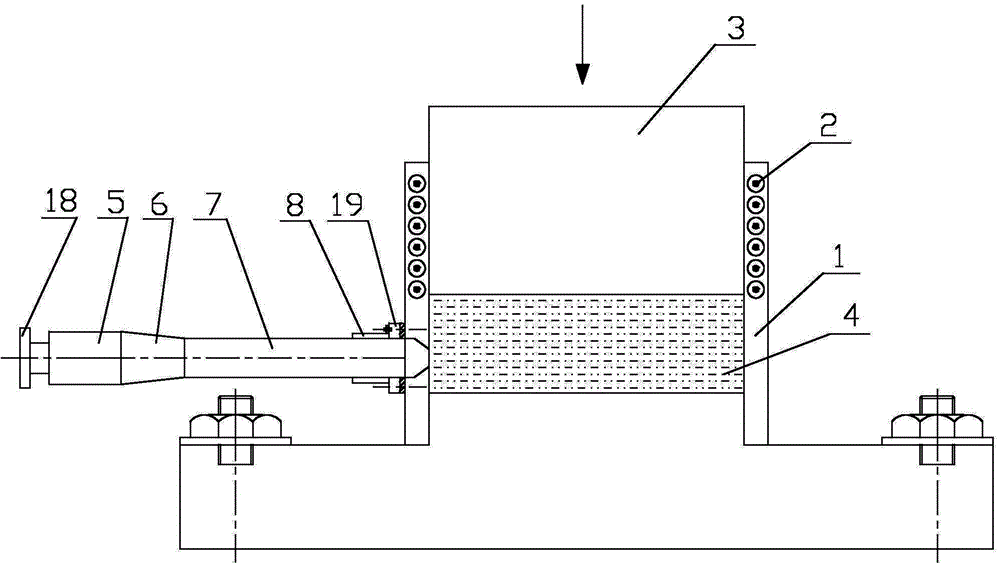

[0041] In this embodiment, a metal melt processing device based on power ultrasonic and pressure coupling for the method described in Embodiment 1, such as figure 1As shown, including mold cavity 1, heat preservation heater 2, punch 3 and power ultrasonic generator, metal melt 4 is placed in the mold cavity, the cavity wall of the mold cavity is provided with heat preservation heater, and the punch is set Above the mold cavity, after the power ultrasonic generator passes through the wall of the mold cavity, it is inserted into the molten metal from the side of the mold cavity.

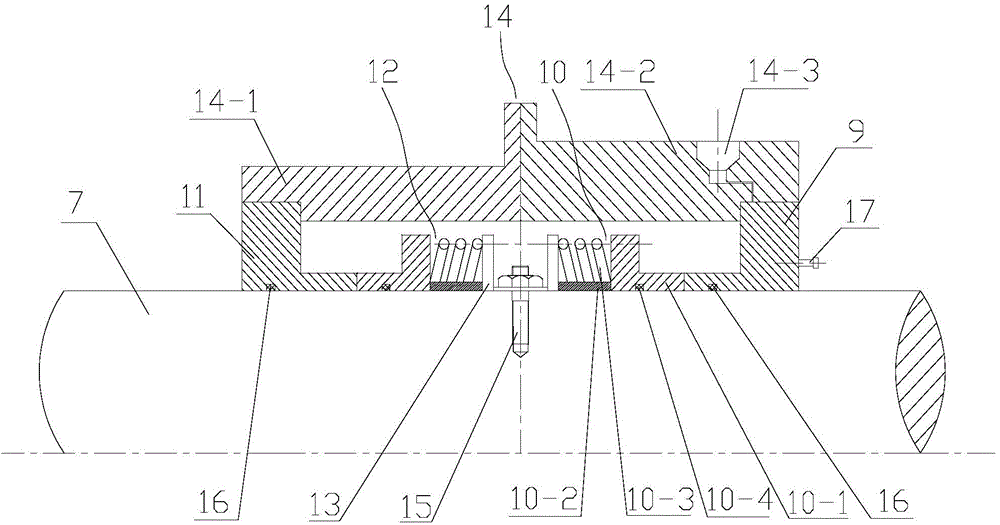

[0042] The power ultrasonic generator includes ultrasonic transducer 5, ultrasonic horn 6 and ultrasonic introduction rod 7 connected in sequence, the end of the ultrasonic introduction rod has a rod tip, and after the rod tip passes through the cavity wall of the mold cavity, it passes through the cavity wall of the mold cavity. The sides of the cavity are inserted into the metal melt.

[0043] A sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com