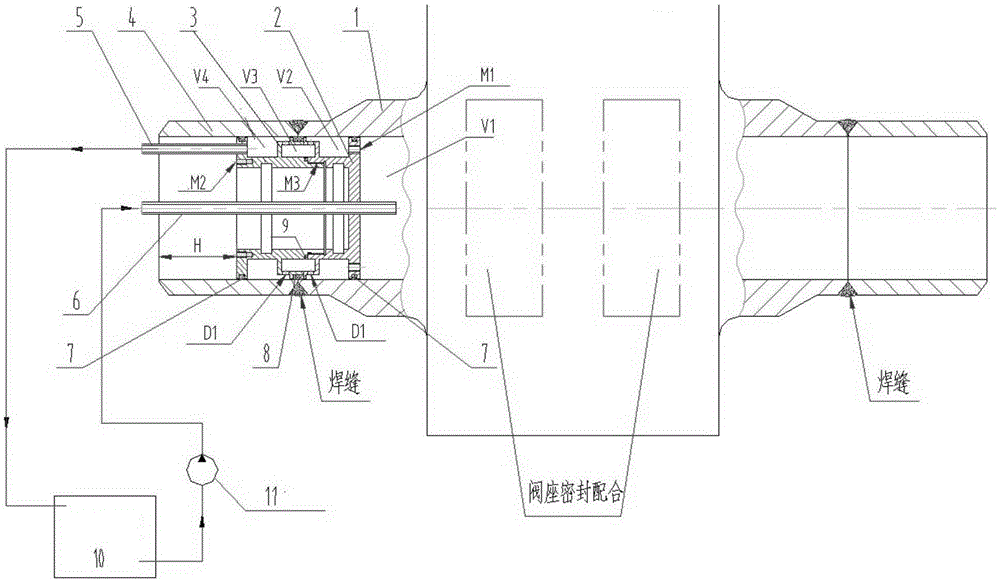

Cooling device welded between subsea valve and transition pipe

A technology of cooling device and transition pipe, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of insignificant spray cooling effect, limited on-site operation, and affecting the performance of valve products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

[0021] In marine underwater oil and gas, petroleum (petroleum and natural gas) exploitation and production devices, underwater valves and underwater actuator devices are used. The connection between underwater valves and various underwater production devices can be flanged (water depth less than 300 meters) or welded connections (water depth greater than 300 meters). For valve devices that adopt welded connections, they must be connected, assembled and debugged on land before they can be launched into the water. In the land welding process, the underwater valve device needs to be welded with the transition pipe and the valve welding end before leaving the factory, and then it can be welded and assembled with other devices before leaving the factory.

[0022] In the underwater valve manufacturing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com