Film covering glue and preparation method thereof

A technology of laminating adhesive and adjusting temperature, applied in the direction of adhesive, adhesive type, adhesive additive, etc., can solve the problems of poor surface abrasion resistance, single color and low viscosity of the film-forming object, and achieve good surface abrasion resistance , Simple operation, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of coating adhesive provided by the invention comprises the following steps:

[0018] (1) Add 880-900 parts by weight of water into the reaction kettle, stir, adjust the temperature to 40-50°C, then add 75-80 parts by weight of polyvinyl alcohol, heat up to 75-80°C and keep warm for 42-48min ;

[0019] (2) Adjust the temperature to 80-85°C, add 135-150 parts by weight of formaldehyde, raise the temperature to 90-95°C, keep warm for 55-65min, adjust the pH value to 4.4-4.6, and then add 450-500 parts by weight of melamine modified phenolic Resin adhesive, stir evenly;

[0020] (3) Adjusting the pH value to 9.4-9.6 to obtain the coating glue.

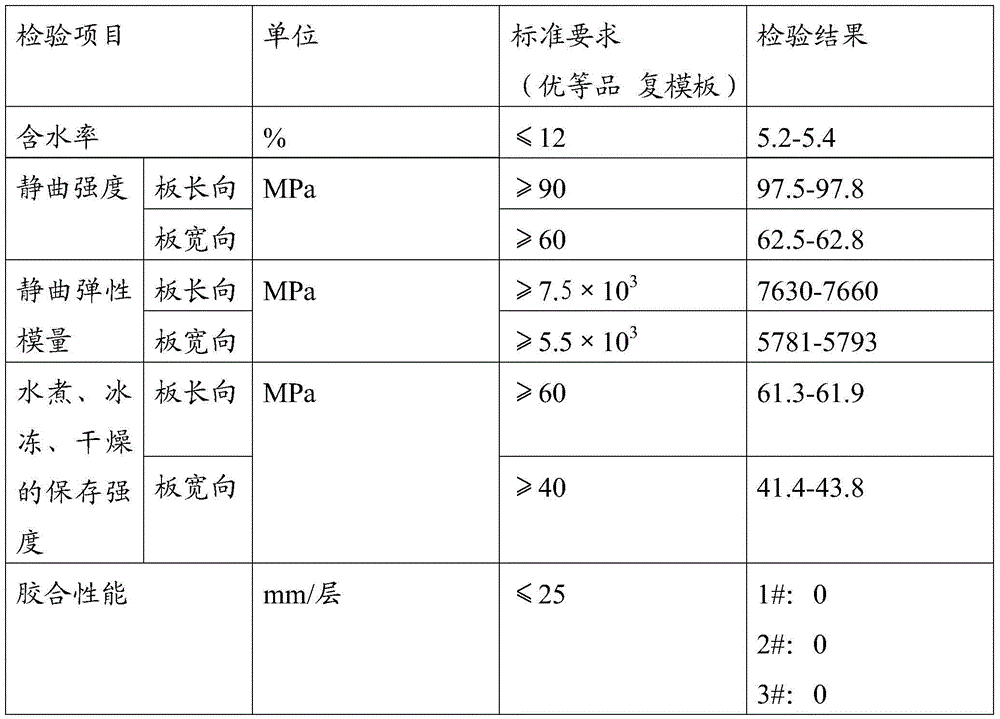

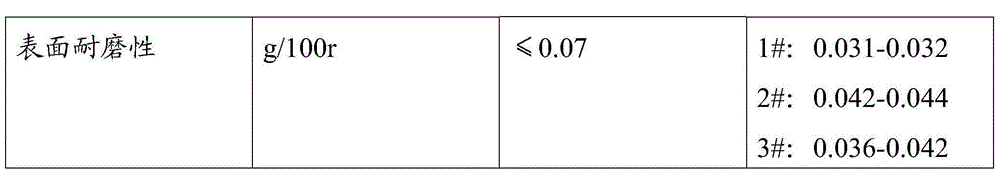

[0021] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0022] (1) the film-coated glue prepared by the present invention is reddish-brown transparent, which overcomes the single problem of the color of the film-coated glue in the prior art;

[00...

Embodiment 1

[0033] 1. Put 880 kg of water into the reaction kettle, start the agitator to stir, and raise the temperature to 45°C, and put in 75 kg of polyvinyl alcohol.

[0034] 2. Raise the temperature to 78°C, the polyvinyl alcohol will gradually dissolve and become transparent, keep warm for 45 minutes, and keep the temperature between 80°C and 85°C to ensure the complete dissolution of the polyvinyl alcohol;

[0035] 3. Add 135 kg of formaldehyde, raise the temperature to 90°C, and keep it warm for 60 minutes. At this time, extract a small amount of the product in the reaction kettle and measure it with 4 cups at 40°C. Add hydrochloric acid with a mass concentration of 30%, adjust the pH value to 4.5, and add 450 kg of melamine-modified phenolic resin adhesive. Add the sodium hydroxide that mass concentration is 99%, regulate pH value to be 9.5; In reaction, the hydrochloric acid that mass concentration is 30% and the sodium hydroxide that mass concentration is 99% not only play the ...

Embodiment 2

[0039] 1. Put 900 kg of water into the reaction kettle, start the agitator to stir, and raise the temperature to 50°C, and put in 80 kg of polyvinyl alcohol.

[0040] 2. Raise the temperature to 80°C, the polyvinyl alcohol gradually dissolves and becomes transparent, keep warm for 48 minutes, and the temperature is controlled between 80°C-85°C to ensure that the polyvinyl alcohol is completely dissolved.

[0041] 3. Add 150 kg of formaldehyde, raise the temperature to 90°C, and keep it warm for 65 minutes. At this time, extract a small amount of the product in the reaction kettle, and measure it with 4 cups at 40°C. The measured viscosity value is 22〃, and the reaction kettle Add hydrochloric acid with a mass concentration of 30%, adjust the pH value to 4.6, and add 500 kg of melamine-modified phenolic resin adhesive. Add the sodium hydroxide that mass concentration is 99%, regulate pH value to be 9.6; In reaction, the hydrochloric acid that mass concentration is 30% and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com