Cable bridge wall-following horizontal installing mechanism

A cable tray and installation mechanism technology, applied in electrical components, mechanical equipment, fixtures, etc., can solve the problems of easy corrosion, shortened life of cover plates and brackets, easy to rust, etc., and achieve strong corrosion resistance and stability. Good, firm and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

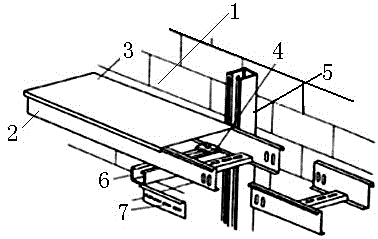

[0017] Such as figure 1 As shown, a cable bridge horizontal installation mechanism along the wall includes a wall 1, a cable bridge 2, a cover plate 3, a plywood 4, a channel steel 5, a bracket 6, and a connecting piece 7, and the wall 1 is fixedly installed with a channel steel 5. A bracket 6 is installed on the channel steel 5, a connecting piece 7 is arranged on the bracket 6, a cable bridge 2 is installed on the upper end of the bracket 6, and a cover plate 3 is installed on the upper end of the cable bridge 2, The bracket 6 is also provided with a splint 4, the splint 4 is used to fix and clamp the cable tray 2, the cover plate 3 is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com