Industrial liquid-containing sludge drying treatment device

A sludge drying and treatment device technology, which is applied in the direction of temperature control sludge treatment, dehydration/drying/thickened sludge treatment, etc., to achieve the effect of low oil content and moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is mainly used for the drying treatment of industrial liquid waste, petroleum and chemical residual liquid sludge. By continuously maintaining the heat exchange efficiency between the treated object and the drying treatment device, the liquid sludge is carried out in a high temperature manner. Harmless or reduction treatment.

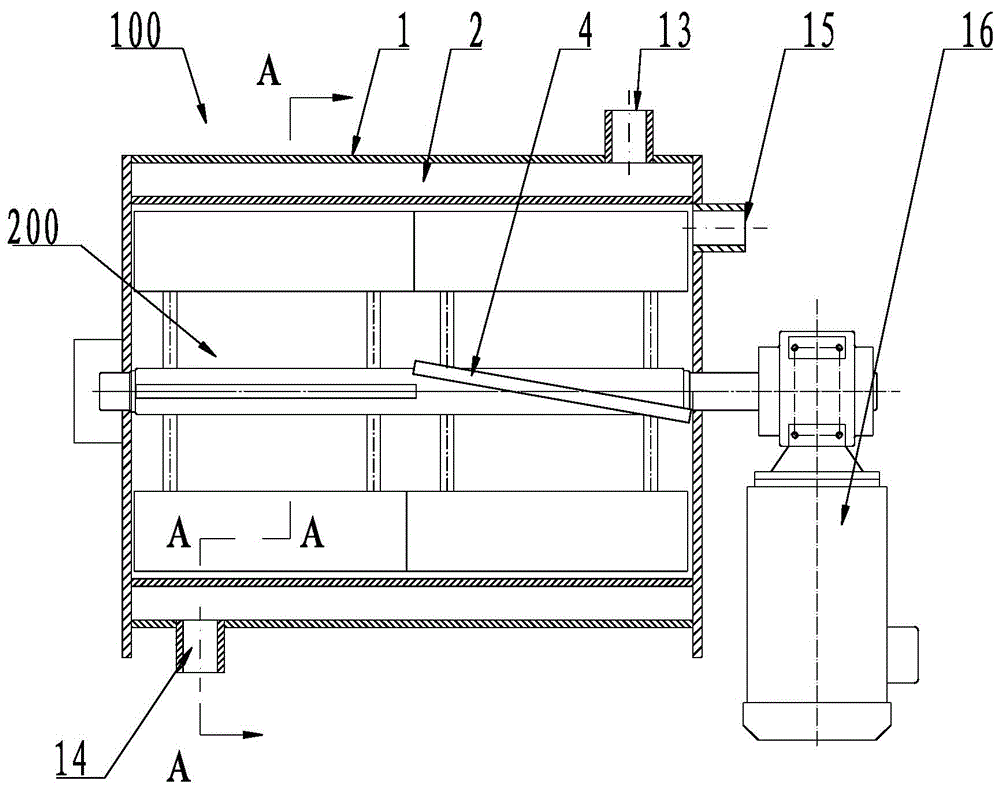

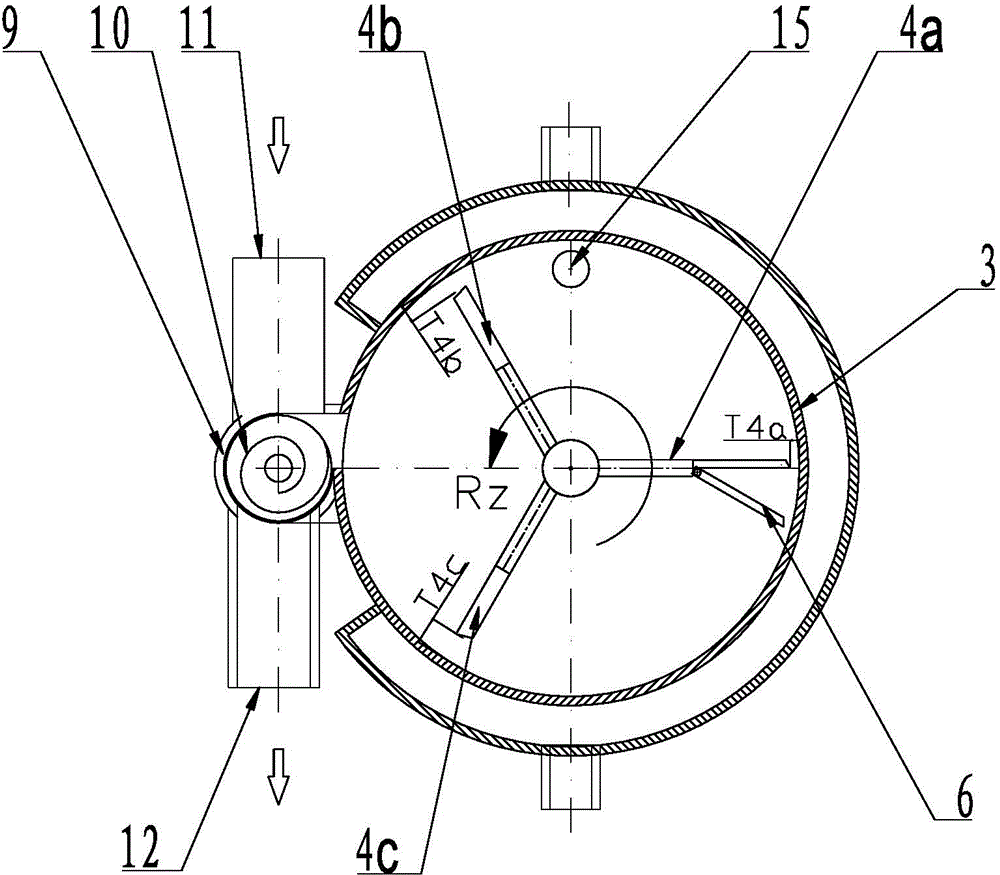

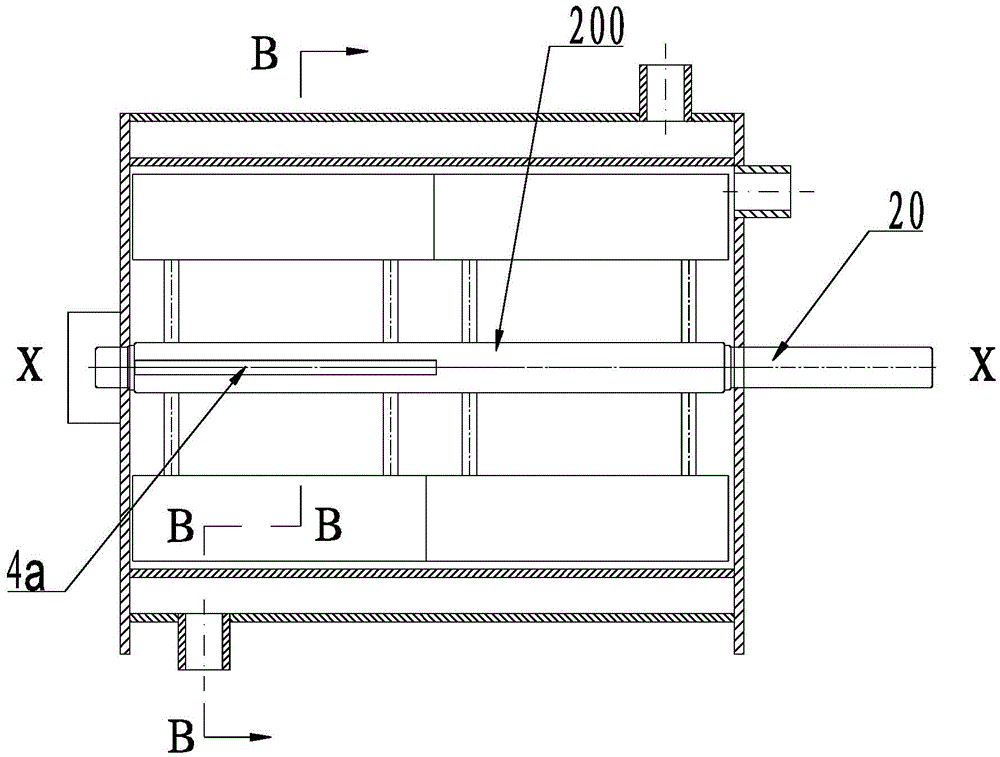

[0030] The structure and principle of the industrial liquid sludge drying treatment device in the embodiment of the present invention are as follows: Figure 1 to Figure 10 shown.

[0031] Such as figure 1 , figure 2 and Figure 7 to Figure 9 As shown, the heating tank of the industrial liquid sludge drying treatment device has a horizontal cylindrical tank body 100, and the outer shell of the tank body 100 is a double-layer structure, including an outer wall 1 and an inner wall 3, and between the outer wall 1 and the inner wall 3 It is the heating interlayer 2, and the interior of the heating interlayer 2 passes through high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com