Machine head flow channel corner non-dead-angle structure

A technology without dead ends and runners, applied in the field of plastic blown film, can solve problems affecting product quality, achieve the effect of meeting process requirements, smooth flow, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

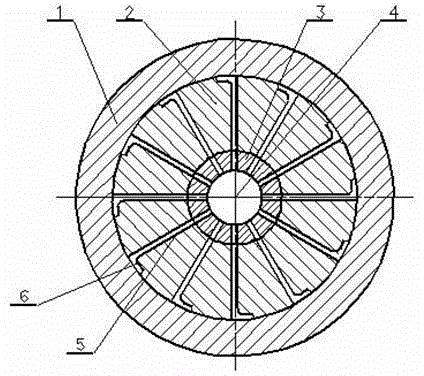

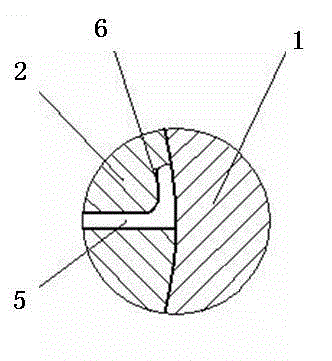

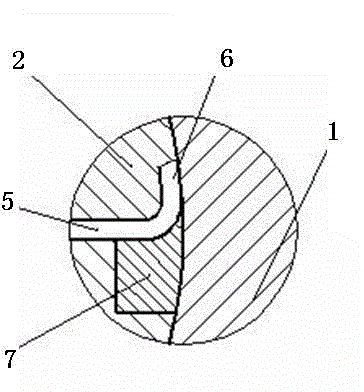

[0012] Such as image 3 As shown, the present invention is a structure with no dead angle at the corner of the flow channel of the machine head. The flow channel 3 of the machine head is installed on the main flow channel 4, and the flow channel on the flow channel 3 of the machine head and the flow channel 5 installed on the flow channel spiral body 2 outside it Corresponding to the communication, the machine head cover 1 is installed on the outside of the flow channel helix 2, and the opening at one end of the head cover 1 is provided with a spiral flow channel 6 at the opening of the flow channel 5, and the corner where the flow channel 5 is connected to the spiral flow channel 6 An insert 7 is installed at the center, and the insert 7 is installed between the flow channel helix 2 and the machine head jacket 1. The flow channel surface of the insert 7 is arc streamlined, and by adding the arc streamline insert 7 The dead angle disappears, and the material flow at the corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com