Downhole drilling azimuth measurement system and measurement method

A measurement system and azimuth angle technology, applied in the direction of buildings, etc., can solve the problems of large measurement error, large factor influence, large reading error, etc., and achieve the effect of easy operation, little influence of human factors, and reduced adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

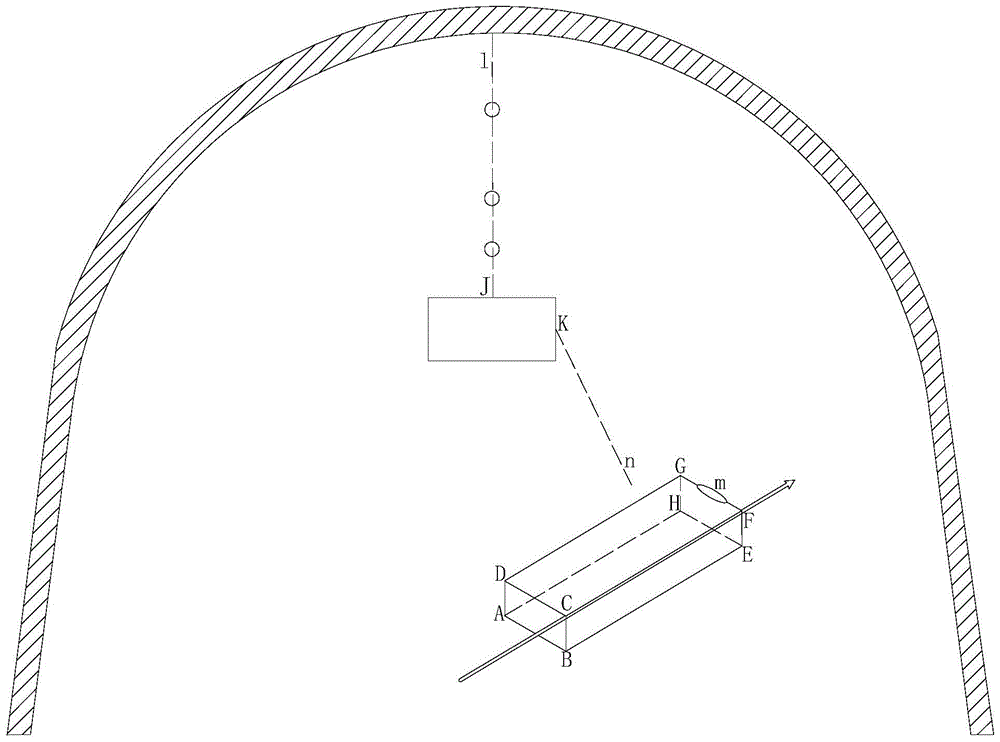

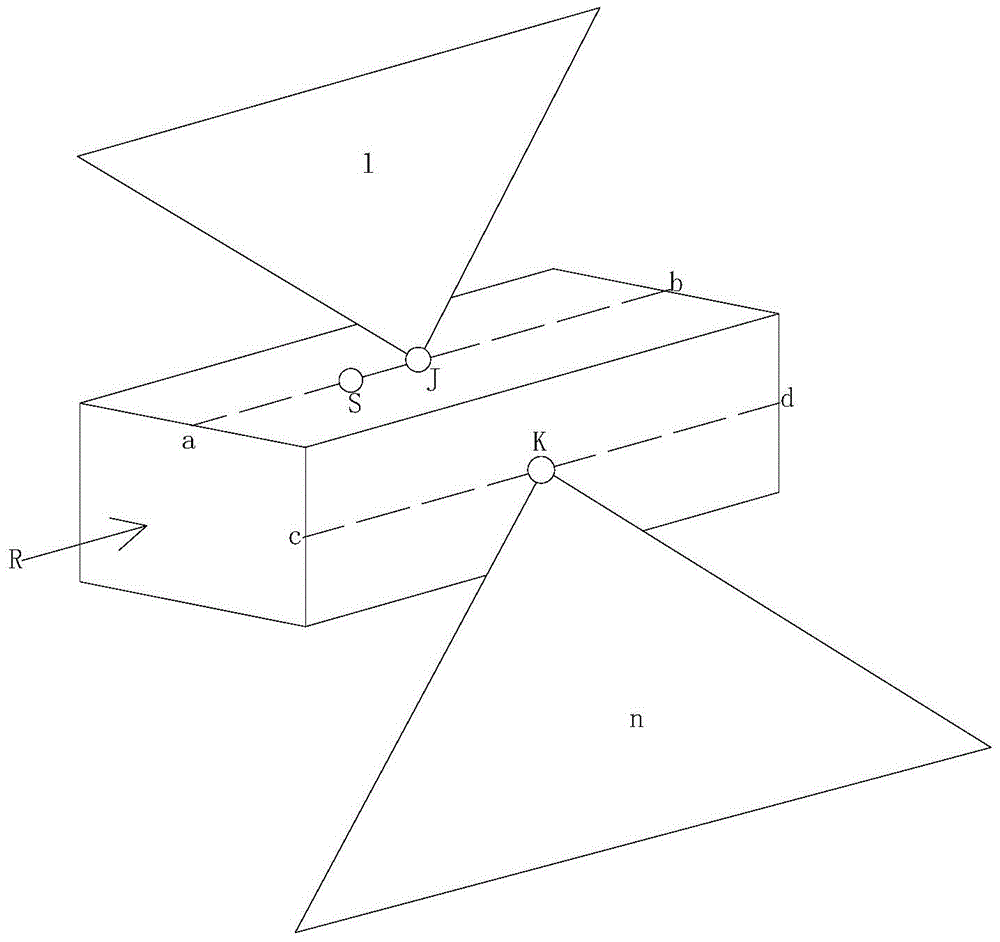

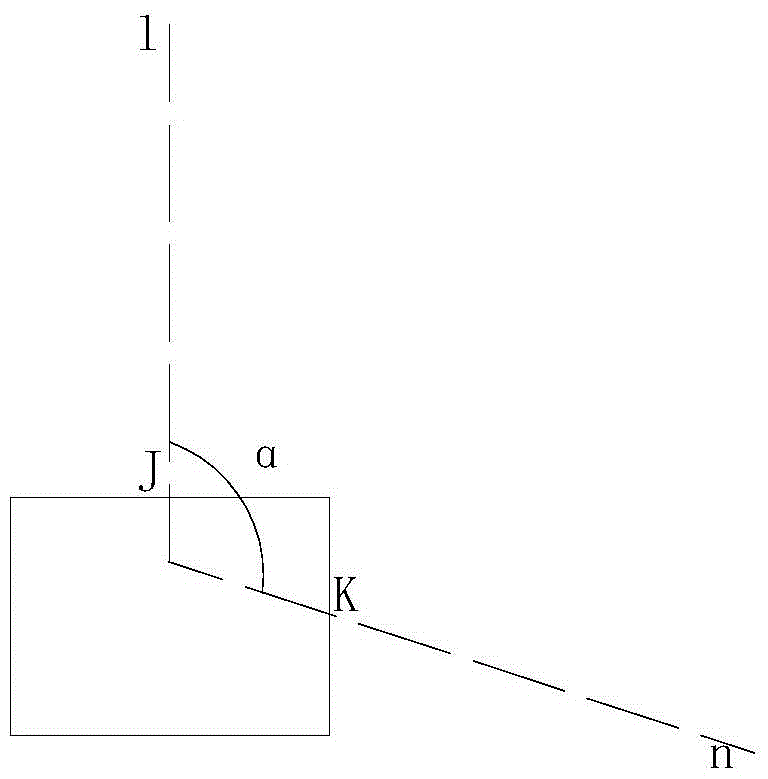

[0049] As shown in the figure: the downhole drilling azimuth measurement system of this embodiment includes a marker 1 and a measurement host 2; the marker 1 includes a line light source for generating a first exit plane 1 that coincides with the centerline of the roadway The emission device I3 and the line source emission device II4 for generating the second exit plane n intersecting the measurement host 2, the projection of the extended intersection line of the first exit plane l and the second exit plane n and the centerline of the roadway on the horizontal plane parallel to each other, the angle between the first exit plane l and the second exit plane n can be adjusted; the measuring host 2 includes an upper photosensitive plane and a side photosensitive plane for intersecting with the second exit plane n, the upper photosensitive plane and the side photosensitive plane The intersecting lines form the azimuth and inclination angles that can be consistent with the setting ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com