Splitting device for splitting windscreen wiper pre-forming piece

A cutting device and wiper technology, applied in metal processing and other directions, can solve problems such as low work efficiency and inaccurate manual cutting, and achieve the effects of improving work efficiency, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

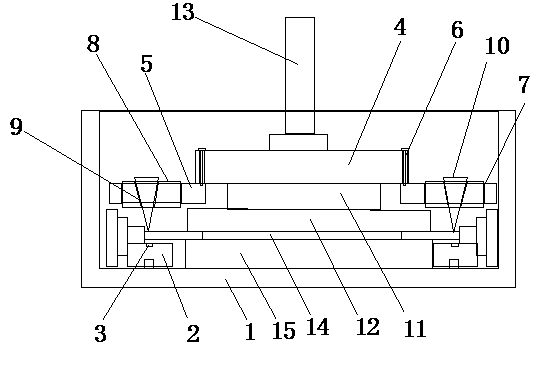

[0013] Example 1, such as figure 1 As shown, a cutting device for cutting a wiper preform is characterized in that: the cutting device is composed of a wiper preform flat part and a manual dividing part, and the wiper preform flat part is a concave shaped and elongated carrier seat 1, a group of pads 2 are arranged at the inner bottom of the carrier seat 1, and each pad 2 top is provided with an edge groove 3, and the manual dividing part includes a connecting beam 4, The cutter sets respectively arranged at both ends of the connecting beam 4 and the pressing block set arranged at the center position of the bottom of the connecting beam 4 . The push handle 13 is connected above the connecting beam 4 .

[0014] Further, the tool set includes a connection block 5 arranged on the outer side of the bottom surface of the connection beam 4, the connection beam 4 and the connection block 5 are connected by bolts 6, and a socket is provided in the connection block 5 7. A tool seat 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com